Determining of the effect of reinforcing microrelief guides on the efficiency of folding integrated covers

DOI:

https://doi.org/10.15587/1729-4061.2024.309481Keywords:

integrated covers, optimal parameters of pulsed laser radiation, strengthening of folding strips, microrelief guides, microstructural changes in the materialAbstract

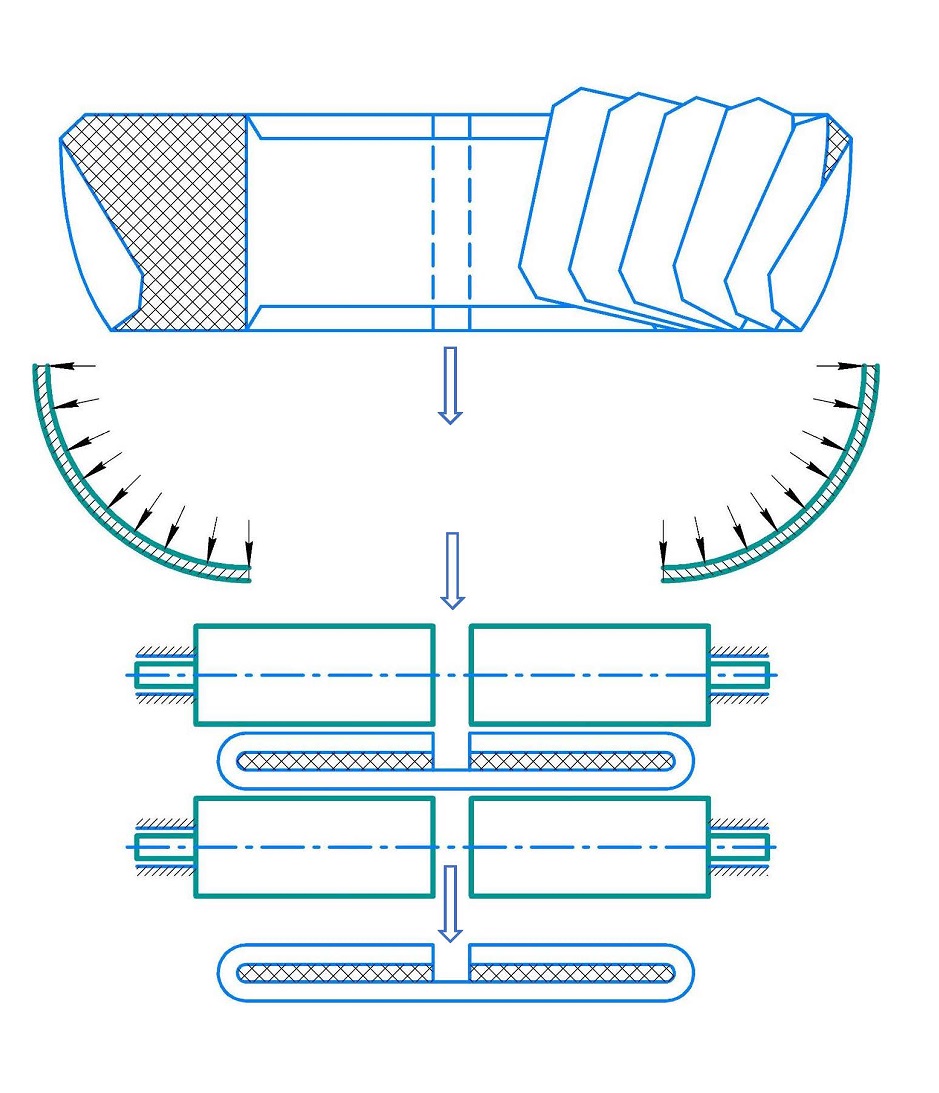

The object of research is the processes of strengthening the working surfaces of profile folding strips made of stainless steel AISI 347 and carbon steel AISI 1005 using laser formation of microrelief guides. The analytical and experimental studies are based on the technique of laser microrelief formation by pulsed laser effects. The main assumption of the study is that the use of laser microrelief formation could increase the hardness and wear resistance of the folding strips, improving the process of folding integrated covers. Analyzing the effect of different hardening methods on the mechanical properties and wear resistance of the working surfaces of folding strips is necessary to achieve this goal. A methodology for assessing microstructural changes and their impact on the mechanical properties of folding strips during laser hardening has been proposed. It has been shown that the formation of microrelief guides by laser pulse exposure reduces the thermal load on the material, increases the uniformity of hardening and wear resistance. The revealed wear rates calculated for carbon steel AISI 1005 are 0.875, and for stainless steel AISI 347 – 0.345. To improve the accuracy and efficiency of the folding process, a methodology has been devised for calculating the quantitative formation of microrelief guides on the working surface of profile folding strips. This will not only improve the wear resistance and mechanical properties of the strips but also optimize production processes. Differences in the results of hardening for stainless steel AISI 347 and carbon steel AISI 1005 were found: the hardness values for AISI 347 are 3,088–4,904 MPa at a load of 50–350 g with a deviation of 37.1 %, and for AISI 1005 – 2141–1665 MPa with a deviation of 22.3 %

