Виявлення впливу гідротермічного оброблення зерен бобових на накопичення сухих речовин в аквафабі

DOI:

https://doi.org/10.15587/1729-4061.2024.313890Ключові слова:

зерна бобових, сухі речовини, гідромеханічне оброблення, гідротермічне оброблення, аквафаба, кінетика вологовмістуАнотація

Бобові – доступне джерело рослинного білку, клітковини, вітамінів, завдяки високій поживній та біологічній цінності широко використовуються в харчуванні різних категорій споживачів. Основні методи оброблення бобових включають гідромеханічне та гідротермічне оброблення, яке спрямоване на досягнення кулінарної готовності відварних бобових. Дослідження параметрів зазначеного технологічного процесу на накопичення сухих речовин в аквафабі дозволить впливати на склад та властивості цієї рідини, що надасть можливості для її використання в харчовій промисловості.

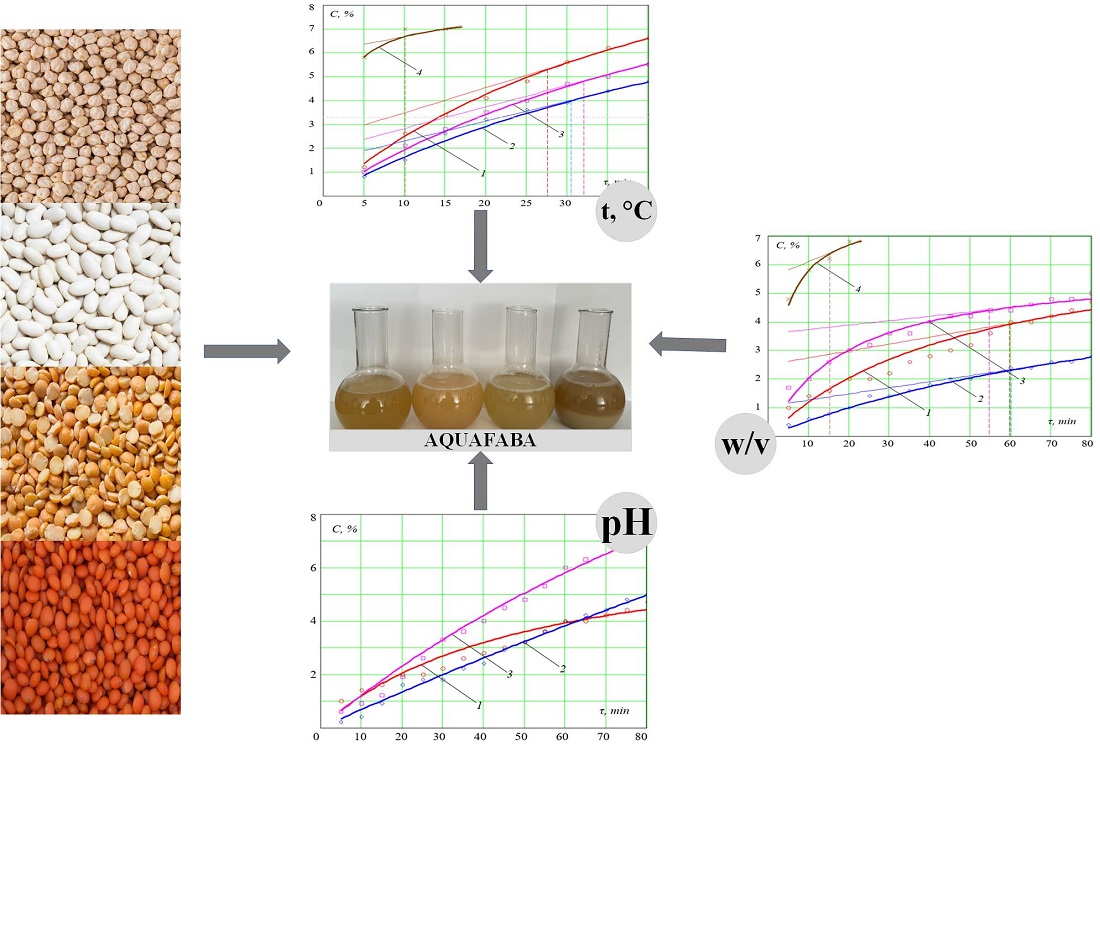

Експериментально досліджено вплив гідротермічного оброблення зерен бобових на накопичення сухих речовин в аквафабі, кінетику вологовмісту різних видів зерен бобових, що дозволило визначити раціональні параметри гідромеханічного та гідротермічного оброблення нуту, квасолі, гороху, сочевиці з одержанням відварених зерен бобових та аквафаби.

