Визначення закономірностей сепарації рушанки насіння конопель

DOI:

https://doi.org/10.15587/1729-4061.2024.309869Ключові слова:

насіння конопель, обрушування насіння, ядро насіння, сепарація рушанки, розділення за розміром, очищення, аспіраційна колонкаАнотація

Об’єктом дослідження є технологічні процеси сепарації, рушанка насіння промислових конопель, аспіраційна колонка, цілі ядра.

Проблемою, що вирішувалася, було визначення техніко-технологічних рішень, які уможливлять інтенсифікацію виробничих процесів сепарації рушанки насіння промислових конопель.

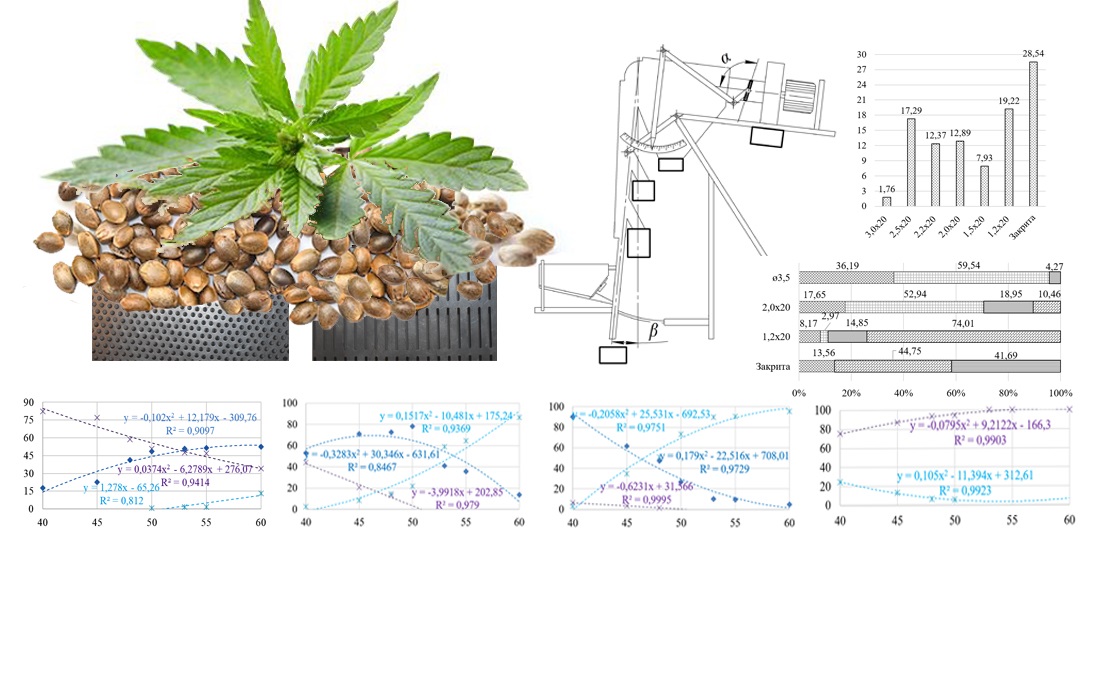

Досліджено сепарацію рушанки насіння конопель за лінійними розмірами на решетах із круглими та довгастими отворами.

Встановлений відсоток затриманої рушанки решіт з отворами круглої форми ø3,5 мм складав – 25,98 %, ø3,0 мм – 23,59 %, ø2,0 мм – 40,28 %, відповідно. Решета ø3,5 та ø2,0 мм уможливили отримати фракції рушанки з двома компонентами умовно різними за співвідношенням «маса-розмір».

Використання решіт з отворами довгастої форми уможливило одержати фракції, що складалися мінімум з трьох компонентів. Решета з робочими отворами довгастої форми 3,0×20 мм, через низьку (1,76 %) спроможність затримувати складові рушанки насіння конопель, малоефективні.

Засміченість ядер рушанки, розділеної за лінійними розмірами на комбінованих решетах із отворами круглої та довгастої форм, складала: варіант сепарації №1 – 48,70 %, варіант №2 – 45,74 %, варіант №3 – 60,25 %, варіант №4 – 49,32 %, відповідно.

Встановлено, що використання аспіраційної колонки уможливило видалити з рушанки до 32,1 % засміченості у вигляді легкої фракції. Застосування аспіраційної колонки уможливило зменшити вміст насіннєвої оболонки у варіанті сепарації №1 – 3,0–5,7 рази, варіанті №2 –1,35–3,7 рази, варіанті №3 – 1,9–11,2рази, варіант №4 – 1,5–4,8 рази, відповідно.

