Application of QFD and FMEA methodologies for the development and improvement of an explosive ordnance disposal robot design

DOI:

https://doi.org/10.15587/1729-4061.2024.306986Keywords:

quality function deployment, failure mode and effects analysis, explosive, robotAbstract

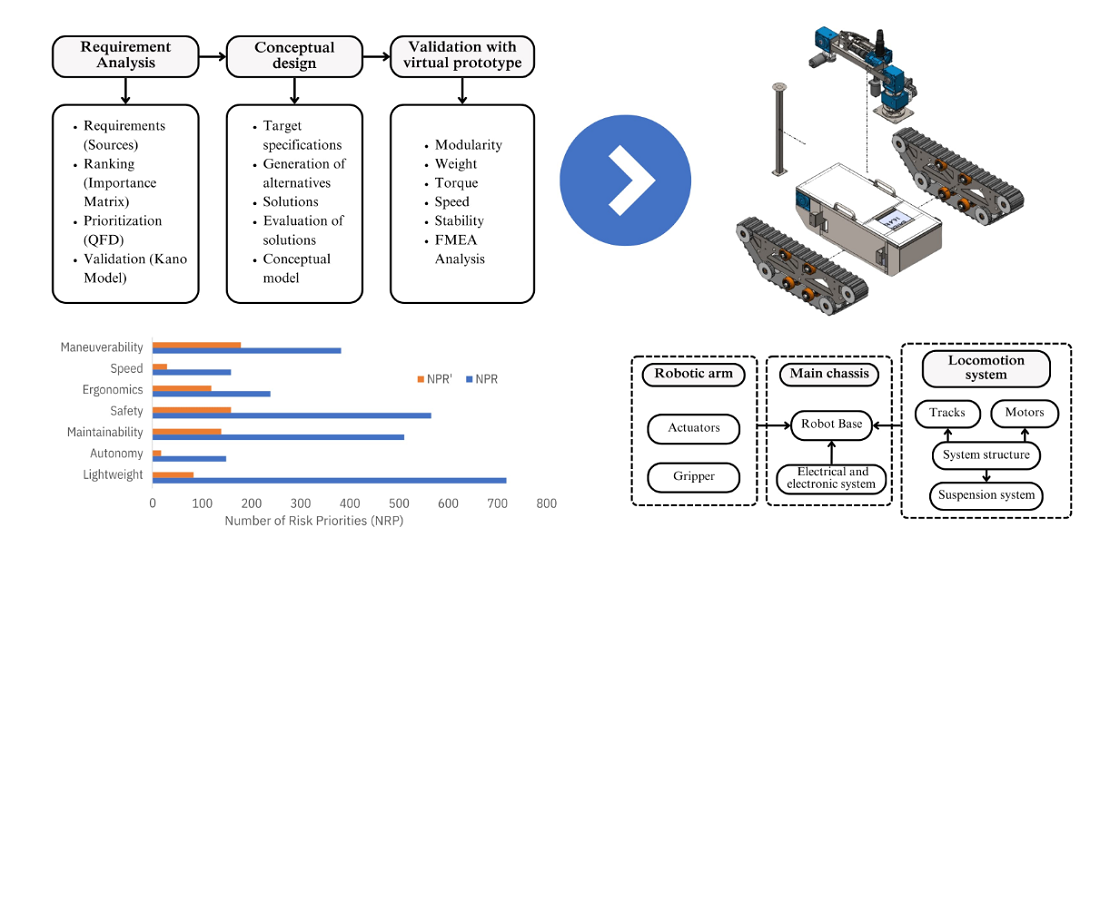

In this work, the Quality Function Deployment (QFD) and Failure Mode and Effects Analysis (FMEA) methodology based on the «Design for X» concept is studied to define the design criteria of the mechanical characteristics of an EOD robot and validated with a virtual prototype of an Explosive Ordnance Disposal (EOD) robot. The objective is the application of this methodology to obtain a product that meets the quality and reliability specifications, considering the user’s needs as input data. To validate this methodology, the technicians of the UDEX (Explosive Ordnance Disposal Unit), the mechanical characteristics of the previous version JVC 0.2 developed by the research team of the National University of San Agustin (UNSA), the minimum specifications of the robots participating in the League of Rescue Robots and the application to work in real environments were taken as a case study. The results indicate that the application of the proposed methodology has significantly improved the quality and reliability of the design. To validate the effectiveness of this methodology, a virtual prototype, called JVC 0.3, was created using SolidWorks modelling software, a significant weight reduction of 27.13 % was achieved and the operating speed was increased to 1 km/h under optimal conditions. Technical analysis of the JVC 0.3 showed significant improvements in several key areas, such as increased modularity for easier assembly and maintenance, decreased overall weight, increased torque and speed, and increased stability during operation. These factors are essential for the practical application of EOD robots in real field operations carried out by specialized units such as UDEX

