Determining the effect of the amount of polypropylene fiber and plasticizer on the strength and abrasion resistance of concretes for rigid pavement

DOI:

https://doi.org/10.15587/1729-4061.2025.322590Keywords:

polypropylene fiber, plasticizer, rigid pavement, concrete strength, concrete abrasion resistance, experimental and statistical modelingAbstract

The object of this study is concretes and fiber-reinforced concretes for rigid pavements with polypropylene fiber and lignosulphonate type plasticizer. The task addressed is obtaining concrete with increased strength and wear resistance. Three compositions factors were varied in the experiment conducted according to the D-optimal plan: the amount of cement (300–380 kg/m3), plasticizer based on lignosulfonates (0.6–1.0 %), polypropylene fiber with a fiber length 39 mm (0–3 kg/m3). All concrete mixtures had equal mobility S1.

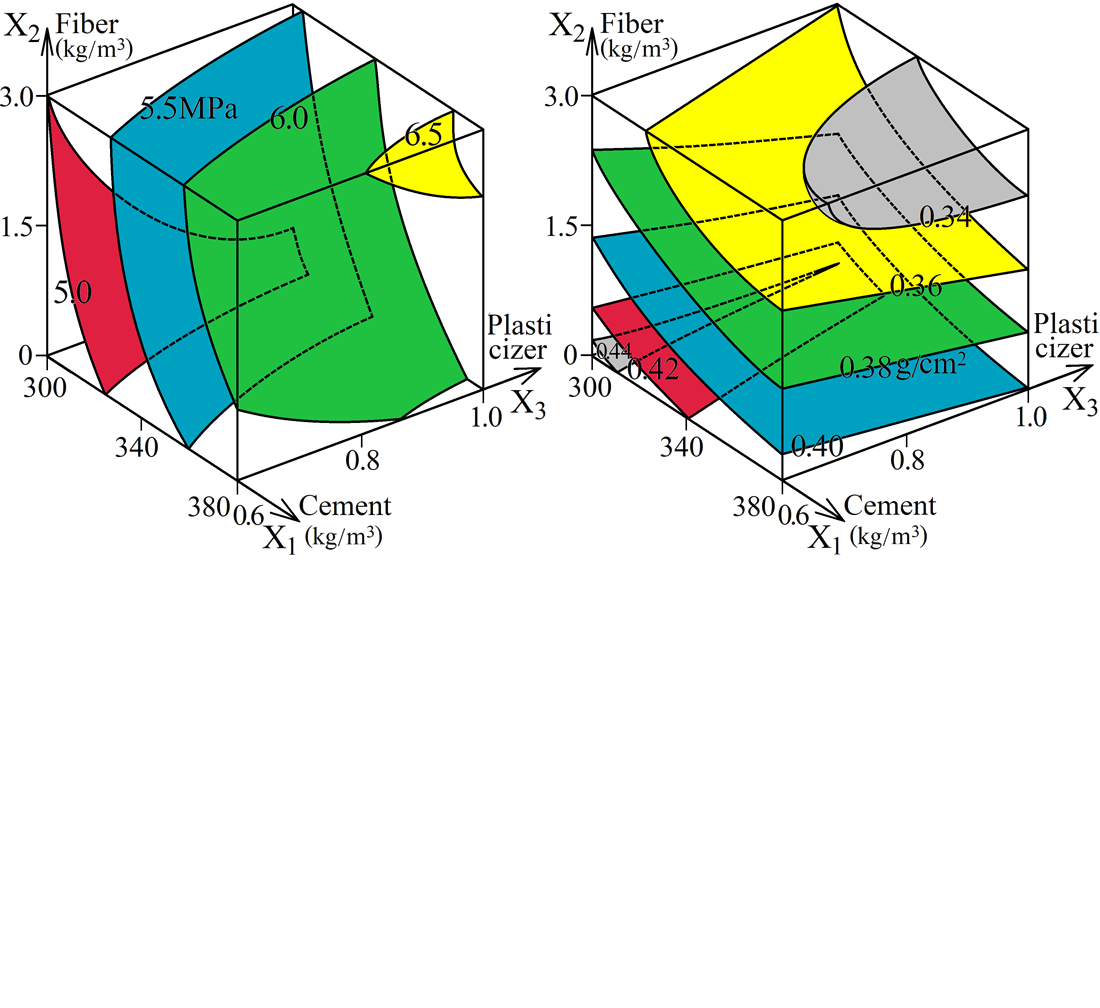

A set of experimental and statistical models was calculated. It was found that with an increase in the amount of plasticizer, the W/C ratio of the mixture decreases by 12–15 %, and the introduction of fiber has a negligible effect on W/C. Due to the use of fiber, the compressive strength of concrete at the design age increases by approximately 3.5 MPa, the early compressive strength practically does not change, the flexural strength increases by 0.5–0.6 MPa, and the abrasion resistance decreases by 0.07–0.08 g/cm2 (17–19 %). The most noticeable changes in these properties occur already with the introduction of fibers in the amount of 2–2.5 kg/m3. Increasing the amount of cement improves the strength and wear resistance of concrete, as well as the efficiency of using dispersed reinforcement.

When the amount of plasticizer is increased from 0.6 to 0.9 %, the compressive strength of concrete at the age of 3 days increases by approximately 2 MPa; at the design age, its strength increases by approximately 5 MPa, the flexural strength increases to a limited extent while the abrasion of concrete decreases (wear resistance increases).

Due to dispersed reinforcement and the use of a rational amount of plasticizer, concretes of rigid pavements with the required strength and increased wear resistance required for a given road category with reduced binder consumption were obtained, which could be used in practice

