Evaluating the stiffness of a cast strip for protecting a preparatory mine working

DOI:

https://doi.org/10.15587/1729-4061.2025.324548Keywords:

preparatory working, cast strip, strength of the protective structure, deformation properties, occupational safetyAbstract

The object of this study is the deformation processes in a protective structure of the preparatory working, maintained in the excavated space of the excavation area. The task addressed was ensuring the stability of the preparatory working in a deep coal mine to improve the safety of miners and coal mining. The assessment of the strength of the cast strip for the protection of preparatory workings in excavation areas has been substantiated.

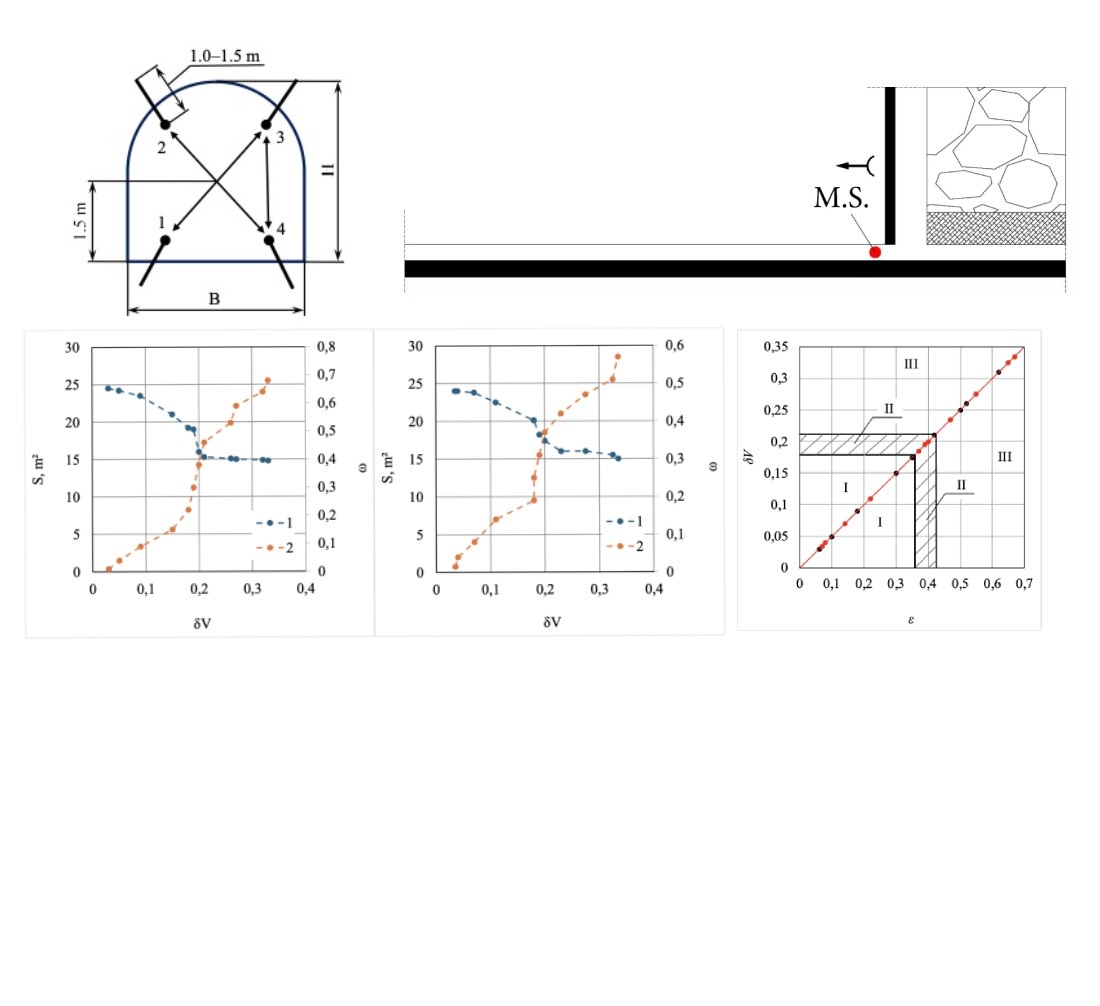

It was experimentally established that in the zone of active influence of mining pressure on the section 0<l<50 m behind the treatment face, there is an exponential dependence between the length of the working l (m) and the relative change in the volume dV of the protective structure. It characterizes the safe deformation resource of the cast strip. Within its limits, the process of gaining strength of the protective structure occurs. At dV<0.18 and the failure rate of the arched flexible support ω<0.2, the losses of the cross-sectional area of the working do not exceed 20 %. Under conditions when dV£0.22, the resistance of the protective structure increases, which makes it possible to limit the movement of lateral rocks on the contour of the working, ensuring its overall dimensions. In cases when dV>0.22, and 0.22<ω<0.68, the losses of the cross-sectional area are more than 40 %. At a distance of l>80 m behind the breakage face, the level of threat of roof collapses approaches a critical state, which is associated with an uncontrolled increase in lateral rock displacements due to the loss of strength of the cast strip.

The cast strip performs the functions of a supporting structure only in a certain range of physical, mechanical, and deformation properties.