Кількісний та компонентний склад фракцій рушанки, отриманих за умов використання аспіраційної колонки з встановленими раціональними значеннями кута відкриття повітряної заслінки α=53° та кута вертикального нахилу повітряного каналу β=6°, склав: ступінь І – «важка» фракція – 51,78 %, 27,56 % відходи, до 20 % «легка» фракція ІІ та ІІІ ступені

Посилання

- Schultz, C. J., Lim, W. L., Khor, S. F., Neumann, K. A., Schulz, J. M., Ansari, O. et al. (2020). Consumer and health-related traits of seed from selected commercial and breeding lines of industrial hemp, Cannabis sativa L. Journal of Agriculture and Food Research, 2, 100025. https://doi.org/10.1016/j.jafr.2020.100025

- Alonso-Esteban, J. I., Pinela, J., Ćirić, A., Calhelha, R. C., Soković, M., Ferreira, I. C. F. R. et al. (2022). Chemical composition and biological activities of whole and dehulled hemp (Cannabis sativa L.) seeds. Food Chemistry, 374, 131754. https://doi.org/10.1016/j.foodchem.2021.131754

- Sheichenko, V., Petrachenko, D., Koropchenko, S., Rogovskii, I., Gorbenko, O., Volianskyi, M., Sheichenko, D. (2024). Substantiating the rational parameters and operation modes for the hemp seed centrifugal dehuller. Engineering Technological Systems, 2 (1 (128)), 34–48. https://doi.org/10.15587/1729-4061.2024.300174

- Kiurchev, S., Kolodiy, O., Burdin, V. (2018). Analysis of pneumoseparators. Proceedings of the Tavria State agrotechnological university, 18 (2), 83–98. Available at: https://oj.tsatu.edu.ua/index.php/pratsi/article/view/60/57

- Aliev, E. B., Yaropud, V. M., Dudin, V. Yr., Pryshliak, V. M., Pryshliak, N. V., Ivlev, V. V. (2018). Research on sunflower seeds separation by airflow. INMATEH Agricultural Engineering, 56 (3), 119–128. Available at: https://inmateh.eu/volumes/pdfs/27.pdf

- Petrachenko, D. О., Dudukova, S. V. (2023). Review of physical-mechanical characteristics of industrial hemp seeds in terms of processing. Scientific Notes of Taurida National V.I. Vernadsky University. Series: Technical Sciences, 34 (73 (3)), 105–109. https://doi.org/10.32782/2663-5941/2023.3.2/18

- Kyurchev, S. V. (2018). Methods of investigation of influence of humidity family of summer on rational speed of air flow in pneumgravitation separator. Machinery & Energetics. Journal of Rural Production Research, 9 (2), 139–141. Available at: https://dglib.nubip.edu.ua/server/api/core/bitstreams/531fdcb7-38cb-43d2-b187-78567a959a40/content

- Aliiev, E., Lupko, C. (2020). Morphological Characteristics and Physical & Mechanical Properties of seeds of small-seeded crops. National Interagency Scientific and Technical Collection of Works. Design, Production and Exploitation of Agricultural Machines, 50, 27–35. https://doi.org/10.32515/2414-3820.2020.50.27-35

- Fadieiev, L. (2021). Pofraktsiynist – oboviazkova skladova pry ochyshchenni zerna ta vyrobnytstvi nasinnia. AgroONE, 70. Available at: https://www.agroone.info/publication/pofrakcijnist-obov-jazkova-skladova-pri-ochishhenni-zerna-ta-virobnictvi-nasinnja/

- Aliiev, E., Chebotarev, V. (2018). Rational precision technological line of separation processes of seed sunflower material. Naukovo-tekhnichnyi biuleten Instytutu oliynykh kultur NAAN, 25, 155–160. Available at: http://aliev.in.ua/doc/stat/2018/stat_21.pdf

- Bredykhin, V. V. (2017). Teoretychni osnovy vibropnevmovidtsentrovoho rozdilennia nasinnievykh materialiv za hustynoiu nasinnia. Kharkiv, 81.

- Tishchenko, L., Kharchenko, S., Kharchenko, F., Bredykhin, V., Tsurkan, O. (2016). Identification of a mixture of grain particle velocity through the holes of the vibrating sieves grain separators. Eastern-European Journal of Enterprise Technologies, 2 (7 (80)), 63–69. https://doi.org/10.15587/1729-4061.2016.65920

- Rezuev, S. B., Bakaev, I. V., Rezuev, V. S. (2011). Separatory dlya zerna. Sovremennoe sostoyanie i tendentsii razvitiya. Hranenie i pererabotka zerna, 9, 36–41.