Визначено, що при гідромеханічному обробленні інтенсивне поглинання вологи відбувається за перші години та сягає до 80 % від початкової маси, після чого інтенсивність водопоглинання дещо знижується. Встановлено раціональні технологічні параметри гідротермічного оброблення зерен бобових двома способами – основним (варіння за температури 99±1 °С) та під тиском (варіння у скороварці за температури 120±1 °С) у взаємозв’язку «досягнення готовності бобових – вміст сухих речовин в аквафабі». Використання вищеозначених способів гідротермічного оброблення зерен бобових дозволяє отримати вміст сухих речовин в аквафабі в діапазоні 2.8–4.8 % для варіння основним способом та 3.9–7.0 % за умов варіння під тиском. Для розуміння зазначених процесів щодо впливу гідротермічного оброблення зерен бобових на накопичення сухих речовин використано модель Пелега.

Отримані експериментальні дані можуть бути використані для обґрунтування параметрів технологічного процесу виробництва харчової продукції на основі бобових

Посилання

- Dehtiar, V. V., Radchenko, A. E., Grynchenko, N. H., Grinchenko, O. O., (2023). Technological and economic aspects of using legumes in food technology: a mini-review. Journal of Chemistry and Technologies, 31 (4), 896–906. https://doi.org/10.15421/jchemtech.v31i4.287753

- Huang, S., Liu, Y., Zhang, W., Dale, K. J., Liu, S., Zhu, J., Serventi, L. (2017). Composition of legume soaking water and emulsifying properties in gluten-free bread. Food Science and Technology International, 24 (3), 232–241. https://doi.org/10.1177/1082013217744903

- Nergiz, C., Gökgöz, E. (2007). Effects of traditional cooking methods on some antinutrients and in vitro protein digestibility of dry bean varieties (Phaseolus vulgaris L.) grown in Turkey. International Journal of Food Science & Technology, 42 (7), 868–873. https://doi.org/10.1111/j.1365-2621.2006.01297.x

- Carvalho, L. M., Corrêa, M. M., Pereira, E. J., Nutti, M. R., Carvalho, J. L. V., Ribeiro, E. M., Freitas, S. C. (2012). Iron and zinc retention in common beans (Phaseolus vulgarisL.) after home cooking. Food & Nutrition Research, 56 (1), 15618. https://doi.org/10.3402/fnr.v56i0.15618

- Munthali, J., Nkhata, S. G., Masamba, K., Mguntha, T., Fungo, R., Chirwa, R. (2022). Soaking beans for 12 h reduces split percent and cooking time regardless of type of water used for cooking. Heliyon, 8 (9), e10561. https://doi.org/10.1016/j.heliyon.2022.e10561

- Martínez-Pineda, M., Yagüe-Ruiz, C., Caverni-Muñoz, A., Vercet-Tormo, A. (2019). Cooking Legumes: A Way for Their Inclusion in the Renal Patient Diet. Journal of Renal Nutrition, 29 (2), 118–125. https://doi.org/10.1053/j.jrn.2018.08.001

- Schoeninger, V., Coelho, S. R. M., Christ, D., Sampaio, S. C. (2014). Processing parameter optimization for obtaining dry beans with reduced cooking time. LWT - Food Science and Technology, 56 (1), 49–57. https://doi.org/10.1016/j.lwt.2013.11.007

- Liu, Y., Ragaee, S., Marcone, M. F., Abdel-Aal, E.-S. M. (2020). Composition of Phenolic Acids and Antioxidant Properties of Selected Pulses Cooked with Different Heating Conditions. Foods, 9 (7), 908. https://doi.org/10.3390/foods9070908

