Improvement of wear-resistant and thermal conductivity of aluminum matrix composite reinforced AL2O3/SiCw/Mg powder

DOI:

https://doi.org/10.15587/1729-4061.2024.308704Keywords:

aluminum hybrid composite, powder metallurgy hybrid Al2O3, SiCw/Mg, thermal conductivity, wear resistanceAbstract

Technological progress demands the development of materials that have special characteristics such as high strength, stiffness, light weight, and good thermal conductivity at a low price. The development of hybrid metal matrix composites is the most important field in advanced materials science engineering.

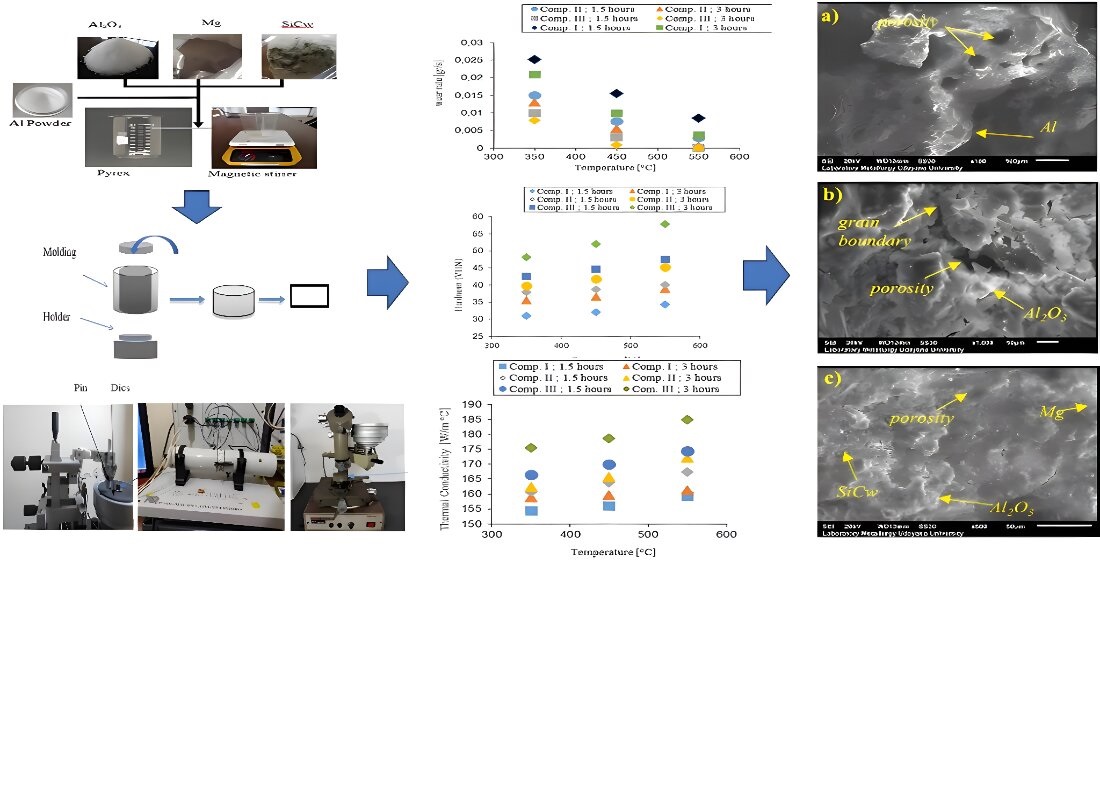

This research determines about aluminum matrix composites (AMC) reinforced with alumina (Al2O3), Silicon carbide whisker (SiCw), and magnesium (Mg) addition. The matrix is made of 90 % pure aluminum powder, and commercially available reinforcing materials include Al2O3, SiCw, and Mg. Objectives include variation of reinforcement fraction and matrix, sintering holding temperature and time. The selection of the sample making process using powder technology followed by the sintering process at different temperatures namely 350, 450 and 550 °C with variations in holding time of 1, 2 and 3 hours. The purpose of this study was to determine the effect of variations in the fraction of reinforcement and sintering treatment on the properties of wear resistance, hardness and thermal conductivity of aluminum matrix composites.

