Розробка технологічних параметрів стабілізації пористої структури кремнебетону

DOI:

https://doi.org/10.15587/1729-4061.2025.322462Ключові слова:

газокремнебетон, структура, пластична міцність, реологія, вапно, алюмінієвий порошок, в’яжуче, автоклавАнотація

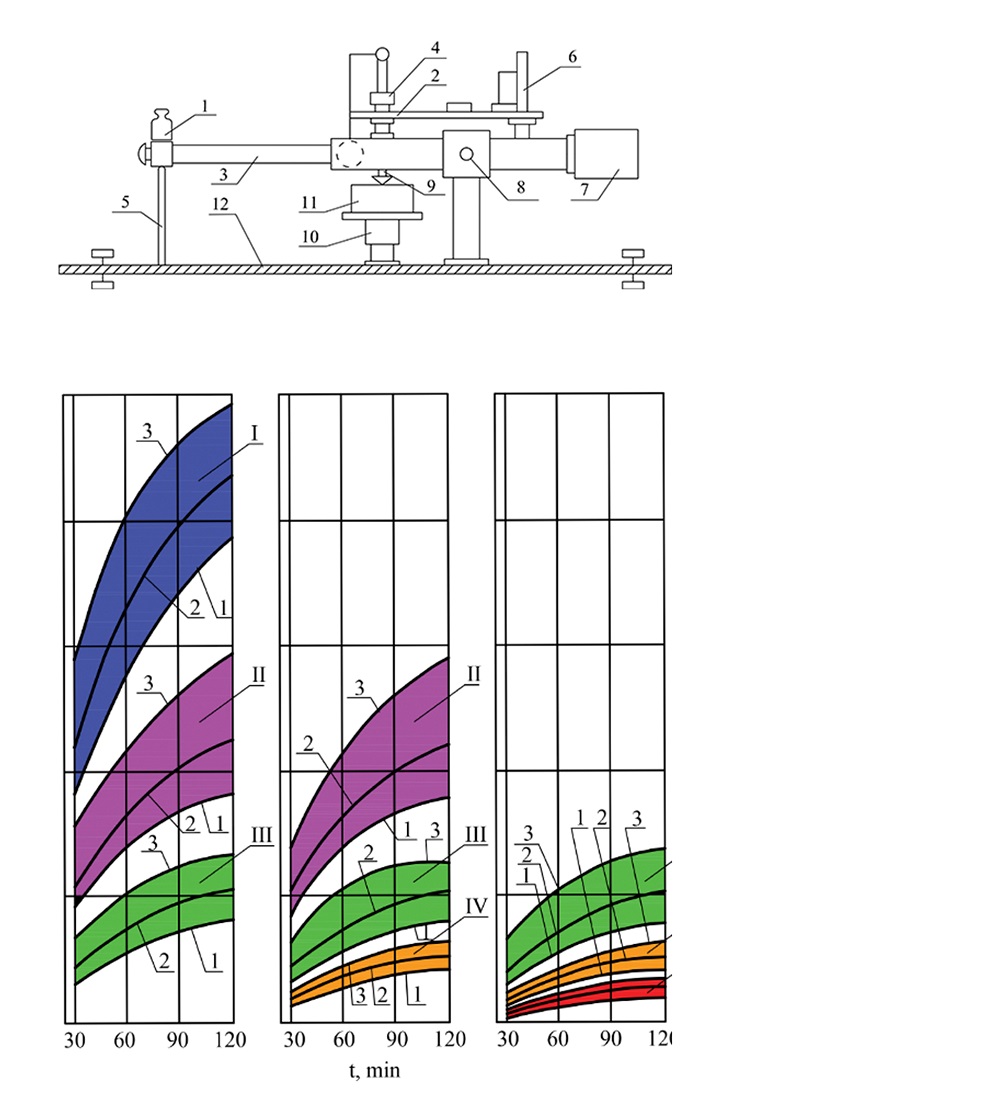

Об’єктом дослідження є газокремнебетонна суміш. Вирішується проблема синхронізації процесів пороутворення та зростання пластичної міцності, що є обов’язковою умовою забезпечення стабільності пористої структури. Експериментально визначено оптимальні значення водотвердого відношення (0,3–0,35), кількості меленого негашеного вапна (до 1,5 %) та алюмінієвого порошку (0,04–0,1 %), які забезпечують формування стійкої пористої структури з мінімальною пластичною міцністю 10,0 кПа, достатньої для проведення автоклавної обробки. Формування сталої пористої структури забезпечується синтезом трикальцієвого гідроалюмінату, який є продуктом реакції між негашеним вапном та алюмінієвим порошком. Трикальцієвий гідроалюмінат відомий своєю швидкою реакційною здатністю, що забезпечує прискорений набір міцності. Це дозволяє уникнути осідання матеріалу та стабілізувати пористу структури до початку автоклавної обробки. Отримані результати показують, що підвищення кількості алюмінієвого порошку позитивно впливає на структурну міцність суміші, тоді як перевищення допустимого рівня меленого негашеного вапна (1,5 %) призводить до зниження міцності кінцевого продукту. Таким чином вирішена важлива компромісна задача: синхронізація процесів пороутворення кремнебетонної суміші та зросту пластичної міцності у часі в співвідношеннях компонентів, які не перешкоджають твердінню кремнебетонної суміші в процесі автоклавної обробки. Використання меленого негашеного вапна та алюмінієвого порошку дозволяє досягти високих стандартів екологічності завдяки зниженню обсягів традиційних ресурсів, у виробничих процесах. Таким чином, результати дослідження створюють наукову основу для впровадження у виробництво нових типів екологічних будівельних матеріалів з поліпшеними характеристиками

