Визначення технологічних параметрів отримання заготовок титанового сплаву ТА15 з підвищеними механічними характеристиками методом електронно-променевого 3D друку

DOI:

https://doi.org/10.15587/1729-4061.2024.306613Ключові слова:

електронно-променевий 3D друк, титановий сплав, ТА15, технологічні параметри, металографічні дослідженняАнотація

Об’єктом дослідження є процес електронно-променевого 3D друку виробів із порошку титанового сплаву ТА15. В роботі розглянуто особливості формування структури та властивостей заготовок сплаву, отриманого вказаним методом. Досліджено вплив параметрів процесу (потужності електронного пучка та геометричних параметрів сканування) на формування структури та механічних властивостей матеріалу.

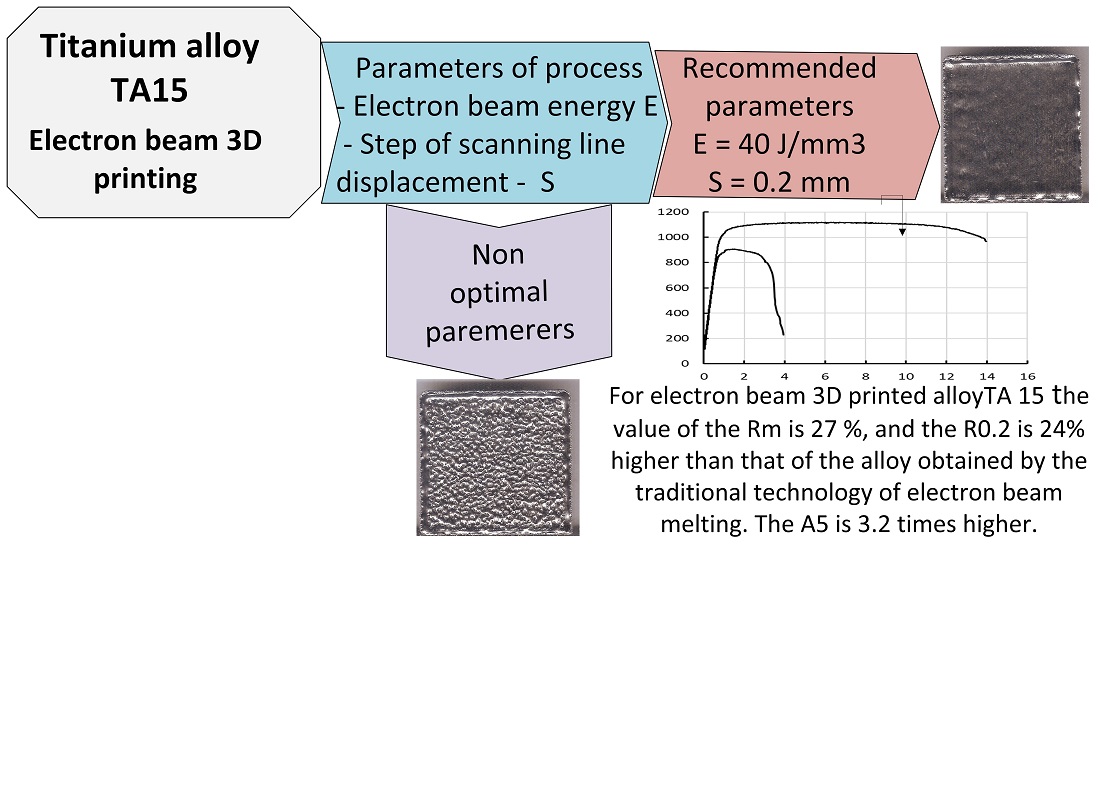

Крок зміщення траєкторії променю змінювали від 0,1 до 0,25 мм з інтервалом 0,05 мм. Питому енергію електронного променю змінювали від 20 до 70 Дж/мм3 для кожного значення кроку зміщення траєкторії.

Макроструктуру досліджували візуально, мікроструктуру вивчали методом оптичної мікроскопії. Механічні властивості визначали при випробуваннях на одновісний розтяг та ударний згин. Встановлено, що в залежності від параметрів 3D друку макроструктура більшості зразків є щільною, але при несприятливих параметрах можуть формуватися дефекти у вигляді несплавлень або вторинної усадкової пористості. Мікроструктура дендритного типу має α´+β пластинчасто-голчасту морфологію, її дисперсність та форма виділень α´-фази змінюється в залежності від параметрів процесу.