References

- Kyrychok, P., Paliukh, D. (2024). Research on the Impact of Profile Geometry and Microrelief Hardening on the Wear Resistance of Folding Plates. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 1 (83), 4–17. https://doi.org/10.20535/2077-7264.1(83).2024.305494

- Cao, X., Wu, J., Zhong, G., Wu, J., Chen, X. (2024). Laser Shock Peening: Fundamentals and Mechanisms of Metallic Material Wear Resistance Improvement. Materials, 17 (4), 909. https://doi.org/10.3390/ma17040909

- Li, X., Zhou, L., Zhao, T., Pan, X., Liu, P. (2022). Research on Wear Resistance of AISI 9310 Steel with Micro-Laser Shock Peening. Metals, 12 (12), 2157. https://doi.org/10.3390/met12122157

- Praveenkumar, K., Swaroop, S., Manivasagam, G. (2022). Effect of multiple laser peening on microstructural, fatigue and fretting-wear behaviour of austenitic stainless steel. Surface and Coatings Technology, 443, 128611. https://doi.org/10.1016/j.surfcoat.2022.128611

- Lesyk, D. A., Martinez, S., Mordyuk, B. N., Dzhemelinskyi, V. V., Lamikiz, А., Prokopenko, G. I. et al. (2020). Combining laser transformation hardening and ultrasonic impact strain hardening for enhanced wear resistance of AISI 1045 steel. Wear, 462-463, 203494. https://doi.org/10.1016/j.wear.2020.203494

- Wang, C., Li, R., Bi, X., Yuan, W., Gu, J., Chen, J. et al. (2023). Microstructure and wear resistance property of laser cladded CrCoNi coatings assisted by ultrasonic impact treatment. Journal of Materials Research and Technology, 22, 853–864. https://doi.org/10.1016/j.jmrt.2022.11.170

- Karamimoghadam, M., Rezayat, M., Moradi, M., Mateo, A., Casalino, G. (2024). Laser Surface Transformation Hardening for Automotive Metals: Recent Progress. Metals, 14 (3), 339. https://doi.org/10.3390/met14030339

- Niketh, S., Samuel, G. L. (2019). Hybrid Micro Textures – A Multi-Scale Surface Engineering Approach For Enhancing Tribological Characteristics. Journal of Laser Micro/Nanoengineering, 14 (3). https://doi.org/10.2961/jlmn.2019.03.0006

- Yuan, S., Lin, N., Wang, W., Zhang, H., Liu, Z., Yu, Y. et al. (2022). Correlation between surface textural parameter and tribological behaviour of four metal materials with laser surface texturing (LST). Applied Surface Science, 583, 152410. https://doi.org/10.1016/j.apsusc.2021.152410

- Karamimoghadam, M., Moradi, M., Azami, M. (2022). A comparative investigation of different overlaps of the diode laser hardening in low-carbon steel and stainless steel. Optik, 251, 168093. https://doi.org/10.1016/j.ijleo.2021.168093

- Masood Arif Bukhari, S., Husnain, N., Arsalan Siddiqui, F., Tuoqeer Anwar, M., Abbas Khosa, A., Imran, M. et al. (2023). Effect of laser surface remelting on Microstructure, mechanical properties and tribological properties of metals and alloys: A review. Optics & Laser Technology, 165, 109588. https://doi.org/10.1016/j.optlastec.2023.109588

- Kandavalli, S. R., Rao, G. B., Bannaravuri, P. K., Rajam, M. M. K., Kandavalli, S. R., Ruban, S. R. (2021). Surface strengthening of aluminium alloys/composites by laser applications: A comprehensive review. Materials Today: Proceedings, 47, 6919–6925. https://doi.org/10.1016/j.matpr.2021.05.191

- Zheng, X., Song, H., Zhang, Q., Ye, X., Meng, L., Tan, J. (2017). Effect of Laser Surface Texturing on Tribological Properties of Materials: a Review. https://doi.org/10.11896/j.issn.1005-023X.2017.017.010

- Archard, J. F. (1953). Contact and Rubbing of Flat Surfaces. Journal of Applied Physics, 24 (8), 981–988. https://doi.org/10.1063/1.1721448

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Petro Kyrychok, Dmytro Paliukh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.