Structural improvement of a mobile device for pre-heated treatment of vegetable raw materials

DOI:

https://doi.org/10.15587/1729-4061.2024.318559Keywords:

functional apparatus, plant raw materials, polycomponent semi-finished products, preliminary heat treatmentAbstract

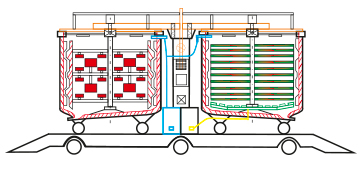

The object of this study is the heat treatment of multicomponent masses, for example, Jerusalem artichoke, pumpkin, and black chokeberry, during thickening and drying in an improved mobile functional apparatus for preliminary heat operations. The engineering solution is aimed at the implementation of resource-saving preliminary thermal operations of plant raw materials on mobile functional equipment. The structural difference of the device for the preliminary heat treatment of plant raw materials is the presence of a mobile platform with a carousel arrangement of rolling containers with changeable working elements. The device provides simultaneous implementation of thermal operations in three functional containers. The vacuum compartment and the steam generator with flexible technical lines are connected to functional tanks equipped with bubbler disks to improve heat transfer. The central platform has a microprocessor-based automatic control unit and a spring mechanism for lifting the cover equipped with Peltier elements for secondary heat conversion. The tanks are heated by a film resistive electric heater. Peltier elements are mounted on the inner surface of the cover to convert secondary heat for autonomous operation of the fan. For preliminary heat treatment of liquid media, the functional container is additionally equipped with a stirrer with a heated surface (the usable area of the thermal surface is 0.28 m2).

The duration of reaching a stationary temperature regime (50 °С) of the multicomponent mass (Jerusalem artichoke – 50 %, pumpkin – 40 %, and chokeberry – 10 %) in a mobile device is 31.4 % less than in a classic design. The duration of the drying process in the functional device is 40 minutes, and in the conventional KVM-150 device – 60 minutes. A 1.8-fold decrease in the specific metal capacity was established. Total heat losses are reduced by 1.24 times, and the usable heating surface is increased by 1.3 times

References

- Zdravkovic, M., Snoeck, E. R., Zicari, A., Vranken, L., Heinz, V., Smetana, S., Aganovic, K. (2021). Sustainability assessment of mobile juice processing unit: Farmers perspective. Future Foods, 4, 100064. https://doi.org/10.1016/j.fufo.2021.100064

- Nazarova, L. V. (2014). Stan kharchovoi promyslovosti Ukrainy ta perspektyvy pidpryiemstv haluzi na zovnishnikh rynkakh. Available at: http://globalnational.in.ua

- Pathmanaban, P., Gnanavel, B. K., Anandan, S. S., Sathiyamurthy, S. (2023). Advancing post-harvest fruit handling through AI-based thermal imaging: applications, challenges, and future trends. Discover Food, 3(1). https://doi.org/10.1007/s44187-023-00068-2

- Sashnova, M., Zahorulko, A., Savchenko, T., Gakhovich, S., Parkhomenko, I., Pankov, D. (2020). Improving the quality of the technological process of packaging shape formation based on the information structure of an automated system. Eastern-European Journal of Enterprise Technologies, 3 (2 (105)), 28–36. https://doi.org/10.15587/1729-4061.2020.205226

- Salifou, A., Konfo, C., Bokossa, A., Nicodème, C., Tchobo, F. P., Soumanou, M. (2023). Innovative approaches in food processing: enhancing quality, preservation, and safety through advanced technologies: A review. World Journal of Advanced Research and Reviews, 20 (2), 637–648. https://doi.org/10.30574/wjarr.2023.20.2.2297

- Hubbermann, E. M.; Carle, R., Schweiggert, R. M. (Eds). (2016). Coloring of Low-Moisture and Gelatinized Food Products. Handbook on Natural Pigments in Food and Beverages. Woodhead Publishing, 179–196. https://doi.org/10.1016/b978-0-08-100371-8.00008-7

- Zahorulko, A., Zagorulko, A., Chuiko, L., Solomon, A., Sushko, L., Tesliuk, Y. et al. (2023). Improving the reactor for thickening organic plant-based polycomponent semi-finished products with high degree of readiness. Eastern-European Journal of Enterprise Technologies, 6 (11 (126)), 103–111. https://doi.org/10.15587/1729-4061.2023.294119

- König, L. M., Renner, B. (2019). Boosting healthy food choices by meal colour variety: results from two experiments and a just-in-time Ecological Momentary Intervention. BMC Public Health, 19 (1). https://doi.org/10.1186/s12889-019-7306-z

- Habanova, M., Saraiva, J. A., Holovicova, M., Moreira, S. A., Fidalgo, L. G., Haban, M. et al. (2019). Effect of berries/apple mixed juice consumption on the positive modulation of human lipid profile. Journal of Functional Foods, 60, 103417. https://doi.org/10.1016/j.jff.2019.103417

