Determining the effect of triangular interwindow openings in a bus body on its structure, strength, and passive safety

DOI:

https://doi.org/10.15587/1729-4061.2025.321663Keywords:

interwindow openings, bus body, structural optimization, von Mises stress, passive safetyAbstract

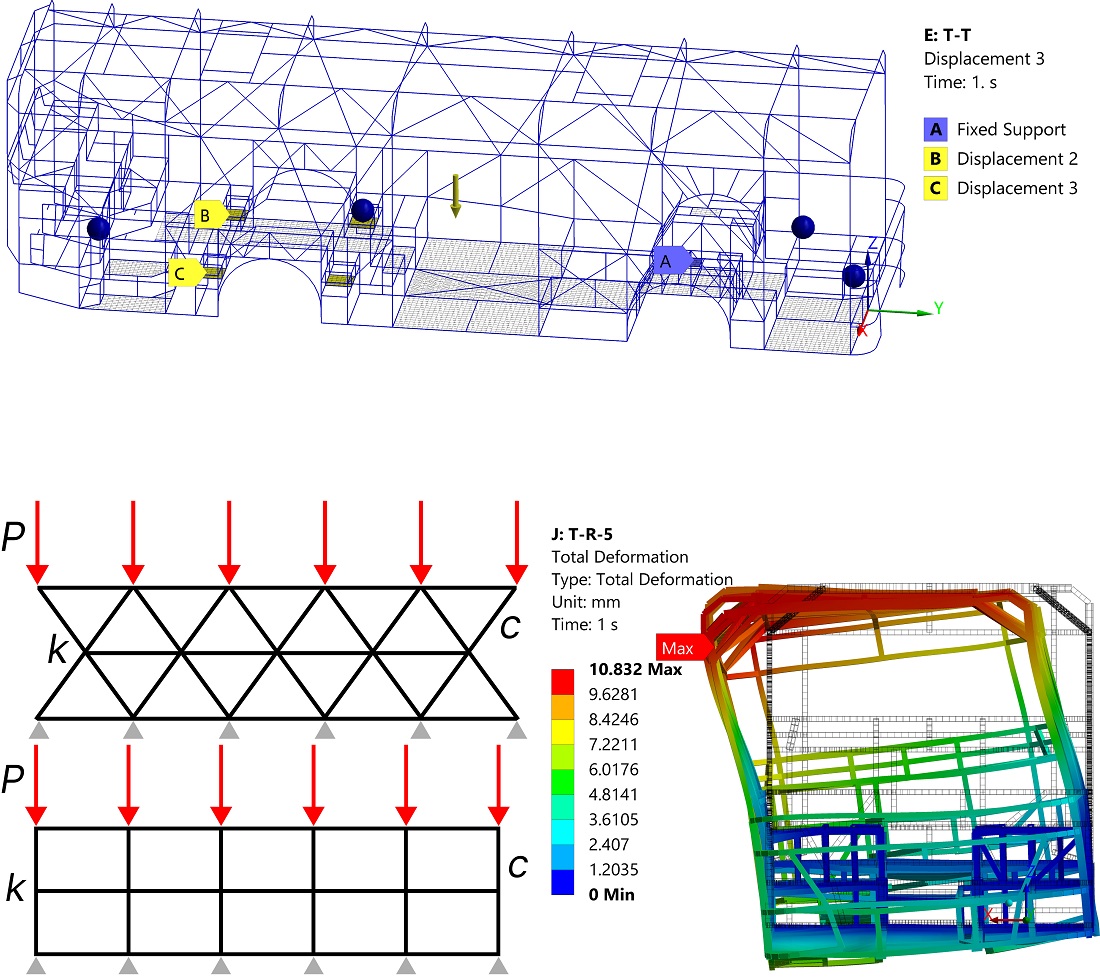

The object of this study is a spatial model of the body frame for the Ukrautobusprom 4289 city bus, which is subject to structural optimization of the sidewalls in order to strengthen them because of the increase in equipped weight. The reason for loading is the need to install batteries on the roof, which is the only possible location, given the low-entry layout. Electrification of city buses is associated with the inevitable regulated reduction of CO2 emissions by 30 % by 2030 (Euro 7) and complete decarbonization by 2050. Making up 30–40 % of the total cost of the bus, the body requires preservation when re-equipping diesel city buses for electric traction. Electrification automatically imposes UNECE R100 requirements for the absorption of 5.5 and 6g accelerations by the battery pack together with the body. To solve the problem, a transition from classic rectangular to triangular inter-window openings of the sidewalls has been proposed. An analytical methodology for simulating full-scale tests is proposed, close to real physical tests. Owing to the higher rigidity of triangular structures, a reduction in maximum stresses by 2.85 and 16.75 % was achieved under the static torsion and bending modes while the structure was maintained within the yield strength of steel σy=252 MPa. Maximum deformations decreased by 28.71 % in bending and by 50.77 % in torsion. Stresses under R100 conditions decreased by 18.52 and 16.07 % under the 6.6g and 5g modes, respectively. Deformations in the latter case decreased by 46.09 % and amounted to 10.83 mm only. Owing to the proposed approach, it was possible to achieve unification of the body for any type of drive: diesel, hybrid, or electric. Given sufficient technological feasibility of bus body production, this solution could be used in practice

