Визначення оптимальної температури окислення неізотермічних впорскувань рідких палив з використанням моделювання на основі статистичного розподілу крапель за розмірами

DOI:

https://doi.org/10.15587/1729-4061.2024.316100Ключові слова:

рідке паливо, розпилення, згоряння, викиди, одноструменеве впорскування, теплові двигуниАнотація

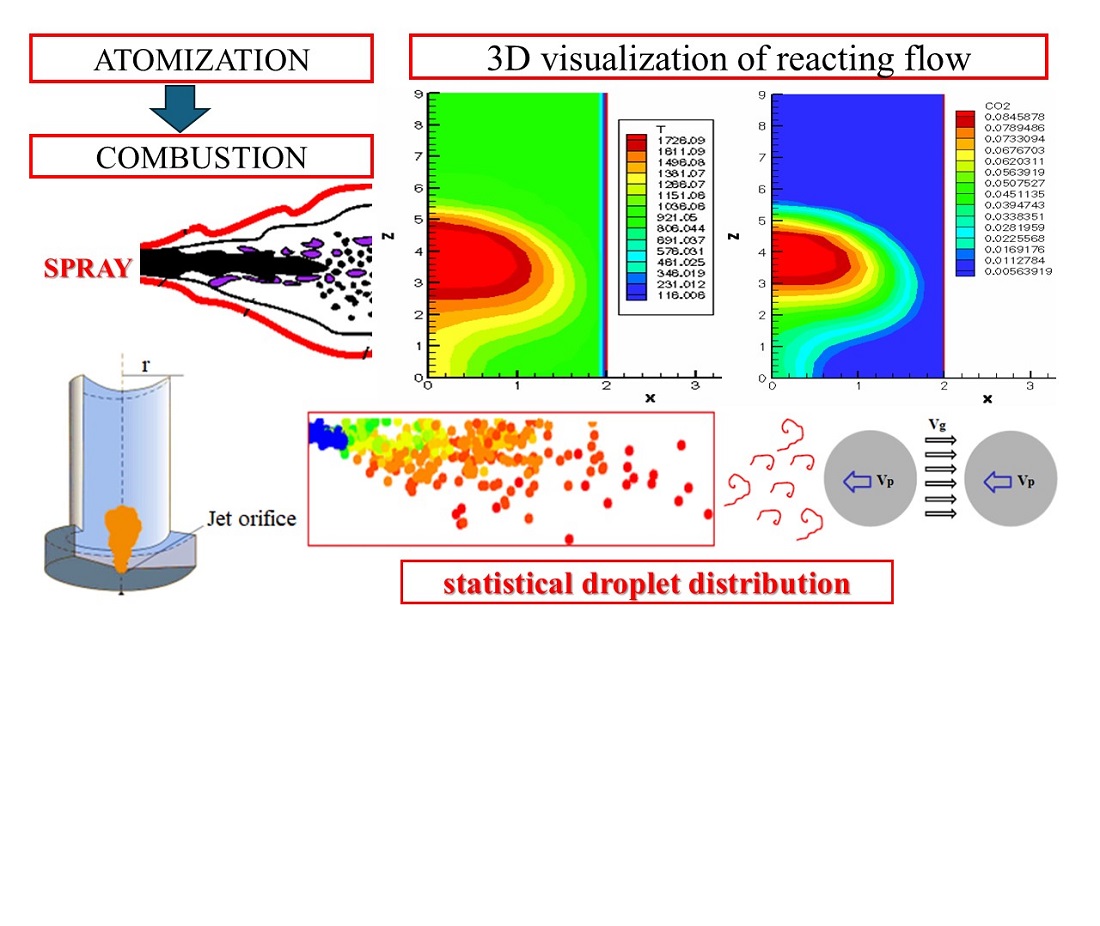

За допомогою прямого чисельного моделювання на основі статистичної моделі, що враховує процеси розпилення, розподілу та згоряння крапель, були досліджені одноструменеві впорскування рідких вуглеводневих палив (ізооктану і додекану) в умовах високої турбулентності. Об’єктами дослідження є процеси тепломасообміну при розпиленні та згорянні впорскувань рідких палив у камерах згоряння теплових двигунів. Отримано дані про розподіл температури та концентрації вуглекислого газу в паливоповітряній суміші, розподіл крапель, їх швидкості та середній радіус Заутера в межах окислення ізооктану і додекану в камері згоряння двигуна. Дослідження впливу початкової температури окислювача на процеси розпилення та згоряння крапель показало, що оптимальна температура для обох видів палива становить 900 К. Підтверджено гарну відповідність отриманих результатів моделювання теоретичним та експериментальним даним.

Завдяки комплексному використанню підходів статистичної теорії, чисельних алгоритмів і методів комп’ютерного 3D-моделювання, отримані результати відрізняються високою точністю, ефективністю скорочення обчислювальних ресурсів, науковою новизною в типі розпилення крапель та практичною застосовністю в технологічних рішеннях не тільки для одноструменевих, але й багатоструменевих впорскувань рідких палив та вивчення явищ взаємодії струменів.

Отримані результати досліджень можуть бути використані при розробці різних двигунів внутрішнього згоряння з різними типами розпилення, що дозволить одночасно вирішувати завдання оптимізації процесу згоряння, підвищення повноти згоряння палива і зниження викидів шкідливих речовин

Посилання