- Olkhovskyi, V., Dudarev, I. (2021). Separation methods and separators of grain mass. Agricultural Machines, 47, 102–112. https://doi.org/10.36910/acm.vi47.655

- Datsyshyn, O. V., Tkachuk, A. I., Hvozdev O. V. et al. (2008). Tekhnolohichne obladnannia zernopererobnykh ta oliynykh vyrobnytstv. Vinnytsia: Nova Knyha, 488. Available at: http://www.tsatu.edu.ua/ophv/wp-content/uploads/sites/13/О.В.-Дацишин-Технологічне-обладнання-зернопереробних-та-олійних-виробництв.pdf

- Paun, A., Stroescu, Gh., Zaica, Al., Stefan, V., Olan, M., Yasbeck Khozamy, S. (2021). Obtaining “Organic Seeds” of Vegetable and Industrial Plants Using the Aerodynamic Properties of the Seeds. INMATEH Agricultural Engineering, 63 (1), 355–364. https://doi.org/10.35633/inmateh-63-36

- Stroescu, G., Paun, A., Voicea, I., Persu, C., Matache, A., Bunduchi, G. (2020). Influence of moisture content on aerodynamic properties of agricultural products in separation of impurities process. 19th International Scientific Conference Engineering for Rural Development Proceedings. https://doi.org/10.22616/erdev.2020.19.tf315

- Rogovskii, I., Titova, L., Trokhaniak, V., Trokhaniak, O., Stepanenko, S. (2019). Experimental Study in a Pneumatic Microbiocature Separator with Apparatus Camera. Series II - Forestry • Wood Industry • Agricultural Food Engineering, 12 (61 (1)), 117–128. https://doi.org/10.31926/but.fwiafe.2019.12.61.1.10

- Lazykyn, V., Burkov, A., Glushkov, A., Mokiyev, V. (2021). Defining key design parameters for separation chamber of fractioning pneumatic seed separator. 20th International Scientific Conference Engineering for Rural Development Proceedings. https://doi.org/10.22616/erdev.2021.20.tf037

- Choszcz, D. J., Reszczyński, P. S., Kolankowska, E., Konopka, S., Lipiński, A. (2020). The Effect of Selected Factors on Separation Efficiency in a Pneumatic Conical Separator. Sustainability, 12 (7), 3051. https://doi.org/10.3390/su12073051

- Găgeanu, I., Gheorghe, G., Persu, C., Vlăduț, N.-V., Cujbescu, D., Matache, M. G. et al. (2023). Contributions to the Process of Calibrating Corn Seeds Using a Calibrator with Cylindrical Sieves. Applied Sciences, 13 (17), 9927. https://doi.org/10.3390/app13179927

- Bondarenko, L., Halko, S., Matsulevych, O., Tetervak, I., Vershkov, O., Miroshnyk, O. et al. (2022). Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration. Applied Sciences, 13 (1), 21. https://doi.org/10.3390/app13010021

- Golovin, A. Y., Chupin, P. V., Soyunov, A. S., Prokopov, S. P., Abdylmanova, R. H. (2021). Comparative analysis of operation indicators of flat sieve vibrating in horizontal plane. IOP Conference Series: Earth and Environmental Science, 659 (1), 012047. https://doi.org/10.1088/1755-1315/659/1/012047

- Stoica, D., Voicu, G., Popa, L., Constantin, G., Tudor, P. (2020). Assessment indices for the efficiency of the separation process on a sieve with conical separation surface. INMATEH Agricultural Engineering, 60 (1), 193–200. https://doi.org/10.35633/inmateh-60-22

- Special Hull Separator. Available at: https://mehzavod.com.ua/en/catalog/mashina-semenoveechnaya/?sphrase_id=12530

- Khailis, H. A., Konovaliuk, D. M. (1992). Osnovy proektuvannia i doslidzhennia silskohospodarskykh mashyn. Kyiv: NMK VO, 320.

- Oseiko, M. I. (2006). Tekhnolohiya roslynnykh oliy. Kyiv: Varta, 280.

- Montero, L., Ballesteros-Vivas, D., Gonzalez-Barrios, A. F., Sánchez-Camargo, A. del P. (2023). Hemp seeds: Nutritional value, associated bioactivities and the potential food applications in the Colombian context. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.1039180

- Uzunlar, E. A., Kahveci, B. (2021). Nutritional Properties and Health Effects of Hemp Seed. Res & Rev Health Care Open Acc J, 7 (2). Available at: https://lupinepublishers.com/research-and-reviews-journal/pdf/RRHOAJ.MS.ID.000258.pdf

- Saini, P., Panghal, A., Mittal, V., Gupta, R. (2021). Hempseed (Cannabis sativa L.) bulk mass modeling based on engineering properties. Journal of Food Process Engineering, 45 (1). https://doi.org/10.1111/jfpe.13929

- Taheri-Garavand, A., Nassiri, A., Gharibzahedi, S. (2012). Physical and mechanical properties of hemp seed. International Agrophysics, 26 (2), 211–215. https://doi.org/10.2478/v10247-012-0031-9

- Jian, F., Yavari, S., Narendran, R. B., Jayas, D. S. (2018). Physical Properties of Finola® Hemp Seeds: Clean and Containing Dockages. Applied Engineering in Agriculture, 34 (6), 1017–1026. https://doi.org/10.13031/aea.12853

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Viktor Sheichenko, Dmytro Petrachenko, Ivan Rogovskii, Igor Dudnikov, Vitaliy Shevchuk, Denys Sheichenko, Oleksiy Derkach, Ruslan Shatrov

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.