Determining the efficiency of techniques for optimizing the number of tags in modern human-machine interfaces under conditions of limited resources

DOI:

https://doi.org/10.15587/1729-4061.2024.309029Keywords:

human machine interface, tag, resource optimization, tag licensingAbstract

The object of this study is modern Human-Machine Interfaces (HMI) and SCADA systems in the industry. The subject of research is techniques for optimizing the number of tags (variables) in the SCADA/HMI environment to enhance resource utilization efficiency.

One of the challenges in creating SCADA/HMI-based solutions can be the number of tags (variables) in the runtime environment. A large number of tags can lead to a problem of limited available resources.

The technique presented here allow for the optimization of the number of tags used in Human-Machine Interface systems built with SCADA software and operator panels in combination with Programmable Logic Controllers (PLCs).

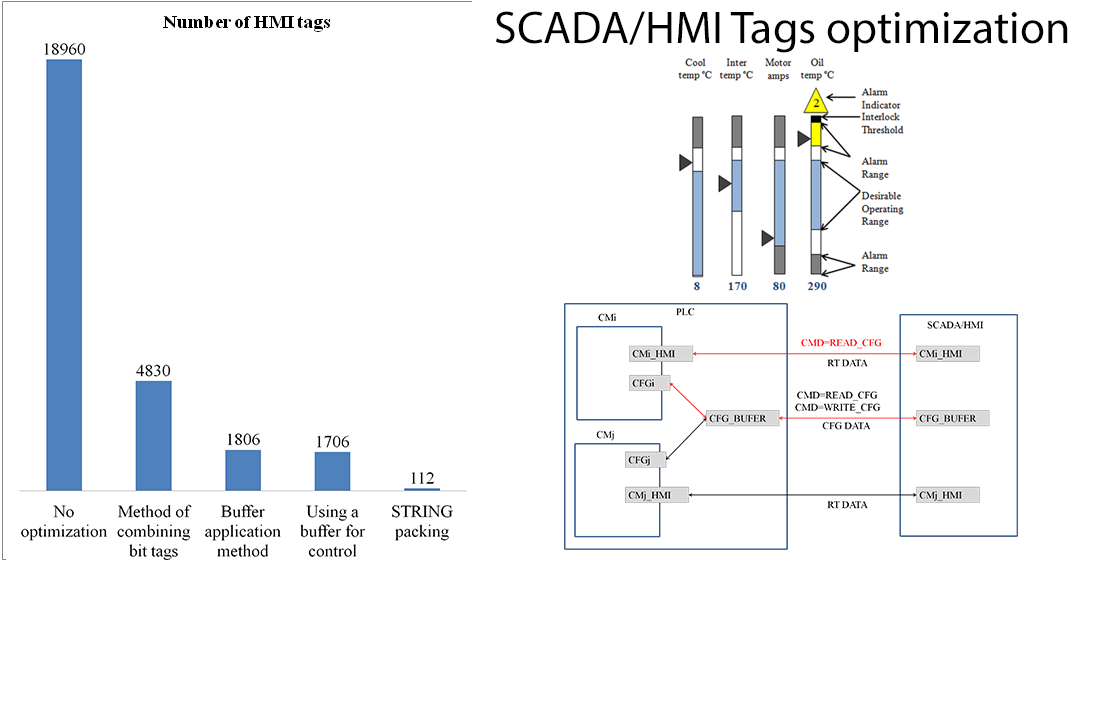

An evaluation of the efficiency of techniques for reducing the number of HMI tags was conducted on an experimental configuration consisting of objects such as discrete input/output, analog input/output, actuators such as valves with discrete/analog control, and drives with frequency converters. The optimization coefficient, defined as the ratio of the number of input/output tags used directly to the number of tags after applying the optimization principle, was used as the efficiency criterion. Depending on the techniques and their combinations, the criterion values reached orders of 4, 10, and in one case even more than 100. These values are explained by the application of multiplexing approaches and various packing techniques.

The advantages and disadvantages of the reported techniques, as well as their application limitations, have been identified. Some techniques are suitable only for specific tasks.

These techniques could be applied in practical implementation when designing modern high-efficiency Human-Machine Interfaces under conditions of limited resources.