- Messerle, V. E., Askarova, A. S., Bolegenova, S. A., Yu Maximov, V., Nugymanova, A. O. (2019). 3D-modelling of Kazakhstan low-grade coal burning in power boilers of thermal power plant with application of plasma gasification and stabilization technologies. Journal of Physics: Conference Series, 1261 (1), 012022. https://doi.org/10.1088/1742-6596/1261/1/012022

- Mislyuk, O., Khomenko, E., Yehorova, O., Zhytska, L. (2023). Assessing risk caused by atmospheric air pollution from motor vehicles to the health of population in urbanized areas. Eastern-European Journal of Enterprise Technologies, 1 (10 (121)), 19–26. https://doi.org/10.15587/1729-4061.2023.274174

- Zaporozhets, O., Synylo, K., Karpenko, S., Krupko, A. (2021). Improvementof the computer model of air pollution estimation due to emissions of stationary sources of airports and compressor stations. Eastern-European Journal of Enterprise Technologies, 3 (10 (111)), 54–64. https://doi.org/10.15587/1729-4061.2021.236125

- Bolegenova, S. A. (2024). Simulation of liquid fuel spray formation and distribution in a reacting turbulent flow. Eurasian Physical Technical Journal, 21 (2 (48)), 22–30. https://doi.org/10.31489/2024no2/22-30

- Ritchie, H., Roser, M. (2022). Our World in Data. Kazakhstan: CO2 Country Profile. Available at: https://ourworldindata.org/co2/country/kazakhstan

- Kazakhstan Greenhouse Gas (GHG) Emissions 1990-2024. Available at: https://www.macrotrends.net/global-metrics/countries/KAZ/kazakhstan/ghg-greenhouse-gas-emissions

- Ecological indicators of environmental monitoring and assessment. Bureau of National Statistics of the Agency for Strategic planning and reforms of the Republic of Kazakhstan. Available at: https://stat.gov.kz/en/ecologic-indicators/28463/greenhouse_gas_emissions/

- Statistics of environment. Key indicators. Bureau of National Statistics of the Agency for Strategic planning and reforms of the Republic of Kazakhstan. Available at: https://stat.gov.kz/en/industries/environment/stat-eco/

- Аskarova, А., Bolegenova, S., Маximov, V., Bekmukhamet, A., Gabitova, Z., Beketayeva, М. (2014). Control of Harmful Emissions Concentration into the Atmosphere of Megacities of Kazakhstan Republic. IERI Procedia, 10, 252–258. https://doi.org/10.1016/j.ieri.2014.09.085