The operational condition of the preparatory working is ensured within the deformation resource of the cast strip. After reaching the rated strength of the cast strip, its strength makes it possible to limit the movement of lateral rocks on the contour of the working and ensure its stability at a distance of l£80 m along the length of the excavation section

References

- Lozynskyi, V., Medianyk, V., Saik, P., Rysbekov, K., Demydov, M. (2020). Multivariance solutions for designing new levels of coal mines. Rudarsko-Geološko-Naftni Zbornik, 35 (2), 23–31. https://doi.org/10.17794/rgn.2020.2.3 3

- Salieiev, I. A., Bondarenko, V. I., Symanovych, H. A., Kovalevska, I. A. (2021). Development of a methodology for assessing the expediency of mine workings decommissioning based on the geomechanical factor. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 4, 10–16. https://doi.org/10.33271/nvngu/2021-4/010

- Yalanskiy, A. O., Slashchov, І. M., Slashchova, O. A., Seleznov, A. M., Arestov, V. V. (2018). Development of new auxiliary measures for protecting preparatory roadways by the cast strips. Geo-Technical Mechanics, 141, 3–17. https://doi.org/10.15407/geotm2018.141.003

- Wang, M., Wang, W., Xu, Y., Xie, G., Qin, J., Liu, H. et al. (2024). Study on the new layout pattern about the gob‐side entry under dynamic pressure and its surrounding rock stability control. Energy Science & Engineering, 12 (4), 1389–1410. https://doi.org/10.1002/ese3.1667

- Li, J., Yin, Z. Q., Li, Y., Li, C. M. (2019). Waste rock filling in fully mechanized coal mining for goaf-side entry retaining in thin coal seam. Arabian Journal of Geosciences, 12 (16). https://doi.org/10.1007/s12517-019-4650-3

- Tripolski, V. N., Buryak, N. A., Vojtovich, Т. G. (2018). Technological schemes for supporting reused gate roads by the cast strips. Geo-Technical Mechanics, 140, 13–22. https://doi.org/10.15407/geotm2018.03.013

- Bondarenko, V. I., Buzylo, V. I., Tabachenko, M. M., Medianyk, V. Yu. (2010). Heomekhanichni osnovy pidvyshchennia stiykosti pidhotovchykh vyrobok. Dnipropetrovsk: DVNZ «Natsionalnyi hirnychyi universytet», 408.

- Baysarov, L. V., Il'yatov, M. A., Demchenko, A. I. (2005). Geomehanika i tehnologiya podderzhaniya povtorno ispol'zuemyh gornyh vyrabotok. Dnepropetrovsk: ChP «Lira», 240.

