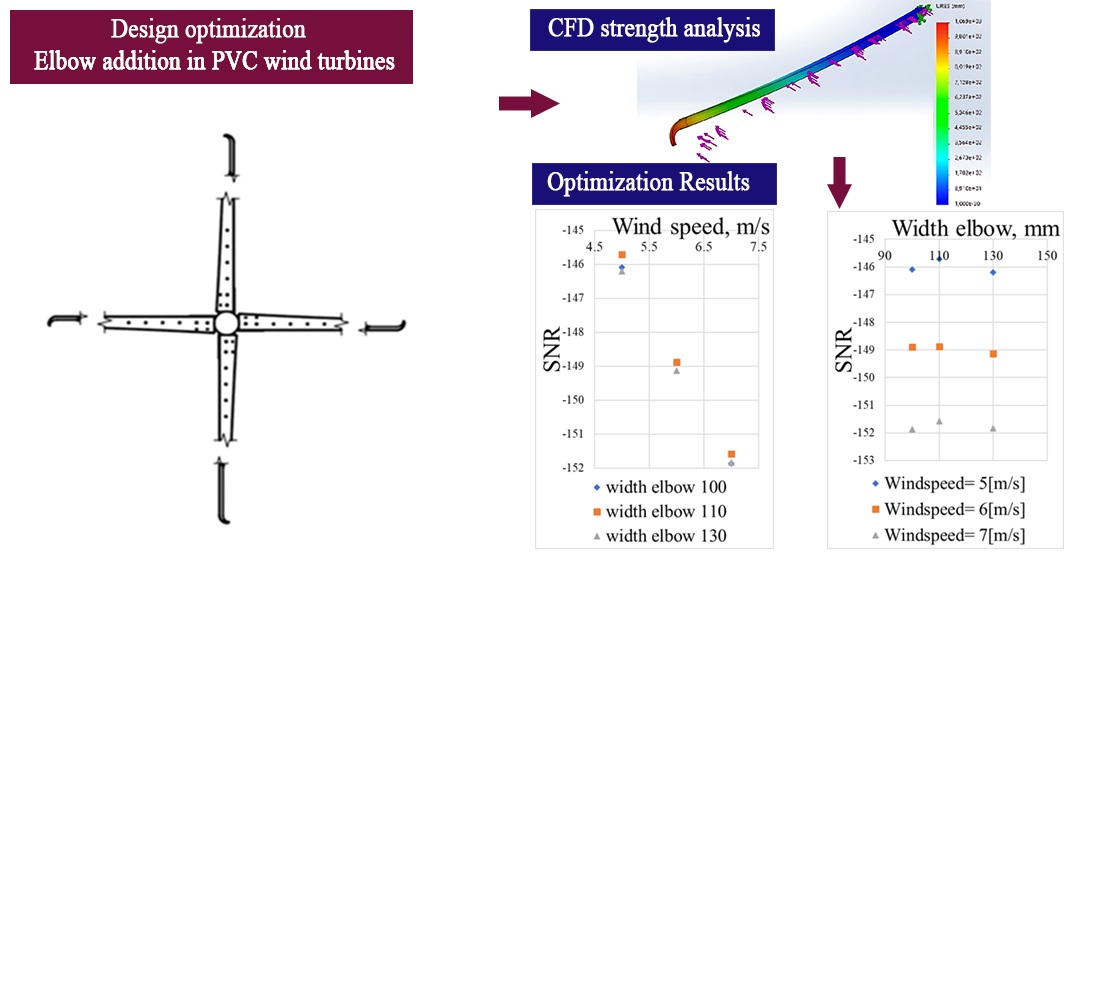

Optimization design of wind turbine propeller using PVC pipe material with elbow tip accessories

DOI:

https://doi.org/10.15587/1729-4061.2025.322426Keywords:

wind turbine, PVC pipe propeller, optimization, stress analysis, CFD simulationAbstract

