Важливі фактори для структури та механічних властивостей при відновленні компонентів з основного металу термічним розпиленням та зварюванням

DOI:

https://doi.org/10.15587/1729-4061.2024.310239Ключові слова:

чавун, відновлення, термонапилення, зварювання, відстань напилення, мікроструктура, твердістьАнотація

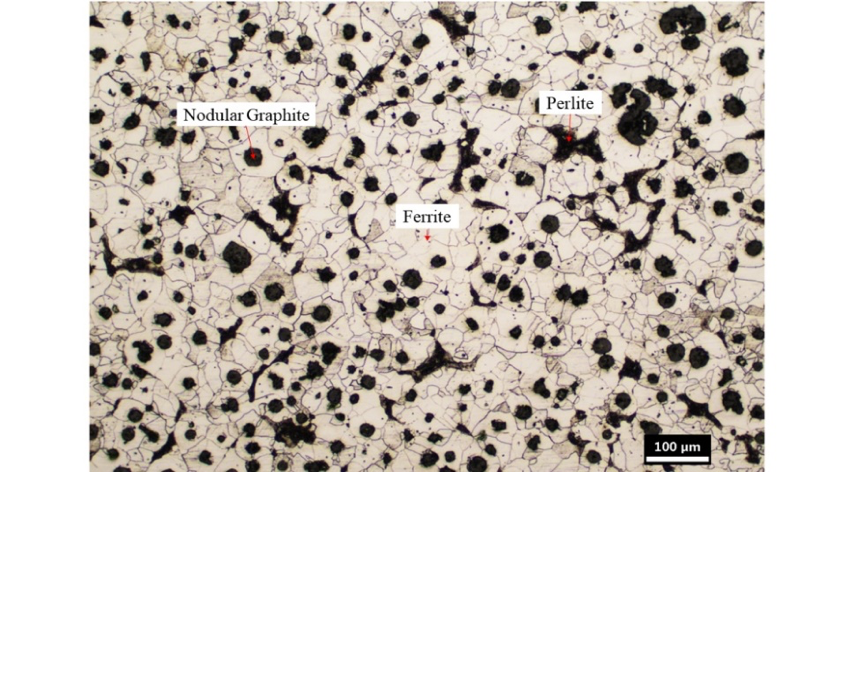

Чавун широко використовується в обробній промисловості завдяки високій міцності і зносостійкості. Однак крихка природа чавуну призводить до частого руйнування тріщин під час формування або використання. Серед методів відновлення, які можна використовувати, – термічне напилення та процес зварювання. Незважаючи на те, що як зварювання, так і термічне розпилення застосовувалися для різних процесів відновлення металу, проте на цю тему знайдено дуже обмежені технічні звіти, а також наукові статті. Таким чином, оптимальні умови відновлення металу обома процесами ще потрібно дослідити. Ці роботи зосереджені на порівнянні термічного напилення та методу зварювання для цілей відновлення чавуну. В експерименті з процесом термічного розпилення акцент було приділено оптимізації відстані розпилення щодо властивостей мікроструктури та твердості. З іншого боку, в експериментальних роботах зі зварювання основна увага приділяється впливу конструкції канавок на мікроструктуру та твердість. Кожна змінна дослідження проводиться для отримання оптимальних результатів відновлення тріщин. Було помічено, що процес термічного розпилення створює меншу площу зони теплового впливу (ЗТВ) порівняно з процесом зварювання, тому має меншу критичну площу. Найвище значення твердості методу термічного розпилення становить 101,33, показане на відстані 30 см. Між тим, найвище значення твердості зони ЗТВ методу зварювання становить 600 HV, показане зразком А. Було встановлено, що з поточних експериментальних робіт процес термічного розпилення дає кращі результати, ніж процес зварювання. Однак значення твердості зразка, отриманого методом зварювання та термічного напилення, залежить від типу використовуваного матеріалу покриття

Посилання

- Reed, G. J. (2014). Understanding cast iron and repairing damaged castings permanently. LOCK-N-STITCH. Available at: https://asremavad.com/wp-content/uploads/2019/03/31-Understanding-cast-iron-and-repairing-damaged-castings-permanently.pdf