References

- Radovskiy, B., Nahaichuk, V. (2020). World experience and modern approaches to the use of cement concrete pavement. Dorogi i Mosti, 21, 188–200. https://doi.org/10.36100/dorogimosti2020.21.188

- DBN V.2.3-4:2015. Highways. Part I. Design. Part II. Building.

- Murph, D., Liu, J., Liu, J. (2022). Designs of Abrasion Resistant and Durable Concrete Pavements Made with SCMs for Cold Climates. Journal of Transportation Engineering, Part B: Pavements, 148 (2). https://doi.org/10.1061/jpeodx.0000360

- Al Harki, B. Q. K., Al Jawahery, M. S., Abdulmawjoud, A. A. (2022). Hybrid Steel Fiber of Rigid Pavements: A 3D Finite Element and Parametric Analysis. Coatings, 12 (10), 1478. https://doi.org/10.3390/coatings12101478

- Salman, A., Hassan, A., Galal, S., Hassan, A. (2024). Effect of Carbon Nanotubes and Steel Fibers on the Rigid Pavement Reinforced with Steel Bars and GFRP Bars. Proceedings of the ICSDI 2024 Volume 1, 89–97. https://doi.org/10.1007/978-981-97-8712-8_12

- Kos, Ž., Kroviakov, S., Kryzhanovskyi, V., Grynyova, I. (2022). Research of Strength, Frost Resistance, Abrasion Resistance and Shrinkage of Steel Fiber Concrete for Rigid Highways and Airfields Pavement Repair. Applied Sciences, 12 (3), 1174. https://doi.org/10.3390/app12031174

- Spyridis, P., Mellios, N. (2022). Tensile Performance of Headed Anchors in Steel Fiber Reinforced and Conventional Concrete in Uncracked and Cracked State. Materials, 15 (5), 1886. https://doi.org/10.3390/ma15051886

- Surianinov, M., Andronov, V., Otrosh, Y., Makovkina, T., Vasiukov, S. (2020). Concrete and Fiber Concrete Impact Strength. Materials Science Forum, 1006, 101–106. https://doi.org/10.4028/www.scientific.net/msf.1006.101

- Sikandar, A., Ali, M. (2023). Composition of Engineered Cementitious Composite with Local Materials, Composite Properties and Its Utilization for Structures in Developing Countries. IOCBD 2023, 16. https://doi.org/10.3390/iocbd2023-15179

- Santhosh, J. C., Samal, S. R., Ganesh, V. N., Pavani, D., Sridhar, R. S. (2022). Experimental Investigation on the Effect of Polypropylene Fibers with Respect to the Fatigue Behavior of Rigid Pavement. Recent Developments in Sustainable Infrastructure (ICRDSI-2020) – GEO-TRA-ENV-WRM, 383–395. https://doi.org/10.1007/978-981-16-7509-6_31