Визначено, що крок сканування 0,2 мм та енергія променю 40 Дж/мм3 дозволяє отримати дисперсну мікроструктуру матеріалу, в якому відсутні несплавлення та мікропори усадки. Значення характеристик міцності на 24 - 27 % вищі, ніж у сплаву отриманого по традиційній технології електронно променевого плавлення. Відносне подовження вище у 3,2 рази. Проте значення ударної в’язкості при несприятливій орієнтації зразка по відношенню до напрямку прикладення навантаження можуть бути нижче у порівнянні з традиційною технологією. Отримані результати можуть бути використані при розробці промислової технології 3D друку виробів з високоміцних титанових сплавів

Посилання

- Murr, L. E., Gaytan, S. M., Ramirez, D. A., Martinez, E., Hernandez, J., Amato, K. N. et al. (2012). Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. Journal of Materials Science & Technology, 28 (1), 1–14. https://doi.org/10.1016/s1005-0302(12)60016-4

- Lai, X., Yang, G., Wang, Y., Wei, Z. (2023). Heat and mass transfer in electron beam additive manufacturing. International Journal of Mechanical Sciences, 259, 108613. https://doi.org/10.1016/j.ijmecsci.2023.108613

- Shi, Y., Gong, S., Xu, H., Yang, G., Qiao, J., Wang, Z. et al. (2023). Electron beam metal additive manufacturing: Defects formation and in-process control. Journal of Manufacturing Processes, 101, 386–431. https://doi.org/10.1016/j.jmapro.2023.06.013

- Wang, X., Gong, X., Chou, K. (2015). Scanning Speed Effect on Mechanical Properties of Ti-6Al-4V Alloy Processed by Electron Beam Additive Manufacturing. Procedia Manufacturing, 1, 287–295. https://doi.org/10.1016/j.promfg.2015.09.026

- Wang, X., Chou, K. (2018). EBSD study of beam speed effects on Ti-6Al-4V alloy by powder bed electron beam additive manufacturing. Journal of Alloys and Compounds, 748, 236–244. https://doi.org/10.1016/j.jallcom.2018.03.173

- Batalha, G. F., Silva, L. C., Coelho, R. S., Teixeira, M. C. C., Castro, T. L., Pereira, M. V. S. et al. (2024). Mechanical properties characterization of Ti-6Al-4 V grade 5 (recycled) additively manufactured by selective electron beam melting (EB-PBF). Engineering Failure Analysis, 157, 107892. https://doi.org/10.1016/j.engfailanal.2023.107892

- Hrabe, N., Quinn, T. (2013). Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 1: Distance from build plate and part size. Materials Science and Engineering: A, 573, 264–270. https://doi.org/10.1016/j.msea.2013.02.064

- Hrabe, N., Quinn, T. (2013). Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Materials Science and Engineering: A, 573, 271–277. https://doi.org/10.1016/j.msea.2013.02.065

- Tamayo, J. A., Riascos, M., Vargas, C. A., Baena, L. M. (2021). Additive manufacturing of Ti6Al4V alloy via electron beam melting for the development of implants for the biomedical industry. Heliyon, 7 (5), e06892. https://doi.org/10.1016/j.heliyon.2021.e06892

- Matviichuk, V. A., Nesterenkov, V. M., Berdnikova, O. M. (2022). Additive electron beam technology of manufacture of metal products from powder materials. Avtomaticheskaya Svarka (Automatic Welding), 2022 (2), 16–25. https://doi.org/10.37434/as2022.02.03

- Matviichuk, V. A., Nesterenkov, V. M. (2020). Additive electron beam equipment for layer-by-layer manufacture of metal products from powder materials. The Paton Welding Journal, 2020 (2), 41–46. https://doi.org/10.37434/tpwj2020.02.08

- Akhonin, S., Pikulin, O., Berezos, V., Severyn, A., Erokhin, O., Kryzhanovskyi, V. (2022). Determining the structure and properties of heat-resistant titanium alloys VT3-1 and VT9 obtained by electron-beam melting. Eastern-European Journal of Enterprise Technologies, 5 (12 (119)), 6–12. https://doi.org/10.15587/1729-4061.2022.265014

- Matviichuk, V., Nesterenkov, V., Berdnikova, O. (2022). Determining the influence of technological parameters of the electron-beam surfacing process on quality indicators. Eastern-European Journal of Enterprise Technologies, 1 (12 (115)), 21–30. https://doi.org/10.15587/1729-4061.2022.253473

- Akhonin, S. V., Pikulin, O. M. (2019). Investigation of Effect of Electron Beam Surface Treatment of Titanium Alloy Ingots on Structure and Properties of Melted Metal. IOP Conference Series: Materials Science and Engineering, 582 (1), 012047. https://doi.org/10.1088/1757-899x/582/1/012047

- Matviichuk, V., Nesterenkov, V., Berdnikova, O. (2024). Determining the influence of technological parameters of electron beam surfacing process on the microstructure and microhardness of Ti-6Al-4V alloy. Eastern-European Journal of Enterprise Technologies, 1 (12 (127)), 6–12. https://doi.org/10.15587/1729-4061.2024.297773

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Serhii Akhonin, Vladimir Nesterenkov, Volodymyr Pashynskyi, Vladyslav Matviichuk, Sviatoslav Motrunich, Volodymyr Berezos, Illia Klochkov

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.