References

- Pupena, O. M. (2020). Rozroblennia liudyno-mashynnykh interfeisiv ta system zbyrannia danykh z vykorystanniam prohramnykh zasobiv SCADA/HMI. Kyiv: LIRA-K, 594. Available at: https://lira-k.com.ua/preview/12760.pdf

- Shyshak, A., Pupena, O. (2020). Management of human-machine interface lifecycle. Scientific Works of National University of Food Technologies, 26 (3), 17–27. https://doi.org/10.24263/2225-2924-2020-26-3-4

- Urbas, L., Obst, M., Stöss, M. (2012). Formal Models for High Performance HMI Engineering. IFAC Proceedings Volumes, 45 (2), 854–859. https://doi.org/10.3182/20120215-3-at-3016.00151

- Panter, L., Leder, R., Keiser, D., Freitag, M. (2024). Requirements for Human-Machine-Interaction Applications in Production and Logistics within Industry 5.0 – A Case Study Approach. Procedia Computer Science, 232, 1164–1171. https://doi.org/10.1016/j.procs.2024.01.114

- Crompton, J. (2021). Data management from the DCS to the historian and HMI. Machine Learning and Data Science in the Power Generation Industry, 93–122. https://doi.org/10.1016/b978-0-12-819742-4.00005-6

- Šverko, M., Grbac, T. G. (2024). Automated HMI design as a custom feature in industrial SCADA systems. Procedia Computer Science, 232, 1789–1798. https://doi.org/10.1016/j.procs.2024.02.001

- Scaife, R. (2016). Control system interface design. Human Factors in the Chemical and Process Industries, 223–239. https://doi.org/10.1016/b978-0-12-803806-2.00013-3

- Mustafa, F. E., Ahmed, I., Basit, A., Alvi, U.-E.-H., Malik, S. H., Mahmood, A., Ali, P. R. (2023). A review on effective alarm management systems for industrial process control: Barriers and opportunities. International Journal of Critical Infrastructure Protection, 41, 100599. https://doi.org/10.1016/j.ijcip.2023.100599

- Rao, H. R. M., Zhou, B., Brown, K., Chen, T., Shah, S. L. (2024). Alarm correlation analysis with applications to industrial alarm management. Control Engineering Practice, 143, 105812. https://doi.org/10.1016/j.conengprac.2023.105812

- Cruz-Benito, J., García-Peñalvo, F. J., Therón, R. (2019). Analyzing the software architectures supporting HCI/HMI processes through a systematic review of the literature. Telematics and Informatics, 38, 118–132. https://doi.org/10.1016/j.tele.2018.09.006

- Zhou, C., Su, H., Tang, X., Cao, Y., Yang, S. (2024). Global self-optimizing control of batch processes. Journal of Process Control, 135, 103163. https://doi.org/10.1016/j.jprocont.2024.103163

- Pupena, O., Mirkevych, R., Klymenko, O. (2020). Praktychni rekomendatsiyi do realizatsiyi elementiv standartu IEC 61512 v prohramnomu zabezpechenni system keruvannia. TEKhNIChNYI KOMITET 185 «PROMYSLOVA AVTOMATYZATsIIa». Kyiv. Available at: https://tk185.appau.org.ua/guide/aCampus-users-guides-IEC61512+++.pdf

- Pupena, O., Klymenko, O., Mirkevych, R. (2020). Pryntsypy funktsionuvannia system keruvannia osnovnym vyrobnytstvom cherez pryzmu standartu IEC-62264. TEKhNIChNYI KOMITET 185 «PROMYSLOVA AVTOMATYZATsIIa». Kyiv. Available at: https://tk185.appau.org.ua/guide/aCampus-users-guides-IEC62264+++.pdf

- Rockwell Automation Process HMI Style Guide. White Paper. Rockwell Automation. Available at: https://literature.rockwellautomation.com/idc/groups/literature/documents/wp/proces-wp023_-en-p.pdf

- Best Design Practices: How to Create High Performance HMI to Enhance Operator Efficiency (2023). White Paper. Movicon.NExT. Available at: https://www.tug.at/images/news/whitepapers/Best_practices_for_high_performance_HMI_design_White_Paper_ENUS_2023-03-24.pdf

- PAC Framework V1. Available at: https://github.com/pupenasan/PACFramework

- Bhole, M., Kastner, W., Sauter, T. (2023). Knowledge Representation of Asset Information and Performance in OT Environments. 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA). https://doi.org/10.1109/etfa54631.2023.10275721

- Peco Chacón, A. M., García Márquez, F. P. (2019). False Alarms Management by Data Science. Data Science and Digital Business, 301–316. https://doi.org/10.1007/978-3-319-95651-0_15

- Peco Chacón, A. M., García Márquez, F. P. (2021). False Alarm Detection in Wind Turbine Management by Tree Model. Lecture Notes on Data Engineering and Communications Technologies, 543–553. https://doi.org/10.1007/978-3-030-79203-9_42

- Qiu, Y., Feng, Y., Infield, D. (2020). Fault diagnosis of wind turbine with SCADA alarms based multidimensional information processing method. Renewable Energy, 145, 1923–1931. https://doi.org/10.1016/j.renene.2019.07.110

- Asaadi, M., Izadi, I., Hassanzadeh, A., Yang, F. (2022). Assessment of alarm systems for mixture processes and intermittent faults. Journal of Process Control, 114, 120–130. https://doi.org/10.1016/j.jprocont.2022.04.002

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Volodymyr Polupan, Roman Mirkevych, Oleksandr Pupena, Oleh Klymenko, Oleksii Mirkevych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.