- Ávila, B. P., Santos dos Santos, M., Nicoletti, A. M., Alves, G. D., Elias, M. C., Monks, J., Gularte, M. A. (2015). Impact of Different Salts in Soaking Water on the Cooking Time, Texture and Physical Parameters of Cowpeas. Plant Foods for Human Nutrition, 70 (4), 463–469. https://doi.org/10.1007/s11130-015-0504-7

- Fabbri, A. D. T., Crosby, G. A. (2016). A review of the impact of preparation and cooking on the nutritional quality of vegetables and legumes. International Journal of Gastronomy and Food Science, 3, 2–11. https://doi.org/10.1016/j.ijgfs.2015.11.001

- Grossi Bovi Karatay, G., Rebellato, A. P., Joy Steel, C., Dupas Hubinger, M. (2022). Chickpea Aquafaba-Based Emulsions as a Fat Replacer in Pound Cake: Impact on Cake Properties and Sensory Analysis. Foods, 11 (16), 2484. https://doi.org/10.3390/foods11162484

- Fuentes Choya, P., Combarros-Fuertes, P., Abarquero Camino, D., Renes Bañuelos, E., Prieto Gutiérrez, B., Tornadijo Rodríguez, M. E., Fresno Baro, J. M. (2023). Study of the Technological Properties of Pedrosillano Chickpea Aquafaba and Its Application in the Production of Egg-Free Baked Meringues. Foods, 12 (4), 902. https://doi.org/10.3390/foods12040902

- Alsalman, F. B., Tulbek, M., Nickerson, M., Ramaswamy, H. S. (2020). Evaluation and optimization of functional and antinutritional properties of aquafaba. Legume Science, 2 (2). https://doi.org/10.1002/leg3.30

- Nguyen, T. M. N., Ngọc, N. P., Quoc, L. P. T., Tran, G. B. (2021). Application of Chickpeas Aquafaba with Pre-treatment as Egg Replacer in Cake Production. Chemical Engineering Transactions, 89, 7–12. https://doi.org/10.3303/CET2189002

- Domingues Landert, M., Xavier Zaminelli, C., Dário Capitani, C. (2021). Aquafaba obtained from chickpea cooking: chemical characterization, standardization of use and viability in a recipe. Demetra: Food, Nutrition & Health / Alimentação, Nutrição & Saúde, 16 (1).

- Srungarapu, R., Mohammad, L. A., Mahendrakar, M. D., Chand, U., Jagarlamudi Venkata, R., Kondamudi, K. P. et al. (2022). Genetic variation for grain protein, Fe and Zn content traits in chickpea reference set. Journal of Food Composition and Analysis, 114, 104774. https://doi.org/10.1016/j.jfca.2022.104774

- Technical, A. (2009). Method for Determining Water Hydration Capacity and Percentage of Unhydrated Seeds of Pulses. AACC International Approved Methods. https://doi.org/10.1094/aaccintmethod-56-35.01

- Technical, A. (2009). Moisture--Air-Oven Methods. AACC International Approved Methods. https://doi.org/10.1094/aaccintmethod-44-15.02

- Pogozhikh, M., Pak, A., Chekanov, M., Ishtvan, E., Pavliuk, I. (2014). Researches of system water of food raw materials by thermodynamic and molecular-kinetic methods. Eastern-European Journal of Enterprise Technologies, 5 (11 (71)), 42–46. https://doi.org/10.15587/1729-4061.2014.27790

- Peleg, M. (1988). An Empirical Model for the Description of Moisture Sorption Curves. Journal of Food Science, 53 (4), 1216–1217. https://doi.org/10.1111/j.1365-2621.1988.tb13565.x

- Shafaei, S. M., Masoumi, A. A., Roshan, H. (2016). Analysis of water absorption of bean and chickpea during soaking using Peleg model. Journal of the Saudi Society of Agricultural Sciences, 15 (2), 135–144. https://doi.org/10.1016/j.jssas.2014.08.003

- Li, P., Li, Y., Wang, L., Zhang, H., Qi, X., Qian, H. (2020). Study on water absorption kinetics of black beans during soaking. Journal of Food Engineering, 283, 110030. https://doi.org/10.1016/j.jfoodeng.2020.110030

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Olha Hrynchenko, Valentyna Dehtiar, Anna Radchenko, Andrey Pak, Iryna Smetanska, Fedor Percevoy

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.