References

- Holenko, K., Dykha, O., Koda, E., Kernytskyy, I., Royko, Y., Horbay, O. et al. (2024). Validation of Frontal Crashworthiness Simulation for Low-Entry Type Bus Body According to UNECE R29 Requirements. Applied Sciences, 14 (13), 5595. https://doi.org/10.3390/app14135595

- Holenko, K., Dykha, O., Koda, E., Kernytskyy, I., Horbay, O., Royko, Y. et al. (2024). Structure and Strength Optimization of the Bogdan ERCV27 Electric Garbage Truck Spatial Frame Under Static Loading. Applied Sciences, 14 (23), 11012. https://doi.org/10.3390/app142311012

- Holenko, K., Koda, E., Kernytskyy, I., Babak, O., Horbay, O., Popovych, V. et al. (2023). Evaluation of Accelerator Pedal Strength under Critical Loads Using the Finite Element Method. Applied Sciences, 13 (11), 6684. https://doi.org/10.3390/app13116684

- Kehoe, P., Jafroudi, N., Oubahou, R. A., Toma, E. (2024). Experimental Testing for the Validation of a Multi-body Dynamics Model for a Novel Electric Bus. Advances in Dynamics of Vehicles on Roads and Tracks III, 664–670. https://doi.org/10.1007/978-3-031-66968-2_65

- Yang, X., Tian, D. (2024). Design Optimization of a Lightweight Electric Bus Body Frame Orienting the Static Performance and Side-Impact Safety. SAE Technical Paper Series. https://doi.org/10.4271/2024-01-2461

- Wang, D., Xie, C., Liu, Y., Xu, W., Chen, Q. (2020). Multi-objective Collaborative Optimization for the Lightweight Design of an Electric Bus Body Frame. Automotive Innovation, 3 (3), 250–259. https://doi.org/10.1007/s42154-020-00105-1

- Hong, H. C., Hong, J. Y., D’Apolito, L., Xin, Q. F. (2024). Optimizing Lightweight and Rollover Safety of Bus Superstructure with Multi-Objective Evolutionary Algorithm. International Journal of Automotive Technology, 25 (4), 731–743. https://doi.org/10.1007/s12239-024-00072-0

- Teng, T.-L., Liang, C.-C., Chu, H.-M. (2022). Development and Analysis of Bus with Composite-Material-Reinforced Frames. International Journal of Automotive Technology, 23 (5), 1229–1237. https://doi.org/10.1007/s12239-022-0108-9