- Properties and Selection: Irons, Steels, and High-Performance Alloys (1990). ASM Handbook Committee. https://doi.org/10.31399/asm.hb.v01.9781627081610

- Wube Dametew, A. (2015). Experimental Investigation on Weld Ability of Cast Iron. Science Discovery, 3 (6), 71. https://doi.org/10.11648/j.sd.20150306.15

- Arc Welding of Specific Steels and Cast Irons (2015). KOBELCO. Available at: https://www.kobelco.co.jp/english/welding/events/files/2015_KOBELCO_Specific.pdf

- Askari-Paykani, M., Shayan, M., Shamanian, M. (2014). Weldability of Ferritic Ductile Cast Iron Using Full Factorial Design of Experiment. Journal of Iron and Steel Research International, 21 (2), 252–263. https://doi.org/10.1016/s1006-706x(14)60039-x

- Permana, M. S., Suratman, R. (2012). How to Repair Surface Defect of Gray Cast Iron Components. Proc. XI Annu. Natl. Semin. Mech. Eng. (SNTTM XI) Thermofluid IV Univ. Gadjah Mada. Available at: https://pdfcoffee.com/08-how-to-repair-surface-defect-of-gray-cast-iron-components-pdf-free.html

- Wiryosumarto, H., Okumura, T. (2000). Metal Welding Technology. Jakarta: Pradnya Paramita.

- Butola, R. (2013). Study of Microstructure, Impact Strength on Manual Metal Arc Welding Of Gray Cast Iron Using Enife–Ci Filler Metal. IOSR Journal of Engineering, 3 (7), 37–42. https://doi.org/10.9790/3021-03733742

- Callister, W. D. (1999). Materials Science and Engineering - An Introduction (5th edition). Aircraft Engineering and Aerospace Technology, 71 (6). https://doi.org/10.1108/aeat.1999.12771fae.004

- Gouveia, R., Silva, F., Paiva, O., Andrade, M., Silva, L., Moselli, P., Papis, K. (2017). Study of the Heat-Treatments Effect on High Strength Ductile Cast Iron Welded Joints. Metals, 7 (9), 382. https://doi.org/10.3390/met7090382

- Sonawan, H., Suratman, R. (2006). Introduction to Understanding Metal Welding. Alfabeta. Available at: https://www.scribd.com/document/374354885/Pengantar-Untuk-Memahami-Proses-Pengelasan-Logam

- Maranho, O., Rodrigues, D., Boccalini, M., Sinatora, A. (2008). Influence of parameters of the HVOF thermal spray process on the properties of multicomponent white cast iron coatings. Surface and Coatings Technology, 202 (15), 3494–3500. https://doi.org/10.1016/j.surfcoat.2007.12.026

- Almeida, E. (2000). Surface Treatments and Coatings for Metals. A General Overview. 1. Surface Treatments, Surface Preparation, and the Nature of Coatings. Industrial & Engineering Chemistry Research, 40 (1), 3–14. https://doi.org/10.1021/ie000209l

- Jalali Azizpour, M., Tolouei-Rad, M. (2019). The effect of spraying temperature on the corrosion and wear behavior of HVOF thermal sprayed WC-Co coatings. Ceramics International, 45 (11), 13934–13941. https://doi.org/10.1016/j.ceramint.2019.04.091

- Vardavoulias, M., Economou, S., Papapanos, G. (2023). Industrial Component Restoration Using Thermal Spray Technologies. Surface Modification Technologies XVIII: Proceedings of the Eighteenth International Conference on Surface Modification Technologies Held in Dijon, France November 15-17, 2004: V. 18, 195–200. https://doi.org/10.1201/9781003423874-48

- Sahraoui, T., Guessasma, S., Ali Jeridane, M., Hadji, M. (2010). HVOF sprayed WC–Co coatings: Microstructure, mechanical properties and friction moment prediction. Materials & Design, 31 (3), 1431–1437. https://doi.org/10.1016/j.matdes.2009.08.037

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Raden Dadan Ramdan, Yasya Nur Muhammad, Sihol Christian Lumbantoruan, Irma Pratiwi, Bambang Widyanto, Aditianto Ramelan

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.