Обгрунтування умов надійності виробничого процесу металургійних підприємств через безвідмовне функціонування системи «видобуток сировини – технологічні залізничні маршрути – металургійне виробництво»

DOI:

https://doi.org/10.15587/1729-4061.2024.310679Ключові слова:

страховий запас, відправницький маршрут, дискретно-подієвий принцип, популяція агентів, рівень відмовостійкостіАнотація

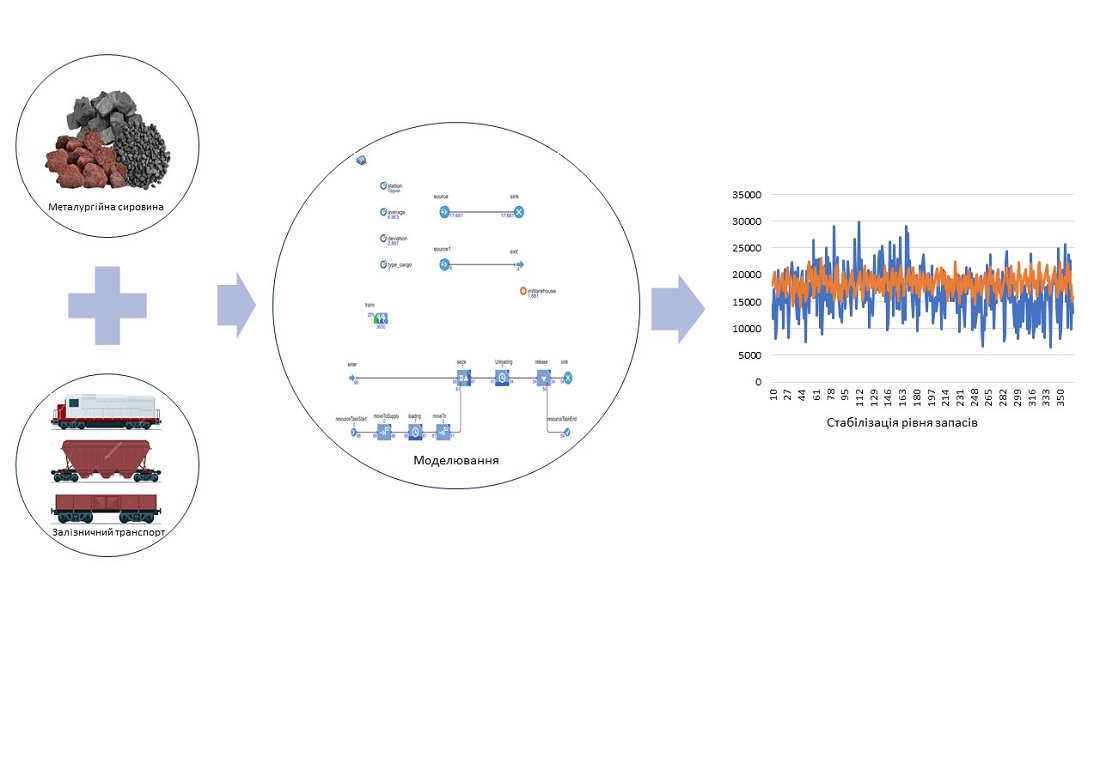

Об’єктом дослідження є процес формування страхових запасів на підприємствах металургійної промисловості. В умовах нерівномірного надходження сировини на металургійні підприємства внаслідок порушення процесу транспортування чи інших причин, виникає необхідність створення страхових запасів з метою забезпечення безперервності виробництва. При цьому необхідно враховувати наявні обмеження, такі як обмежена пропускна спроможність залізничних перегонів та неможливість організації паралельного руху поїздів тощо. Наявність цих обмежень робить неможливим застосування класичних методів вирішення подібних задач, таких як лінійне програмування. Тому для вирішення даної задачі розроблено імітаційну модель на основі дискретно-подієвого принципу у середовищі AnyLogic University Researcher з використанням бібліотек Oracle та компілятора Java SE. За допомогою моделі був формалізований процес обертання відправницьких маршрутів на полігоні залізниці з множиною постачальників та одним вантажоодержувачем. Критерієм оптимізації обрано мінімальні відхилення коливань запасів залізорудного концентрату та коксу. Аналіз результатів моделювання показав, що оптимальний розмір парку залізничних маршрутів на обраному полігоні обертання складає 30 одиниць; при цьому коефіцієнт їх використання складатиме 65%. Також встановлено, що коливання запасів сировини мають «природний характер», що підтверджується нормальним розподілом щільності обсягів запасу. Значення коливань обсягів основної сировини за цих умов складатимуть для залізорудного концентрату ±13115 т/добу, а коксу ±5298 т/добу. Зменшення діапазону коливання обсягів сировини дозволить оптимізувати витрати на створення запасів та впорядкувати транспортну роботу підприємства із забезпечення сировиною