- Yang, X., Liu, B. (2024). Frontal Crash Oriented Robust Optimization of the Electric Bus Body Frame Considering Tolerance Design. SAE Technical Paper Series. https://doi.org/10.4271/2024-01-2459

- Jiang, W., Zhang, Y., Liu, J., Zhang, D., Yan, Y., Song, C. (2023). Multi-objective optimization design for steel-aluminum lightweight body of pure electric bus based on RBF model and genetic algorithm. Electronic Research Archive, 31 (4), 1982–1997. https://doi.org/10.3934/era.2023102

- Fu, C. L., Bai, Y. C., Lin, C., Wang, W. W. (2019). Design optimization of a newly developed aluminum-steel multi-material electric bus body structure. Structural and Multidisciplinary Optimization, 60 (5), 2177–2187. https://doi.org/10.1007/s00158-019-02292-w

- Gan, J., Zou, L., Yang, X., Liu, J. (2023). Optimization of the Bolted T-Joint of an Electric Bus Body Frame Considering the Fatigue Performance. SAE Technical Paper Series. https://doi.org/10.4271/2023-01-0028

- Wang, D., Mao, A., Niu, Y., Wei, J., Shi, X. (2017). Lightweight Multi-objective Optimization Design for Body Frame of Pure Electric Large Bus Based on Topology Optimization. China Journal of Highway and Transport, 30 (2), 136–143. https://zgglxb.chd.edu.cn/EN/Y2017/V30/I2/136

- Fan, D., Yang, X., Song, Y., Zhang, S. (2023). Robust Optimization of an Electric Bus Body Frame Based on the Mesh Morphing Technology. SAE Technical Paper Series. https://doi.org/10.4271/2023-01-0033

- Schmauder, N., Malzacher, G., Fritsche, M., Burkat, M., König, J., Boese, B. (2024). High potential: lightweight optimised structural design of car bodies for railway vehicles with alternative drive systems. Discover Mechanical Engineering, 3 (1). https://doi.org/10.1007/s44245-024-00040-z

- Yang, R., Zhang, W., Li, S., Xu, M., Huang, W., Qin, Z. (2023). Finite Element Analysis and Optimization of Hydrogen Fuel Cell City Bus Body Frame Structure. Applied Sciences, 13 (19), 10964. https://doi.org/10.3390/app131910964

- Liu, Y., Liu, C., Tan, J., He, Y., Li, F., Zhang, T. (2024). Optimization and Structural Analysis of Automotive Battery Packs Using ANSYS. Symmetry, 16 (11), 1464. https://doi.org/10.3390/sym16111464

- Liu, F., Xu, Y., Li, M., Guo, J., Han, B. (2022). Optimization of automotive battery pack casing based on equilibrium response surface model and multi-objective particle swarm algorithm. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 237 (6), 1183–1194. https://doi.org/10.1177/09544070221104858

- Wang, K., Shi, P., Zhang, Z. (2023). Finite element modeling of electric vehicle power battery pack and its influence analysis and test research at body-in-white stage. Journal of Vibroengineering, 25 (7), 1353–1368. https://doi.org/10.21595/jve.2023.23260

- Bijwe, V. B., Mahajan, R., Vaidya, R., Patel, K., Hiwale, D., Walke, A. A. (2024). Simulation Methodology Development for Vibration Test of Bus Body Structure Code AIS-153:2018. SAE Technical Paper Series. https://doi.org/10.4271/2024-26-0249

- Pravilonis, T., Sokolovskij, E., Kilikevičius, A., Matijošius, J., Kilikevičienė, K. (2020). The Usage of Alternative Materials to Optimize Bus Frame Structure. Symmetry, 12 (6), 1010. https://doi.org/10.3390/sym12061010

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Kostyantyn Holenko, Oleksandr Dykha, Maksym Dykha, Volodymyr Dytyniuk, Orest Horbay, Yurii Voichyshyn, Lybomyr Krainyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.