The results showed that the composition ratio of reinforcement to aluminum in sintering treatment significantly affected the mechanical properties. The wear resistance of the material shows excellent performance, namely wear resistance of 0.000065 gr/s, hardness of 45.234 VHN and thermal conductivity of 184.855 Watt/m °C, at a reinforcement composition combination of 10 %AL2O3, 10 %SiCw and 20 %Mg and a sintering temperature of 550 °C. This indicates that the Aluminum matrix composite reinforced with Al2O3/(SiCw/Mg) is able to support the friction load due to its low wear rate, good hardness, and good thermal conductivity. This material is very suitable to be used as tribology material, brake element, especially brake drum

References

- Gu, H., Liu, C., Zhu, J., Gu, J., Wujcik, E. K., Shao, L. et al. (2017). Introducing advanced composites and hybrid materials. Advanced Composites and Hybrid Materials, 1 (1), 1–5. https://doi.org/10.1007/s42114-017-0017-y

- Jayakrishnan, S., Ragul, G. (2016). Effect of Mechanical Properties of Composite Material Under The Influence of Different Commercial Oils. IJIRT, 2 (8), 60–66. Available at: https://www.researchgate.net/publication/323135098_EFFECT_OF_MECHANICAL_PROPERTIES_OF_COMPOSITE_MATERIAL_UNDER_THE_INFLUENCE_OF_DIFFERENT_COMMERCIAL_OILS

- Koli, D. K., Agnihotri, G., Purohit, R. (2015). Advanced Aluminium Matrix Composites: The Critical Need of Automotive and Aerospace Engineering Fields. Materials Today: Proceedings, 2 (4-5), 3032–3041. https://doi.org/10.1016/j.matpr.2015.07.290

- Chintada, S., Dora, S. P., Kare, D. (2021). Mechanical Behavior and Metallographic Characterization of Microwave Sintered Al/SiC Composite Materials – an Experimental Approach. Silicon, 14 (12), 7341–7352. https://doi.org/10.1007/s12633-021-01409-5

- Kanth, U. R., Rao, P. S., Krishna, M. G. (2019). Mechanical behaviour of fly ash/SiC particles reinforced Al-Zn alloy-based metal matrix composites fabricated by stir casting method. Journal of Materials Research and Technology, 8 (1), 737–744. https://doi.org/10.1016/j.jmrt.2018.06.003

- Bharathi, P., Kumar, T. S. (2023). Mechanical Characteristics and Wear Behaviour of Al/SiC and Al/SiC/B4C Hybrid Metal Matrix Composites Fabricated Through Powder Metallurgy Route. Silicon, 15 (10), 4259–4275. https://doi.org/10.1007/s12633-023-02347-0

- Sarvani, R. K., Mohinoddin, M., Ramakrishna, L. S. (2024). Characterization and Mechanical Testing of Hybrid Metal Composites of Aluminium Alloy (A356/LM25) Reinforced by Micro-Sized Ceramic Particles. Journal of The Institution of Engineers (India): Series C, 105 (3), 457–470. https://doi.org/10.1007/s40032-024-01064-w

- Vencl, A., Bobic, I., Arostegui, S., Bobic, B., Marinković, A., Babić, M. (2010). Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC+graphite particles. Journal of Alloys and Compounds, 506 (2), 631–639. https://doi.org/10.1016/j.jallcom.2010.07.028

- Chechi, P., Maurya, S. K., Prasad, R., Manna, A. (2023). Influence on Microstructural and Mechanical Properties of Al2O3/Graphite/Flyash-Reinforced Hybrid Composite Using Scrap Aluminum Alloy. International Journal of Metalcasting, 18 (2), 975–986. https://doi.org/10.1007/s40962-023-01069-8

- Srivastava, S., Sarangi, S. K., Singh, S. P. (2024). Water Absorptivity and Porosity Investigation of Nano Bio-silica, Hemp, and Bamboo Fibre-reinforced Chitosan Bio-composite Material. Silicon, 16 (11), 4723–4728. https://doi.org/10.1007/s12633-024-03027-3

- Standard Test Method for Thermal Conductivity of Solids by Means of the Guarded-Comparative-Longitudinal Heat Flow Technique. ASTM International.