- Pylypenko, O. Ye. (2017). Development of Ukrainian Food Industry. Naukovi pratsi NUKhT, 23 (3), 15–25. Available at: http://www.irbis-nbuv.gov.ua/cgi-bin/irbis_nbuv/cgiirbis_64.exe?I21DBN=LINK&P21DBN=UJRN&Z21ID=&S21REF=10&S21CNR=20&S21STN=1&S21FMT=ASP_meta&C21COM=S&2_S21P03=FILA=&2_S21STR=Npnukht_2017_23_3_4

- Ruiz Rodríguez, L. G., Zamora Gasga, V. M., Pescuma, M., Van Nieuwenhove, C., Mozzi, F., Sánchez Burgos, J. A. (2021). Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Research International, 140, 109854. https://doi.org/10.1016/j.foodres.2020.109854

- Minenko, S., Cherevko, O., Skrynnik, V., Tesliuk, H., Bondar, M., Skoromna, O. et al. (2023). Improvement of the vacuum evaporator for the production of paste-like semi-finished products with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 5 (11 (125)), 76–83. https://doi.org/10.15587/1729-4061.2023.288896

- Marković, M. S., Radosavljević, D. B., Pavićević, V. P., Ristić, M. S., Milojević, S. Ž., Bošković-Vragolović, N. M., Veljković, V. B. (2018). Influence of common juniper berries pretreatment on the essential oil yield, chemical composition and extraction kinetics of classical and microwave-assisted hydrodistillation. Industrial Crops and Products, 122, 402–413. https://doi.org/10.1016/j.indcrop.2018.06.018

- Telezhenko, L. N., Bezusov, A. T. (2004). Biologicheski aktivnye veshchestva fruktov i ovoshchei: sokhranenie pri pererabotke. Odessa: Optimum, 268.

- Fellows, P. J.; Fellows, P. J. (Ed.) (2022). Properties of foods and principles of processing. Food Processing Technology. Woodhead Publishing, 3–95. https://doi.org/10.1016/b978-0-323-85737-6.00007-8

- Sruthy, G. N., Sandhya, K. R., Kumkum, C. R., Mythri, R., Sharma, M.; Tarafdar, A., Pandey, A., Sirohi, R., Soccol, C., Dussap, C.-G. (Eds). (2022). Thermal processing technologies for food. Current Developments in Biotechnology and Bioengineering. Elsevier, 263–300. https://doi.org/10.1016/b978-0-323-91158-0.00014-4

- Zahorulko, A., Zagorulko, A., Cherevko, O., Dromenko, O., Solomon, A., Yakobchuk, R., Bondarenko, O., Nozdrina, N. (2021). Determination of the heat transfer coefficient of a rotary film evaporator with a heating film-forming element. Eastern-European Journal of Enterprise Technologies, 6 (8 (114)), 41–47. https://doi.org/10.15587/1729-4061.2021.247283

- Dolores Alvarez, M., Canet, W. (2013). Time-independent and time-dependent rheological characterization of vegetable-based infant purees. Journal of Food Engineering, 114 (4), 449–464. https://doi.org/10.1016/j.jfoodeng.2012.08.034

- Adalja, A., Lichtenberg, E. (2018). Implementation challenges of the food safety modernization act: Evidence from a national survey of produce growers. Food Control, 89, 62–71. https://doi.org/10.1016/j.foodcont.2018.01.024

- Zahorulko, A., Zagorulko, A., Cherevko, O., Dromenko, O., Solomon, A., Yakobchuk, R. (2021). Determination of the heat transfer coefficient of a rotary film evaporator with a heating film-forming element. Eastern-European Journal of Enterprise Technologies, 6 (8 (114)), 41–47. https://doi.org/10.15587/1729-4061.2021.247283

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Zahorulko, A. M., Zahorulko, O. Ye. (2021). Pat. No. 149981 UA. Plivkopodibnyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. MPK H05B 3/36, B01D 1/22, G05D 23/19. No. u202102839; declareted: 28.05.2021; published: 23.12.2021, Bul. No. 51, 4. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=279802

- MZ-2S-316 – Reaktor vakuum vyparnyi. Available at: https://www.oborud.info/product/jump.php?6109&c=619

- Cherevko, O. I., Maiak, O. A., Kostenko, S. M., Sardarov, A. M. (2019). Experimental and simulation modeling of the heat exchanche process while boiling vegetable juice. Prohresyvni tekhnika ta tekhnolohii kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 1 (29), 75–85. Available at: http://nbuv.gov.ua/UJRN/Pt_2019_1_9

- Zahorulko, A., Zagorulko, A., Fedak, N., Sabadash, S., Kazakov, D., Kolodnenko, V. (2019). Improving a vacuum-evaporator with enlarged heat exchange surface for making fruit and vegetable semi-finished products. Eastern-European Journal of Enterprise Technologies, 6 (11 (102)), 6–13. https://doi.org/10.15587/1729-4061.2019.178764

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Zahorulko, Iryna Voronenko, Lyudmila Chuiko, Nataliia Tytarenko, Eldar Ibaiev, Alla Solomon, Oksana Skoromna, Maksym Prykhodko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.