Посилання

- Matsiuk, V. (2017). A study of the technological reliability of railway stations by an example of transit trains processing. Eastern-European Journal of Enterprise Technologies, 1 (3 (85)), 18–24. https://doi.org/10.15587/1729-4061.2017.91074

- Parida, P. (2014). Unlocking Mineral Resource Potential in Southern African Countries: Is Rail Infrastructure up to the Challenge? Transportation Research Procedia, 1 (1), 206–215. https://doi.org/10.1016/j.trpro.2014.07.021

- Vaezi, A., Verma, M. (2017). An analytics approach to dis-aggregate national freight data to estimate hazmat traffic on rail-links and at rail-yards in Canada. Journal of Rail Transport Planning & Management, 7 (4), 291–307. https://doi.org/10.1016/j.jrtpm.2017.12.001

- Grushevska, K., Notteboom, T., Shkliar, A. (2016). Institutional rail reform: The case of Ukrainian Railways. Transport Policy, 46, 7–19. https://doi.org/10.1016/j.tranpol.2015.11.001

- Gupta, D., Dhar, S. (2022). Exploring the freight transportation transitions for mitigation and development pathways of India. Transport Policy, 129, 156–175. https://doi.org/10.1016/j.tranpol.2022.10.013

- Guglielminetti, P., Piccioni, C., Fusco, G., Licciardello, R., Musso, A. (2017). Rail Freight Network in Europe: Opportunities Provided by Re-launching the Single Wagonload System. Transportation Research Procedia, 25, 5185–5204. https://doi.org/10.1016/j.trpro.2018.02.047

- Crozet, Y. (2017). Rail freight development in Europe: how to deal with a doubly-imperfect competition? Transportation Research Procedia, 25, 425–442. https://doi.org/10.1016/j.trpro.2017.05.420

- Bouraima, M. B., Qiu, Y., Yusupov, B., Ndjegwes, C. M. (2020). A study on the development strategy of the railway transportation system in the West African Economic and Monetary Union (WAEMU) based on the SWOT/AHP technique. Scientific African, 8, e00388. https://doi.org/10.1016/j.sciaf.2020.e00388

- Skoczylas, A., Stefaniak, P., Gryncewicz, W., Rot, A. (2023). The Concept of an Intelligent Decision Support System for Ore Transportation in Underground Mine. Procedia Computer Science, 225, 922–931. https://doi.org/10.1016/j.procs.2023.10.079

- Katsman, M. D., Matsiuk, V. I., Myronenko, V. K. (2023). Modeling the reliability of transport under extreme conditions of operation as a queuing system with priorities. Reliability: Theory & Applications, 2 (73), 167–179. https://doi.org/10.24412/1932-2321-2023-273-167-179

- Matsiuk, V., Opalko, V., Savchenko, L., Zagurskiy, O., Matsiuk, N. (2023). Optimisation of transport and technological system parameters of an agricultural enterprise in conditions of partial uncertainty. Naukovij Žurnal «Tehnìka Ta Energetika», 14 (3), 61–71. https://doi.org/10.31548/machinery/3.2023.61

- Anufriyeva, T., Matsiuk, V., Shramenko, N., Ilchenko, N., Pryimuk, O., Lebid, V. (2023). Construction of a simulation model for the transportation of perishable goods along variable routes. Eastern-European Journal of Enterprise Technologies, 2 (4 (122)), 42–51. https://doi.org/10.15587/1729-4061.2023.277948

- Karmanesh, Y., Bagheri, M., Mohammad Hasany, R., Saman Pishvaee, M. (2024). Two-stage stochastic programming approach for fleet sizing and allocating rail wagon under uncertain demand. Computers & Industrial Engineering, 188, 109878. https://doi.org/10.1016/j.cie.2023.109878

- Michal, G., Huynh, N., Shukla, N., Munoz, A., Barthelemy, J. (2017). RailNet: A simulation model for operational planning of rail freight. Transportation Research Procedia, 25, 461–473. https://doi.org/10.1016/j.trpro.2017.05.426

- Prokhorchenko, А., Parkhomenko, L., Kyman, A., Matsiuk, V., Stepanova, J. (2019). Improvement of the technology of accelerated passage of low-capacity car traffic on the basis of scheduling of grouped trains of operational purpose. Procedia Computer Science, 149, 86–94. https://doi.org/10.1016/j.procs.2019.01.111

- Tang, X., Jin, J. G., Shi, X. (2022). Stockyard storage space allocation in large iron ore terminals. Computers & Industrial Engineering, 164, 107911. https://doi.org/10.1016/j.cie.2021.107911

- Song, L., Yu, L., Li, S. (2023). Route optimization of hazardous freight transportation in a rail-truck transportation network considering road traffic restriction. Journal of Cleaner Production, 423, 138640. https://doi.org/10.1016/j.jclepro.2023.138640