Supporting Agency

- With the support of the Universidad Nacional de San Agustín de Arequipa with the following contract N◦. IBA-IB-27-2020-UNSA and UDEX-AQP

References

- Guevara Mamani, J., Pinto, P. P., Vilcapaza Goyzueta, D., Supo Colquehuanca, E., Sulla Espinoza, E., Silva Vidal, Y. (2021). Compilation and Analysis of Requirements for the Design of an Explosive Ordnance Disposal Robot Prototype Applied in UDEX-Arequipa. HCI International 2021 - Posters, 131–138. https://doi.org/10.1007/978-3-030-78642-7_18

- Czop, A., Hacker, K., Murphy, J., Zimmerman, T. (2005). Low-cost explosive ordnance disposal robot using off-the-shelf parts. Unmanned Ground Vehicle Technology VII, 5804, 130. https://doi.org/10.1117/12.602526

- Czop, A., Hacker, K., Murphy, J., Zimmerman, T. (2006). Low-cost EOD robot using off-the-shelf parts: revisions and performance testing results. Unmanned Systems Technology VIII, 6230, 62301Z. https://doi.org/10.1117/12.666531

- Szynkarczyk, P. (2005). Neutralising and assisting robot smr-100 expert – design problematics. Bulletin of the Polish Academy of Sciences: Technical Sciences, 53 (1), 87–92. Available at: https://journals.pan.pl/Content/111756/PDF/(53-1)87.pdf

- Grigore, L. Ștefăniță, Oncioiu, I., Priescu, I., Joița, D. (2021). Development and Evaluation of the Traction Characteristics of a Crawler EOD Robot. Applied Sciences, 11 (9), 3757. https://doi.org/10.3390/app11093757

- de Cubber, G., Balta, H., Lietart, C. (2014). Teodor: A Semi-Autonomous Search and Rescue and Demining Robot. Applied Mechanics and Materials, 658, 599–605. https://doi.org/10.4028/www.scientific.net/amm.658.599

- Ștefan, A., Grigore, L. Ștefăniță, Oncioiu, I., Constantin, D., Mustață et al. (2022). Influence of the Stiffness of the Robotic Arm on the Position of the Effector of an EOD Robot. Electronics, 11 (15), 2355. https://doi.org/10.3390/electronics11152355

- Silva Vidal, Y., Elvis Supo, C., Milton Ccallata, C., Jesus Mamani, G., Betancur P., M., Brunno Pino, C. et al. (2022). Analysis and Evaluation of a EOD Robot Prototype. 2022 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), 1–6. https://doi.org/10.1109/iemtronics55184.2022.9795740

- Fargnoli, M., Sakao, T. (2016). Uncovering differences and similarities among quality function deployment-based methods in Design for X: Benchmarking in different domains. Quality Engineering, 29 (4), 690–712. https://doi.org/10.1080/08982112.2016.1253849

- Atilano, L., Martinho, A., Silva, M. A., Baptista, A. J. (2019). Lean Design-for-X: Case study of a new design framework applied to an adaptive robot gripper development process. Procedia CIRP, 84, 667–672. https://doi.org/10.1016/j.procir.2019.04.190

- Furtado, L. F. F., Villani, E., Trabasso, L. G., Silva, C. E. O. (2013). DTW: a design method for designing robot end-effectors. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 36 (4), 871–885. https://doi.org/10.1007/s40430-013-0109-8

- Gonçalves-Coelho, A. M., Mourão, A. J. F. (2007). Axiomatic design as support for decision-making in a design for manufacturing context: A case study. International Journal of Production Economics, 109 (1-2), 81–89. https://doi.org/10.1016/j.ijpe.2006.11.002

- Würtenberger, J., Kloberdanz, H., Lotz, J., von Ahsen, A. (2014). Application of the FMEA during the product development process – Dependencies between level of information and quality of result. Design Methods, 417–426.

- Yang, Z., Kou, M. (2021). Innovation fusion design of mechanical system robust design. The International Journal of Advanced Manufacturing Technology, 124 (11-12), 3795–3811. https://doi.org/10.1007/s00170-021-07843-4

- Munoz, V. F., Garcia-Morales, L., Fernandez-Lozano, J., Gomez-De-Gabriel, J. M., Garcia-Cerezo, A., Vara, C. (2004). Risk analysis for fail-safe motion control implementation in surgical robotics. Proceedings World Automation Congress, 235–240.