PVC or Polyvinyl Chloride is a thermoplastic polymer, cheap, and can be used to make pipes and fittings. PVC pipes can be used to make low-power wind turbine blades. PVC pipes have good mechanical properties, including impact strength, high flexibility, vibration resistance, and hydrostatic pressure. To modify the pipe into a wind turbine blade that is strong against loads and has torsional resistance, an efficient design and manufacturing method is needed. In the blade design, an aerodynamic analysis is also carried out to obtain maximum energy from the wind turbine which is the result of the blade design performance. The goal is to find a way to build a turbine blade using PVC pipe and the best aerodynamic behavior of the fluid around the turbine rotor. This research is based on the CFD simulation method and experimental studies using a wind tunnel. Based on the results of the ANSYS CFD simulation at the elbow end of the PVC pipe turbine blade with an angle of attack of 15° and 30°, it can increase the torque by about 200 % compared to without the elbow end. CFD simulation was conducted to test the load on the PVC pipe blade with wind speeds of 5 m/s, 6 m/s, and 7 m/s, and angle tip widths of 100 mm, 110 mm, and 130 mm. The torque generated by the turbine is influenced by the width of the elbow tip, where the maximum torque is achieved by an elbow tip width of 110 mm. Based on the optimization results, the turbine can produce the best torque performance with the lowest stress generated from the load. The results of the von Mises stress analysis show that the stress that occurs on the turbine blade is the lowest, making it the safest and most reliable design. The results of the torque analysis show that the addition of an elbow tip can increase the torque on the turbine blade

References

- Owusu, P. A., Asumadu-Sarkodie, S. (2016). A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Engineering, 3 (1), 1167990. https://doi.org/10.1080/23311916.2016.1167990

- Rathod, V., Kamdi, S. Y. (2014). Design & Fabrication of PVC Bladed Inexpensive Wind Turbine. IOSR Journal of Mechanical and Civil Engineering, 11 (4), 114–119. https://doi.org/10.9790/1684-1142114119

- Adiwidodo, S., Wahyudi, B., Yudiyanto, E., Subagiyo, S., Hartono, M., Baananto, F. (2020). Simulation study of Savonius tandem blade wind turbine using an adjustable deflector. IOP Conference Series: Materials Science and Engineering, 732 (1), 012093. https://doi.org/10.1088/1757-899x/732/1/012093

- Duquette, M. M., Visser, K. D. (2003). Numerical Implications of Solidity and Blade Number on Rotor Performance of Horizontal-Axis Wind Turbines. Journal of Solar Energy Engineering, 125 (4), 425–432. https://doi.org/10.1115/1.1629751

- Thumthae, C. (2015). Optimum Blade Profiles for a Variable-Speed Wind Turbine in Low Wind Area. Energy Procedia, 75, 651–657. https://doi.org/10.1016/j.egypro.2015.07.478

- Maheri, A. (2020). Multiobjective optimisation and integrated design of wind turbine blades using WTBM-ANSYS for high fidelity structural analysis. Renewable Energy, 145, 814–834. https://doi.org/10.1016/j.renene.2019.06.013

- Balijepalli, R., Chandramohan, V. P., Kirankumar, K. (2018). Optimized design and performance parameters for wind turbine blades of a solar updraft tower (SUT) plant using theories of Schmitz and aerodynamics forces. Sustainable Energy Technologies and Assessments, 30, 192–200. https://doi.org/10.1016/j.seta.2018.10.001

- Liu, Z., Wang, X., Kang, S. (2014). Stochastic performance evaluation of horizontal axis wind turbine blades using non-deterministic CFD simulations. Energy, 73, 126–136. https://doi.org/10.1016/j.energy.2014.05.107

- Cekus, D., Gnatowska, R., Kwiatoń, P., Šofer, M. (2019). Simulation research of a wind turbine using SolidWorks software. Journal of Physics: Conference Series, 1398 (1), 012001. https://doi.org/10.1088/1742-6596/1398/1/012001

- Ceruti, A. (2018). Meta-heuristic multidisciplinary design optimization of wind turbine blades obtained from circular pipes. Engineering with Computers, 35 (2), 363–379. https://doi.org/10.1007/s00366-018-0604-8 -8