- Bolegenova, S., Askarova, A., Ospanova, S., Zhumagaliyeva, S., Makanova, A., Aldiyarova, A. et al. (2024). Technology of reducing greenhouse gas emissions for decarbonization and decreasing anthropogenic pressure on the environment. Physical Sciences and Technology, 11 (1-2), 64–75. https://doi.org/10.26577/phst2024v11i1a8

- Reitz, R. D. (1987). Modeling atomization processes in high-pressure vaporizing sprays. Atomization and Spray Technology, 3, 309–337. Available at: https://uwmadison.app.box.com/v/AandS

- Villermaux, E. (2007). Fragmentation. Annual Review of Fluid Mechanics, 39 (1), 419–446. https://doi.org/10.1146/annurev.fluid.39.050905.110214

- Yi, Y., Reitz, R. D. (2004). Modeling the primary breakup of high-speed jets. Atomization and Sprays, 14 (1), 53–80. https://doi.org/10.1615/atomizspr.v14.i1.40

- Tanner, F. X. (2004). Development and validation of a cascade atomization and drop breakup model for high-velocity dense sprays. Atomization and Sprays, 14 (3), 211–242. https://doi.org/10.1615/atomizspr.v14.i3.20

- Anez, J., Ahmed, A., Hecht, N., Duret, B., Reveillon, J., Demoulin, F. X. (2019). Eulerian-Lagrangian spray atomization model coupled with interface capturing method for diesel injectors. International Journal of Multiphase Flow, 113, 325–342. https://doi.org/10.1016/j.ijmultiphaseflow.2018.10.009

- Arcoumanis, C., Gavaises, M. (1998). Linking nozzle flow with spray characteristics in a diesel fuel injection system. Atomization and Sprays, 8 (3), 307–347. https://doi.org/10.1615/atomizspr.v8.i3.50

- Andriotis, A., Gavaises, M., Arcoumanis, C. (2008). Vortex flow and cavitation in diesel injector nozzles. Journal of Fluid Mechanics, 610, 195–215. https://doi.org/10.1017/s0022112008002668

- Andriotis, A., Gavaises, M. (2009). Influence of vortex flow and cavitation on near-nozzle diesel spray dispersion angle. Atomization and Sprays, 19 (3), 247–261. https://doi.org/10.1615/atomizspr.v19.i3.30

- Berezovskaya, I. E. (2023). Investigation of the influence of liquid fuel injection rate on the combustion process using KIVA-II software. Eurasian Physical Technical Journal, 20(3(45)), 43–51. https://doi.org/10.31489/2023no3/43-51

- Gorokhovski, M. A., Oruganti, S. K. (2021). Stochastic models for the droplet motion and evaporation in under-resolved turbulent flows at a large Reynolds number. Journal of Fluid Mechanics, 932. https://doi.org/10.1017/jfm.2021.916

- Han, Z., Fan, L., Reitz, R. D. (1997). Multidimensional Modeling of Spray Atomization and Air-Fuel Mixing in a Direct-Injection Spark-Ignition Engine. SAE Technical Paper Series. https://doi.org/10.4271/970884

- Khan, M. M., Hélie, J., Gorokhovski, M. (2018). Computational methodology for non-evaporating spray in quiescent chamber using Large Eddy Simulation. International Journal of Multiphase Flow, 102, 102–118. https://doi.org/10.1016/j.ijmultiphaseflow.2018.01.025

- Dhande, D. Y., Sinaga, N., Dahe, K. B. (2021). Study on combustion, performance and exhaust emissions of bioethanol-gasoline blended spark ignition engine. Heliyon, 7 (3), e06380. https://doi.org/10.1016/j.heliyon.2021.e06380

- Sahoo, S., Srivastava, D. K. (2023). Numerical analysis of performance, combustion, and emission characteristics of PFI gasoline, PFI CNG, and DI CNG engine. Energy, 278, 127749. https://doi.org/10.1016/j.energy.2023.127749

