Determining the influence of wheelset arrangement in the model 18-100 bogies on the level of steering efforts in the wheel-rail flange contacts

DOI:

https://doi.org/10.15587/1729-4061.2024.304328Keywords:

railroad transport, 18-100 bogies, steering forces, flange, interaction of wheels and railsAbstract

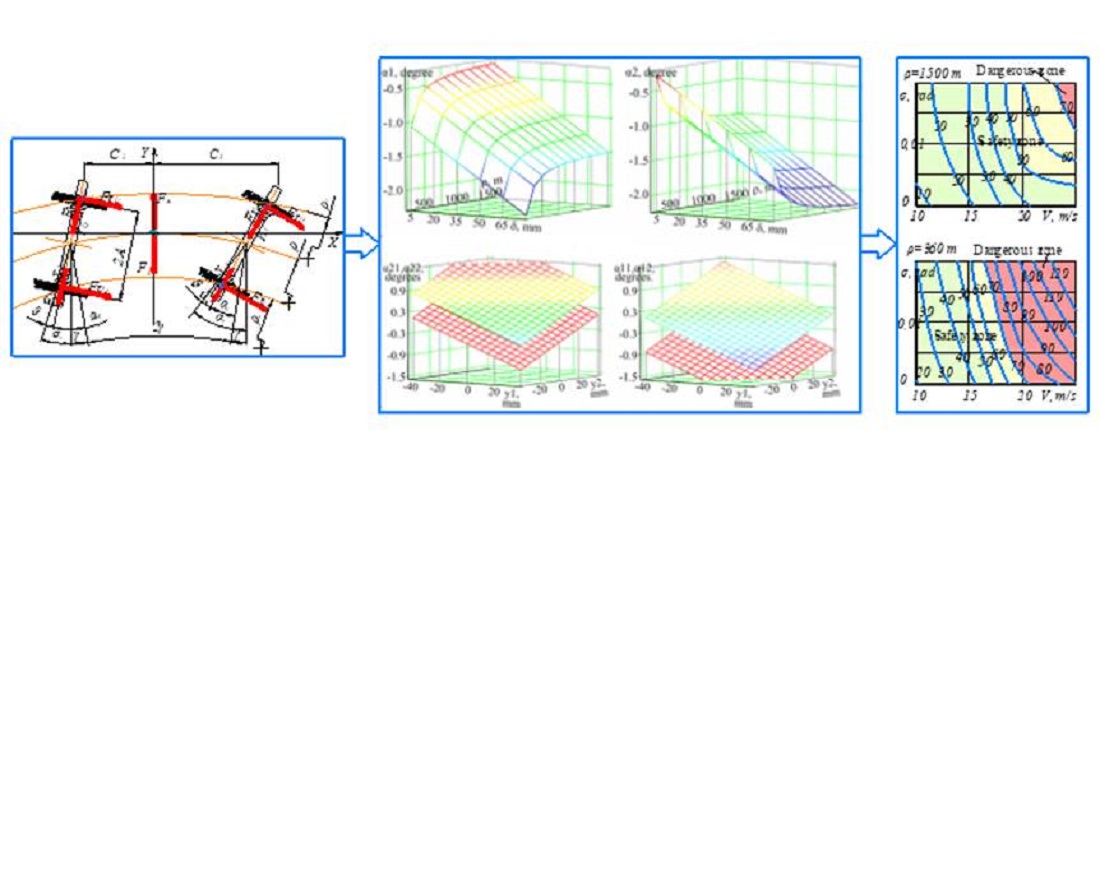

The object of this study is the process of directing the bogies of model 18-100 freight cars along a rail track, in particular, along curved sections of the track. The task to be solved was to determine the influence of wheelset arrangement on the level of steering forces in the flange contacts.

A calculation diagram and a mathematical model of fitting the bogie into the curved section of the track have been built. The bogie loading scheme by external forces, including lateral rocking forces acting on the car in a curve, has been refined. In this case, the method of pseudo-statics of the mechanical system, which is a system of nonlinear algebraic equations, was applied. The calculation module Given-Find in the Mathcad software package (USA) was used to solve the mathematical model.