Посилання

- Shadhar, A. K., Mahmood, B. B., Abboud Abdulhassan, A., Mahjoob, A. M. R., Shamkhi, M. S. (2023). Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq. Open Engineering, 13 (1). https://doi.org/10.1515/eng-2022-0486

- Korkmaz, A. V., Hacıfazlıoğlu, H. (2023). An alternative raw material for Portland cement clinker preparation: Meta-schist. https://doi.org/10.21203/rs.3.rs-2578354/v1

- Abdul-Wahab, S. A., Al-Dhamri, H., Ram, G., Chatterjee, V. P. (2020). An overview of alternative raw materials used in cement and clinker manufacturing. International Journal of Sustainable Engineering, 14 (4), 743–760. https://doi.org/10.1080/19397038.2020.1822949

- Anand, P., Sinha, A. K., Rajhans, P. (2023). Study on Mechanical and Durability Properties of Aerated Concrete Block Containing Construction and Demolition Waste with Aluminium Stearate Powder Along with Alkaline Solution and Considering Accelerated Curing Tank. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 48 (2), 797–823. https://doi.org/10.1007/s40996-023-01222-7

- Freidin, C. (2001). Stability of silica concrete based on quartz bond in water, sodium sulphate, and sulphuric acid solutions. British Ceramic Transactions, 100 (3), 129–133. https://doi.org/10.1179/096797801681341

- Cui, H., Tang, F., Li, B., Lin, Z. (2023). Microstructure and Corrosion Resistance of Quartz Sand-Modified Enamel-Coated Steel Plates. Coatings, 13 (10), 1704. https://doi.org/10.3390/coatings13101704

- Pączkowski, P., Głogowska, K. (2024). Preparation and Characterization of Quartz-Reinforced Hybrid Composites Based on Unsaturated Polyester Resin from Post-Consumer PET Recyclate. Materials, 17 (5), 1116. https://doi.org/10.3390/ma17051116

- Babalu, R., Sunil, P. (2019). Chemical Resistance of Nano Silica Added Concrete. International Journal of Innovative Technology and Exploring Engineering, 8 (12), 3472–3476. https://doi.org/10.35940/ijitee.l2607.1081219

- Kantarcı, F., Türkmen, İ., Ekinci, E. (2023). Enhancing acid resistance of geopolymer concrete composites by utilising styrene-butadiene latex, nano-silica and micro-silica powder. European Journal of Environmental and Civil Engineering, 27 (15), 4416–4434. https://doi.org/10.1080/19648189.2023.2191675

- Pang, B., Jia, Y., Pang, S. D., Zhang, Y., Du, H., Geng, G. et al. (2021). Research on the toughening mechanism of modified nano-silica and silane molecular cages in the multi-scale microfracture of cement-epoxy composite. Cement and Concrete Composites, 119, 104027. https://doi.org/10.1016/j.cemconcomp.2021.104027

- Badashah Nadaf, N. (2024). Review on Aerated Lightweight Concrete Challenges and Application. International Journal of Innovative Science and Research Technology (IJISRT), 9 (4), 1540–1543. https://doi.org/10.38124/ijisrt/ijisrt24apr1703

- Michelini, E., Ferretti, D., Miccoli, L., Parisi, F. (2023). Autoclaved aerated concrete masonry for energy efficient buildings: State of the art and future developments. Construction and Building Materials, 402, 132996. https://doi.org/10.1016/j.conbuildmat.2023.132996

- Islam, M. M., Rashid, M. H., Muntasir, M. A. (2022). Influence of Aluminium and Autoclaving Temperature on the Properties of Autoclaved Aerated Concrete. Journal of Engineering Science, 12 (3), 11–17. https://doi.org/10.3329/jes.v12i3.57475

- Adler, Yu. P., Markova, E. V., Granovskiy, Yu. V. (1976). Planirovanie eksperimenta pri poiske optimal'nyh usloviy. Moscow: Nauka, 140.

- Lyashenko, T. V., Voznesensky, V. A. (2017). Composition-Process Fields Methodology in Computational Building Materials Science. Оdesa: Astroprint, 168.

- Krylov, E., Martynov, V., Mykolaiets, M., Martynova, O., Vietokh, O. (2019). Influence of modification of the solid component on the properties of non-autoclaved aerated concrete. Eastern-European Journal of Enterprise Technologies, 3 (6 (99)), 53–59. https://doi.org/10.15587/1729-4061.2019.171012

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Volodymyr Martynov, Anatoliy Gara , Alexander Gara

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.