- Julon, L., Zarate, B., Silvera, M., Campos, F., Silvera, M., Palacios-Alonso, D. (2023). Evaluation of the influence of polypropylene fiber on the flexural strength of rigid pavements. Proceedings of the 21th LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2023): “Leadership in Education and Innovation in Engineering in the Framework of Global Transformations: Integration and Alliances for Integral Development.” https://doi.org/10.18687/laccei2023.1.1.491

- Spyra, J., Mellios, N., Borttscheller, M., Spyridis, P. (2024). Influence of Polymer Fibre Reinforcement on Concrete Anchor Breakout Failure Capacity. Polymers, 16 (15), 2203. https://doi.org/10.3390/polym16152203

- Fawzi, R. Q., Awad, H. K. (2023). The Influence of Polypropylene Fiber and Silica Fume on the Mechanical Properties of No-Fine Concrete with Recycled Aggregate. E3S Web of Conferences, 427, 02002. https://doi.org/10.1051/e3sconf/202342702002

- Sanytsky, M., Kropyvnytska, T., Vakhula, O., Bobetsky, Y. (2023). Nanomodified Ultra High-Performance Fiber Reinforced Cementitious Composites with Enhanced Operational Characteristics. Proceedings of CEE 2023, 362–371. https://doi.org/10.1007/978-3-031-44955-0_36

- Kryzhanovskyi, V., Umbach, C., Orlowsky, J., Middendorf, B., Auras, M., Grillich, P. (2024). Denkmalkonforme Instandsetzung der Beton‐Glas‐Fenster der St.‐Mauritius‐Kirche. Bautechnik, 101 (5), 299–308. https://doi.org/10.1002/bate.202300117

- Ubair Ul Islam, S., Chopra, A., Tiwary, A. K. (2023). Finite Element Analysis of High-Strength Concrete Pavement Made With The Addition Of Fibres. IOP Conference Series: Earth and Environmental Science, 1110 (1), 012025. https://doi.org/10.1088/1755-1315/1110/1/012025

- Volchuk, V. M., Kotov, M. A., Plakhtii, Y. G., Tymoshenko, O. A., Zinkevych, O. H. (2025). Investigation of the influence of the heterogeneous structure of concrete on its strength. Results in Materials, 25, 100659. https://doi.org/10.1016/j.rinma.2025.100659

- Kroviakov, S. O., Finohenov, O. I. (2024). Comparison of the effectiveness of superplasticizers in concretes for rigid pavement. Modern Construction and Architecture, 8, 65–71. https://doi.org/10.31650/2786-6696-2024-8-65-71

- Kos, Ž., Kroviakov, S., Kryzhanovskyi, V., Hedulian, D. (2022). Strength, Frost Resistance, and Resistance to Acid Attacks on Fiber-Reinforced Concrete for Industrial Floors and Road Pavements with Steel and Polypropylene Fibers. Materials, 15 (23), 8339. https://doi.org/10.3390/ma15238339

- Dvorkin, L., Ribakov, Y. (2012). Mathematical Experiments Planning in Concrete Technology. Nova Science Publishers, 172.

- Lyashenko, T. V., Voznesensky, V. A. (2017). Composition-Process Fields Methodology in Computational Building Materials Science. Оdesa: Astroprint, 168.

- BS EN 12350-2:2019. Testing fresh concrete - Slump test.

- BS EN 12390-3:2009. Testing hardened concrete - Compressive strength of test specimens.

- BS EN 12390-5:2009. Testing hardened concrete - Flexural strength of test specimens.

- ASTM C944/C944M-19. Standard test method for abrasion resistance of concrete or mortar surfaces by the rotating-cutter method. ASTM International. Available at: https://cdn.standards.iteh.ai/samples/104586/827f54b874d44a55a45b20b7b93c1690/ASTM-C944-C944M-19.pdf

- Dvorkin, L. Y., Zhytkovskyi, V. V., Bordiuzhenko, O. M., Marchuk, V. V., Rubtsova, Yu. O. (2021). Betony novoho pokolinnia. Rivne: Nats. un-t vod. hosp-va ta pryrodokorystuvannia, 316.

- Lin, C., Kanstad, T., Jacobsen, S., Ji, G. (2023). Bonding property between fiber and cementitious matrix: A critical review. Construction and Building Materials, 378, 131169. https://doi.org/10.1016/j.conbuildmat.2023.131169

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Sergii Kroviakov, Oleh Finohenov, Andrii Ihnatenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.