- Okorokov, A. (2015). Development of techniques to optimize the technical parameters of transport cargo complexes. Eastern-European Journal of Enterprise Technologies, 2 (3 (74)), 9–14. https://doi.org/10.15587/1729-4061.2015.39792

- Ren, Q., Xu, M. (2024). Injury severity analysis of highway-rail grade crossing crashes in non-divided two-way traffic scenarios: A random parameters logit model. Multimodal Transportation, 3 (1), 100109. https://doi.org/10.1016/j.multra.2023.100109

- Schöbel, A., Aksentijevic, J., Stefan, M., Blieberger, J. (2017). Optimization of rail traffic flow using Kronecker algebra during maintenance on infrastructure. Transportation Research Procedia, 27, 545–552. https://doi.org/10.1016/j.trpro.2017.12.040

- Matsiuk, V., Galan, O., Prokhorchenko, A., Tverdomed, V. (2021). An Agent-Based Simulation for Optimizing the Parameters of a Railway Transport System. Proceedings of the 17th International Conference on ICT in Education, Research and Industrial Applications. Integration, Harmonization and Knowledge Transfer. Volume I: Main Conference. https://ceur-ws.org/Vol-3013/20210121.pdf

- Kozachenko, D., Vernigora, R., Balanov, V., Berezovy, N., Yelnikova, L., Germanyuk, Y. (2016). Evaluation of the Transition to the Organization of Freight Trains Traffic By the Schedule. Transport Problems, 11 (1), 41–48. https://doi.org/10.20858/tp.2016.11.1.4

- Namazov, M., Matsiuk, V., Bulgakova, I., Nikolaienko, I., Vernyhora, R. (2023). Agent-based simulation model of multimodal iron ore concentrate transportation. Naukovij Žurnal «Tehnìka Ta Energetika», 14 (1). https://doi.org/10.31548/machinery/1.2023.46

- Bulakh, M., Okorokov, A., Baranovskyi, D. (2021). Risk System and Railway Safety. IOP Conference Series: Earth and Environmental Science, 666 (4), 042074. https://doi.org/10.1088/1755-1315/666/4/042074

- Panchenko, S., Prokhorchenko, A., Dekarchuk, O., Gurin, D., Mkrtychian, D., Matsiuk, V. (2020). Development of a method for studying the impact of the time reserve value on the reliability of the train schedule based on the epidemiological SIR model. IOP Conference Series: Materials Science and Engineering, 1002 (1), 012016. https://doi.org/10.1088/1757-899x/1002/1/012016

- D’Ariano, A., Meng, L., Centulio, G., Corman, F. (2019). Integrated stochastic optimization approaches for tactical scheduling of trains and railway infrastructure maintenance. Computers & Industrial Engineering, 127, 1315–1335. https://doi.org/10.1016/j.cie.2017.12.010

- Pashchenko, F. F., Kuznetsov, N. A., Ryabykh, N. G., Minashina, I. K., Zakharova, E. M., Tsvetkova, O. A. (2015). Implementation of Train Scheduling System in Rail Transport using Assignment Problem Solution. Procedia Computer Science, 63, 154–158. https://doi.org/10.1016/j.procs.2015.08.326

- Yi, X., Marlière, G., Pellegrini, P., Rodriguez, J., Pesenti, R. (2023). Coordinated train rerouting and rescheduling in large infrastructures. Transportation Research Procedia, 72, 319–326. https://doi.org/10.1016/j.trpro.2023.11.410

- Samà, M., Meloni, C., D’Ariano, A., Corman, F. (2015). A multi-criteria decision support methodology for real-time train scheduling. Journal of Rail Transport Planning & Management, 5 (3), 146–162. https://doi.org/10.1016/j.jrtpm.2015.08.001

- Gupta, P., Bazargan, M., McGrath, R. N. (2003). Simulation model for aircraft line maintenance planning. Annual Reliability and Maintainability Symposium. https://doi.org/10.1109/rams.2003.1182020

- Secchi, D., Grimm, V., Herath, D. B., Homberg, F. (2024). Modeling and theorizing with agent-based sustainable development. Environmental Modelling & Software, 171, 105891. https://doi.org/10.1016/j.envsoft.2023.105891

- Hoffmann, T., Ye, M., Zino, L., Cao, M., Rauws, W., Bolderdijk, J. W. (2024). Overcoming inaction: An agent-based modelling study of social interventions that promote systematic pro-environmental change. Journal of Environmental Psychology, 94, 102221. https://doi.org/10.1016/j.jenvp.2023.102221

- Achter, S., Borit, M., Cottineau, C., Meyer, M., Polhill, J. G., Radchuk, V. (2024). How to conduct more systematic reviews of agent-based models and foster theory development - Taking stock and looking ahead. Environmental Modelling & Software, 173, 105867. https://doi.org/10.1016/j.envsoft.2023.105867

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Oleksandr Zaruba, Andrii Okorokov, Roman Vernyhora, Iryna Zhuravel, Nataliia Barkalova

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.