- Agus Suryawan, I. G. P., Suardana, N. P. G., Winaya, I. N. S., Suyasa, I. W. B. (2020). A study on correlation between hardness and thermal conductivity of polymer composites reinforced with stinging nettle fiber. International Journal of Civil Engineering and Technology (IJCIET), 11 (1). https://doi.org/10.34218/ijciet.11.1.2020.010

- Vishwakarma, R. K., Pal, S. K., Chakladar, N. D. (2024). Effect of Carbon Fibre Reinforcement on an Aluminium Metal Matrix Composite Joint Through Upward Friction Stir Processing. Metals and Materials International. https://doi.org/10.1007/s12540-024-01690-0

- Chakrapani, P., Suryakumari, T. S. A. (2021). Mechanical properties of aluminium metal matrix composites-A review. Materials Today: Proceedings, 45, 5960–5964. https://doi.org/10.1016/j.matpr.2020.09.247

- Surappa, M. K., Prasad, S. V., Rohatgi, P. K. (1982). Wear and abrasion of cast Al-Alumina particle composites. Wear, 77 (3), 295–302. https://doi.org/10.1016/0043-1648(82)90055-2

- Manohar, G., Pandey, K. M., Maity, S. R. (2022). Effect of Variations in Microwave Processing Temperatures on Microstructural and Mechanical Properties of AA7075/SiC/Graphite Hybrid Composite Fabricated by Powder Metallurgy Techniques. Silicon, 14 (13), 7831–7847. https://doi.org/10.1007/s12633-021-01554-x

- Siddesh Kumar, N. M. (2022). Effect on wear property of aluminium metal matrix composite reinforced with different solid lubricants: a review. International Journal of System Assurance Engineering and Management, 14 (S4), 909–917. https://doi.org/10.1007/s13198-022-01654-w

- Mazahery, A., Abdizadeh, H., Baharvandi, H. R. (2009). Development of high-performance A356/nano-Al2O3 composites. Materials Science and Engineering: A, 518 (1-2), 61–64. https://doi.org/10.1016/j.msea.2009.04.014

- Xue, C., Yu, J. K., Zhu, X. M. (2011). Thermal properties of diamond/SiC/Al composites with high volume fractions. Materials & Design, 32 (8-9), 4225–4229. https://doi.org/10.1016/j.matdes.2011.04.032

- Ashwath, P., Xavior, M. A. (2016). Processing methods and property evaluation of Al2O3 and SiC reinforced metal matrix composites based on aluminium 2xxx alloys. Journal of Materials Research, 31 (9), 1201–1219. https://doi.org/10.1557/jmr.2016.131

- Suarsana, K., Soenoko, R. (2015). Hardness, Density and Porosity of Al/(SiCw+Al2O3p) Composite by Powder Metallurgy Process without and with Sintering. Applied Mechanics and Materials, 776, 246–252. https://doi.org/10.4028/www.scientific.net/amm.776.246

- Chak, V., Chattopadhyay, H., Dora, T. L. (2020). A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. Journal of Manufacturing Processes, 56, 1059–1074. https://doi.org/10.1016/j.jmapro.2020.05.042

- Singh, N. K., Sethuraman, B. (2023). Development and Characterization of Aluminium AA7075 Hybrid Composite Foams (AHCFs) Using SiC and TiB2 Reinforcement. International Journal of Metalcasting, 18 (1), 212–227. https://doi.org/10.1007/s40962-023-01009-6

- Corrochano, J., Cerecedo, C., Valcárcel, V., Lieblich, M., Guitián, F. (2008). Whiskers of Al2O3 as reinforcement of a powder metallurgical 6061 aluminium matrix composite. Materials Letters, 62 (1), 103–105. https://doi.org/10.1016/j.matlet.2007.04.080

- Lakra, S., Bandyopadhyay, T. K., Das, S., Das, K. (2021). Thermal conductivity of in-situ dual matrix aluminum composites with segregated morphology. Materials Research Bulletin, 144, 111515. https://doi.org/10.1016/j.materresbull.2021.111515

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 I. K. G. Sugita, K. Suarsna, N. P. G. Suardana, Rudi Sunoko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.