- Backar, S. (2019). Integrative Framework of Kansei Engineering (KE) and Kano Model (KM) applied to Light Bulb Changer. The Academic Research Community Publication, 2 (4), 430–439. https://doi.org/10.21625/archive.v2i4.392

- Korayem, M. H., Iravani, A. (2008). Improvement of 3P and 6R mechanical robots reliability and quality applying FMEA and QFD approaches. Robotics and Computer-Integrated Manufacturing, 24 (3), 472–487. https://doi.org/10.1016/j.rcim.2007.05.003

- Shvetsova, O. A., Park, S. C., Lee, J. H. (2021). Application of Quality Function Deployment for Product Design Concept Selection. Applied Sciences, 11 (6), 2681. https://doi.org/10.3390/app11062681

- Büyüközkan, G., Ilıcak, Ö., Feyzioğlu, O. (2021). An Integrated QFD Approach for Industrial Robot Selection. Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, 561–570. https://doi.org/10.1007/978-3-030-85906-0_61

- Sørensen, C. G., Jørgensen, R. N., Maagaard, J., Bertelsen, K. K., Dalgaard, L., Nørremark, M. (2010). Conceptual and user-centric design guidelines for a plant nursing robot. Biosystems Engineering, 105 (1), 119–129. https://doi.org/10.1016/j.biosystemseng.2009.10.002

- Li, M., Zhang, A. (2022). Innovative design of intelligent medical delivery robot based on FAHP and QFD. ICETIS 2022; 7th International Conference on Electronic Technology and Information Science.

- Pasawang, T., Chatchanayuenyong, T., Sa-Ngiamvibool, W. (2015). QFD-based conceptual design of an autonomous underwater robot. Songklanakarin Journal of Science and Technology, 37 (6), 659–668. Available at: https://www.thaiscience.info/journals/Article/SONG/10977690.pdf

- Jiménez, G. E. C., Cárdenas, D. J. M., Aponte, J. A., Sánchez, O. F. A., Monroy, M. F. M. (2017). QFD design methology and construction of a type rover mobile robotic platform. ARPN Journal of Engineering and Applied Sciences, 12 (4), 1098–1104. Available at: http://www.arpnjournals.org/jeas/research_papers/rp_2017/jeas_0217_5731.pdf

- Kobayashi, H., Shimizu, R., Takeuchi, K., Sugai, R., Hasegawa, H. (2022). RoboCup Rescue 2022 Team Description Paper Nexis-R. RoboCup Rescue 2022. Available at: https://tdp.robocup.org/wp-content/uploads/tdp/robocup/2022/robocuprescue-robot/nexis-r-355/robocup-2022-robocuprescue-robot-nexis-riU2awoV6f5.pdf

- Morimoto, Y., Tomiyama, T., Michikawa, R. (2022). RoboCup Rescue 2022 Team Description Paper SHINOBI. ROBOCUP RESCUE 2022. Available at: https://tdp.robocup.org/wp-content/uploads/tdp/robocup/2022/robocuprescue-robot/shinobi-356/robocup-2022-robocuprescue-robot-shinobiAw37ofmjWF.pdf

- Karmaker, C. L., Halder, P., Ahmed, S. M. T. (2019). Customer driven quality improvement of a specific product through AHP and entropy based QFD: a case study. International Journal of the Analytic Hierarchy Process, 11 (3), 389–414. https://doi.org/10.13033/ijahp.v11i3.606

- Mamani G., J., Ccallata C., M., Flores, E. V., Meneses, D., Betancur, M. A., Silva, Y. L., Apaza, J. L. (2024). Development of an EOD Robot for the Arequipa Explosive Disposal Unit. International Journal of Mechanical Engineering and Robotics Research, 13 (4), 414–427. https://doi.org/10.18178/ijmerr.13.4.414-427

- Vilcapaza Goyzueta, D., Guevara Mamani, J., Sulla Espinoza, E., Supo Colquehuanca, E., Silva Vidal, Y., Pinto, P. P. (2021). Evaluation of a NUI Interface for an Explosives Deactivator Robotic Arm to Improve the User Experience. HCI International 2021 - Late Breaking Posters, 288–293. https://doi.org/10.1007/978-3-030-90176-9_37

- Montoya Angulo, A., Pari Pinto, L., Sulla Espinoza, E., Silva Vidal, Y., Supo Colquehuanca, E. (2022). Assisted Operation of a Robotic Arm Based on Stereo Vision for Positioning near an Explosive Device. Robotics, 11 (5), 100. https://doi.org/10.3390/robotics11050100

- Andres, M. A., Pari, L., Elvis, S. C. (2021). Design of a User Interface to Estimate Distance of Moving Explosive Devices with Stereo Cameras. 2021 6th International Conference on Image, Vision and Computing (ICIVC), 362–366. https://doi.org/10.1109/icivc52351.2021.9526934

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Brayan Alex Apfata Limachi, Frank Alexander Cari Mora, Yuri Saúl Sivincha Quispe, Erick Valdeiglesias Flores, Yuri Lester Silva Vidal, Erasmo Sulla Espinoza, Lizardo Pari

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.