It was established that the misalignment of wheelsets in the frames of model 18-100 bogies was of an accumulative nature. At the maximum operating angles of misalignment of wheelsets, the lateral steering forces in the flange contacts increase by 40–60 % compared to the rated setting. These angles can be up to 0.015 rad (0.85 degrees).

The field of practical application of the results is railroad transportation, in particular, the system of maintenance and repair of freight cars on bogies of the 18-100 model. At the same time, the condition for the practical application of the research results is the expediency of introducing into the maintenance system the technological operation of controlling the deviation of wheelset arrangement in the bogie relative to the rated one.

The current study will contribute to the construction of a measuring system for monitoring the deviation of wheelset arrangement in the bogie relative to the rated one. This proves the expediency of introducing into the trolley maintenance system the technological operation of controlling the deviation of wheelsets and designing a device for monitoring this parameter

References

- Domin, R., Domin, I., Cherniak, G., Mostovych, A., Konstantidi, V., Gryndei, P. (2016). Investigation of the some problems of running safety of rolling stock on the Ukrainian railways. Archives of Transport, 40 (4), 15–27. https://doi.org/10.5604/08669546.1225459

- Fomin, O., Lovska, A. (2021). Determination of dynamic loading of bearing structures of freight wagons with actual dimensions. Eastern-European Journal of Enterprise Technologies, 2 (7 (110)), 6–14. https://doi.org/10.15587/1729-4061.2021.220534

- Knothe, K. (2008). History of wheel/rail contact mechanics: from Redtenbacher to Kalker. Vehicle System Dynamics, 46 (1-2), 9–26. https://doi.org/10.1080/00423110701586469

- Bahrov, O. M. (2016). Bokovi ramy vizkiv vantazhnykh vahoniv. Ekspluatatsiya. Problemy ta yikh vyrishennia. Zaliznychnyi transport Ukrainy, 1-2, 29–34. Available at: http://nbuv.gov.ua/UJRN/ZTU_2016_1-2_7

- Pires, A. C., Pacheco, L. A., Dalvi, I. L., Endlich, C. S., Queiroz, J. C., Antoniolli, F. A., Santos, G. F. M. (2021). The effect of railway wheel wear on reprofiling and service life. Wear, 477, 203799. https://doi.org/10.1016/j.wear.2021.203799

- Zub, I., Sapronova, S. (2022). Influence of deviations in the position of wheel pairs in a freight-car on the guiding forces. Transport Systems and Technologies, 40, 63–77. https://doi.org/10.32703/2617-9040-2022-40-6

- Koshel, O., Sapronova, S., Tkachenko, V., Buromenska, M., Radkevich, M. (2021). Research of Freight Cars Malfunctions in Operation. Proceedings of 25th International Scientific Conference. Transport Means 2021, 589–592. Available at: https://transportmeans.ktu.edu/wp-content/uploads/sites/307/2018/02/Transport-Means-2021-Part-II.pdf

- Hu, Y., Watson, M., Maiorino, M., Zhou, L., Wang, W. J., Ding, H. H. et al. (2021). Experimental study on wear properties of wheel and rail materials with different hardness values. Wear, 477, 203831. https://doi.org/10.1016/j.wear.2021.203831

- Wang, W., Huang, J., Ding, H., Wen, Z., Cui, X., Lewis, R., Liu, Q. (2024). Initiation and evolution of wheel polygonal wear: Influence of wheel-rail hardness ratios. Wear, 540-541, 205255. https://doi.org/10.1016/j.wear.2024.205255

- Zhao, H., Liu, P., Ding, Y., Jiang, B., Liu, X., Zhang, M., Chen, G. (2020). An Investigation on Wear Behavior of ER8 and SSW-Q3R Wheel Steel under Pure Rolling Condition. Metals, 10 (4), 513. https://doi.org/10.3390/met10040513

- Zhang, P., He, C., Shen, C., Dollevoet, R., Li, Z. (2024). Comprehensive validation of three-dimensional finite element modelling of wheel-rail high-frequency interaction via the V-Track test rig. Vehicle System Dynamics, 1–25. https://doi.org/10.1080/00423114.2024.2304626