- Rathod, V. K., Kamdi, S. Y. (2014). Design of PVC Bladed Horizontal Axis Wind Turbine for Low Wind Speed Region. International Journal of Engineering Research and Application, 4 (7), 139–143. Available at: https://www.academia.edu/8292369/Design_of_PVC_Bladed_Horizontal_Axis_Wind_Turbine_for_Low_Wind_Speed_Region

- Herr, S. et al. (2020). Pat. No. BRPI0901809B1. Propeller Blade for a Wind Turbine. Available at: https://patents.google.com/patent/BRPI0901809B1/en?oq=BRPI0901809B1

- Liang S. et al. (2015). Pat. No. CN101592122B. Wind turbine blade with twisted tip. Available at: https://patents.google.com/patent/CN101592122B/en?oq=Liang+S.+et.al.+2015.+Wind+turbine+blade+with+twisted+tip.+Patent+No.+CN101592122B

- Meldgaard, C. (2016). Pat. No. EP2034178A3. Windturbinenschaufel mit lenkbaren Blättern. Available at: https://patents.google.com/patent/EP2034178A3/de?oq=EP2034178A3

- Wahyudi, B., Faizin, A., Wicaksono, H. (2023). Pat. Sederhana IDS000005963.

- Li, Y., Castro, A. M., Sinokrot, T., Prescott, W., Carrica, P. M. (2015). Coupled multi-body dynamics and CFD for wind turbine simulation including explicit wind turbulence. Renewable Energy, 76, 338–361. https://doi.org/10.1016/j.renene.2014.11.014

- Abdulqadir, S. A., Iacovides, H., Nasser, A. (2017). The physical modelling and aerodynamics of turbulent flows around horizontal axis wind turbines. Energy, 119, 767–799. https://doi.org/10.1016/j.energy.2016.11.060

- Wahyudi, B., Faizin, A., Setiawan, A., Susilo, S. H., Wicaksono, H. (2022). Simulation study of horizontal axis wind turbine using PVC pipe propeller with elbow tip. EUREKA: Physics and Engineering, 5, 67–76. https://doi.org/10.21303/2461-4262.2022.002550

- Kennedy, I. R., Hodzic, M., Crossan, A. N., Acharige, N., Runcie, J. (2021). A New Theory for Estimating Maximum Power from Wind Turbines: A Fundamental Newtonian Approach. arXiv. https://doi.org/10.48550/arXiv.2110.15117

- Piggott, H. (2011). Wind Power Workshop. Centre for Alternative Technology.

- Mohammadi, M., Mohammadi, A., Mohammadi, M., Minaei, H. N. (2015). Optimization of Small Scale Wind Turbine Blades for Low Speed Conditions. Journal of Clean Energy Technologies, 4 (2), 140–143. https://doi.org/10.7763/jocet.2016.v4.268

- Arpino, F., Cortellessa, G., Dell’Isola, M., Scungio, M., Focanti, V., Profili, M., Rotondi, M. (2017). CFD simulations of power coefficients for an innovative Darrieus style vertical axis wind turbine with auxiliary straight blades. Journal of Physics: Conference Series, 923, 012036. https://doi.org/10.1088/1742-6596/923/1/012036

- Carvalho, A., Gonzalez, M. C., Costa, P., Martins, A. (2009). Issues on performance of wind systems derived from exploitation data. 2009 35th Annual Conference of IEEE Industrial Electronics, 3599–3604. https://doi.org/10.1109/iecon.2009.5415151

- Datkhile, M., Tapre, P. C., Veeresh, C. (2016). A Comparative Study of Constant Speed and Variable Speed Wind Energy Conversion Systems. GRD Journal for Engineering, 1 (10). Available at: https://journals.indexcopernicus.com/api/file/viewByFileId/150161

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Akhmad Faizin, Bagus Wahyudi, Hangga Wicaksono, Satworo Adiwidodo, Mohammad Sukri Mustapa

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.