- Askarova, A., Bolegenova, S., Ospanova, Sh., Slavinskaya, N., Aldiyarova, A., Ungarova, N. (2021). Simulation of non-isothermal liquid sprays under large-scale turbulence. Physical Sciences and Technology, 8 (2). https://doi.org/10.26577/phst.2021.v8.i2.04

- Chang, M., Kim, H., Zhou, B., Park, S. (2023). Spray collapse resistance of GDI injectors with different hole structures under flash boiling conditions. Energy, 268, 126689. https://doi.org/10.1016/j.energy.2023.126689

- Oruganti, S. K., Gorokhovski, M. A. (2024). Stochastic models in the under-resolved simulations of spray formation during high-speed liquid injection. Physics of Fluids, 36 (5). https://doi.org/10.1063/5.0206826

- Askarova, A., Bekmukhamet, A., Bolegenova, S., Ospanova, S., Symbat, B., Maximov, V. et al. (2016). 3-D Modeling of Heat and Mass Transfer during Combustion of Solid Fuel in Bkz-420-140-7C Combustion Chamber of Kazkhstan. Journal of Applied Fluid Mechanics, 9 (2), 699–709. https://doi.org/10.18869/acadpub.jafm.68.225.22881

- Leithner, R., Askarova, A., Bolegenova, S., Bolegenova, S., Maximov, V., Ospanova, S. et al. (2016). Computational modeling of heat and mass transfer processes in combustion chamber at power plant of Kazakhstan. MATEC Web of Conferences, 76, 06001. https://doi.org/10.1051/matecconf/20167606001

- Bolegenova, S., Askarova, A., Slavinskaya, N., Ospanova, Sh., Maxutkhanova, A., Aldiyarova, A., Yerbosynov, D. (2022). Statistical modeling of spray formation, combustion, and evaporation of liquid fuel droplets. Physical Sciences and Technology, 9 (2). https://doi.org/10.26577/phst.2022.v9.i2.09

- Khan, M. M., Hélie, J., Gorokhovski, M., Sheikh, N. A. (2017). Experimental and numerical study of flash boiling in gasoline direct injection sprays. Applied Thermal Engineering, 123, 377–389. https://doi.org/10.1016/j.applthermaleng.2017.05.102

- Gorokhovski, M., Jouanguy, J., Chtab-Desportes, A. (2009). Stochastic model of the near-to-injector spray formation assisted by a high-speed coaxial gas jet. Fluid Dynamics Research, 41 (3), 035509. https://doi.org/10.1088/0169-5983/41/3/035509

- Arcoumanis, C., Cutter, P., Whitelaw, D. S. (1998). Heat Transfer Processes in Diesel Engines. Chemical Engineering Research and Design, 76 (2), 124–132. https://doi.org/10.1205/026387698524695

- Huang, J., Zhao, X. (2019). Numerical simulations of atomization and evaporation in liquid jet flows. International Journal of Multiphase Flow, 119, 180–193. https://doi.org/10.1016/j.ijmultiphaseflow.2019.07.018

- García-Contreras, R., Armas, O., Mata, C., Villanueva, O. (2017). Impact of Gas To Liquid and diesel fuels on the engine cold start. Fuel, 203, 298–307. https://doi.org/10.1016/j.fuel.2017.04.116

- Dhar, A., Tauzia, X., Maiboom, A. (2016). Phenomenological models for prediction of spray penetration and mixture properties for different injection profiles. Fuel, 171, 136–142. https://doi.org/10.1016/j.fuel.2015.12.022

- Zhu, L., Wu, K., Zhang, E., She, Y., Zhan, W., Liu, Q. (2015). A modified model for calculating Theoretical Flame Temperature in blast furnace and its application. Journal of Iron and Steel Research International, 22 (1), 9–14. https://doi.org/10.1016/s1006-706x(15)60002-4

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Aliya Askarova, Saltanat Bolegenova, Shynar Ospanova, Symbat Bolegenova, Gulzhakhan Baidullayeva, Kazyret Berdikhan, Akbota Nussipzhan

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.