- Koshel, O., Sapronova, S., Kara, S. (2023). Revealing patterns in the stressed-strained state of load-bearing structures in special rolling stock to further improve them. Eastern-European Journal of Enterprise Technologies, 4 (7 (124)), 30–42. https://doi.org/10.15587/1729-4061.2023.285894

- Fomin, O., Lovska, A., Píštěk, V., Kučera, P. (2019). Dynamic load computational modelling of containers placed on a flat wagon at railroad ferry transportation. Vibroengineering Procedia, 29, 118–123. https://doi.org/10.21595/vp.2019.21132

- Soleimani, H., Moavenian, M. (2017). Tribological Aspects of Wheel–Rail Contact: A Review of Wear Mechanisms and Effective Factors on Rolling Contact Fatigue. Urban Rail Transit, 3 (4), 227–237. https://doi.org/10.1007/s40864-017-0072-2

- Domin, R. Yu., Domin, Yu. V., Cherniak, H. Yu., Serhienko, O. V. (2022). Stiykist rukhomoho skladu vid skhodzhennia z reiok. Sievierodonetsk: Vyd-vo SNU im. V. Dalia, 232. Available at: https://dspace.snu.edu.ua/server/api/core/bitstreams/7ad0aa67-11e3-41df-ab59-2612b5848411/content

- Weilguny, R., Leitner, M., Brunnhofer, P., Pospischil, F. (2023). Investigation of dynamic gauge widening in small radius curves and its impact on lateral wheel-rail contact forces. Vehicle System Dynamics, 1–26. https://doi.org/10.1080/00423114.2023.2276762

- Djabbarov, S., Abdirakhmanov, J., Abdullaev, B., Namozov, S., Yuldoshov, R., Ergasheva, V. (2023). Rin-in comb wheels of the wheel pair of the car when moving on a curve section of the path. E3S Web of Conferences, 389, 05048. https://doi.org/10.1051/e3sconf/202338905048

- Derbiszewski, B., Obraniak, A., Wozniak, M., Rylski, A., Siczek, K., Kubiak, P. (2022). Friction Issues over the Railway Wheels-Axis Assembly Motion. Lubricants, 10 (2), 26. https://doi.org/10.3390/lubricants10020026

- Shatunov, O. V., Shvets, A. O., Kirilchuk, O. A., Shvets, A. O. (2019). Research of wheel-rail wear due to non-symmetrical loading of a flat car. Science and Transport Progress, 4 (82), 102–117. https://doi.org/10.15802/stp2019/177457

- Eadie, D. T., Elvidge, D., Oldknow, K., Stock, R., Pointner, P., Kalousek, J., Klauser, P. (2008). The effects of top of rail friction modifier on wear and rolling contact fatigue: Full-scale rail–wheel test rig evaluation, analysis and modelling. Wear, 265 (9-10), 1222–1230. https://doi.org/10.1016/j.wear.2008.02.029

- Meymand, S. Z., Keylin, A., Ahmadian, M. (2016). A survey of wheel–rail contact models for rail vehicles. Vehicle System Dynamics, 54 (3), 386–428. https://doi.org/10.1080/00423114.2015.1137956

- Golubenko, A., Sapronova, S., Tkacenko, V. (2007). Kinematics of point-to-point contact of wheels with a rails. Transport problems, 2 (3), 57–61. Available at: http://transportproblems.polsl.pl/pl/Archiwum/2007/zeszyt3/2007t2z3_07.pdf

- Agreement on use of freight wagons in international traffic (the PGV Agreement) (with amendments and additions as of 1 January 2024) (2024). Official publication OSJD Committee, Warsaw, 168. Available at: https://en.osjd.org/en/8911/page/106077?id=2858

- Mikhailov, E., Semenov, S., Sapronova, S., Tkachenko, V. (2020). On the Issue of Wheel Flange Sliding Along the Rail. Lecture Notes in Intelligent Transportation and Infrastructure, 377–385. https://doi.org/10.1007/978-3-030-38666-5_40

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Evgen Zub, Viktor Tkachenko, Svitlana Sapronova, Serhii Syvakivskiy

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.