- Bondarenko, V., Symanovych, H., Kovalevska, I., Chervatiuk, V. (2018). Maintenance of reusable mine workings during the augering mining of coal seams. E3S Web of Conferences, 60, 00001. https://doi.org/10.1051/e3sconf/20186000001

- Sergienko, V. N., Kozhushok, O. D., Prohorec, L. V. (2006). Kompleksnye issledovaniya deformacionno-prochnostnyh svoystv tverdeyuschih materialov dlya lityh polos. Geo-Technical Mechanics, 66, 96–102. Available at: http://geotm.dp.ua/attachments/article/7442/97-103.pdf

- Xie, S., Wang, E., Chen, D., Li, H., Jiang, Z., Yang, H. (2022). Stability analysis and control technology of gob-side entry retaining with double roadways by filling with high-water material in gently inclined coal seam. International Journal of Coal Science & Technology, 9 (1). https://doi.org/10.1007/s40789-022-00524-x

- Chang, Q., Tang, W., Xu, Y., Zhou, H. (2018). Research on the width of filling body in gob-side entry retaining with high-water materials. International Journal of Mining Science and Technology, 28 (3), 519–524. https://doi.org/10.1016/j.ijmst.2017.12.016

- Pu, S., Wu, G., Liu, Q., Wang, Y., Li, Q., Xiong, Y. (2022). Determination of Reasonable Width of Filling Body for Gob-Side Entry Retaining in Mining Face with Large Cutting Height. Geofluids, 2022, 1–11. https://doi.org/10.1155/2022/1774110

- Li, H., Zu, H., Zhang, K., Qian, J. (2022). Study on Filling Support Design and Ground Pressure Monitoring Scheme for Gob-Side Entry Retention by Roof Cutting and Pressure Relief in High-Gas Thin Coal Seam. International Journal of Environmental Research and Public Health, 19 (7), 3913. https://doi.org/10.3390/ijerph19073913

- Krus, Yu. O. (2000). Praktychnyi metod vyznachennia malotsyklovoi vtomlenosti betonu pry stysku. Beton i zhelezobeton v Ukrayne, 4, 10–17.

- Halimendik, Yu. M., Bruy, A. V. (2013). Vliyanie otpora krepi na sostoyanie vyrabotok pri ih povtornom ispol'zovanii. Naukovi pratsi UkrNDMI NAN Ukrainy, 13 (1), 31–44.

- Volkov, S., Boichenko, H. (2023). Assessment of the stability of mine haulage drift using statistical analysis of arch yielding support failure. Journal of Donetsk Mining Institute, 1, 16–28. https://doi.org/10.31474/1999-981x-2023-1-16-28

- Galvin, J. M. (2016). Ground Engineering - Principles and Practices for Underground Coal Mining. Springer International Publishing. https://doi.org/10.1007/978-3-319-25005-2

- Chepiga, D., Podkopaiev, S., Shashenko, O., Skobenko, O., Demchenko, O., Podkopayev, Y. et al. (2024). Determining the stability of roll-back stretches in steep layers when unloading a coal rock massif. Eastern-European Journal of Enterprise Technologies, 6 (1 (132)), 41–49. https://doi.org/10.15587/1729-4061.2024.314842

- Chepiga, D., Podkopaiev, S., Gogo, V., Shashenko, O., Skobenko, O., Demchenko, O., Podkopayev, Y. (2024). Dualistic effect of the deformation of protective structures made of broken rock in mine workings under static load. Mining of Mineral Deposits, 18 (2), 122–131. https://doi.org/10.33271/mining18.02.122

- Iordanov, I., Buleha, I., Bachurina, Y., Boichenko, H., Dovgal, V., Kayun, O., Kohtieva, O., Podkopayev, Y. (2021). Experimental research on the haulage drifts stability in steeply dipping seams. Mining of Mineral Deposits, 15 (4), 56–67. https://doi.org/10.33271/mining15.04.056

- Chatfield, C., Xing, H. (2019). The Analysis of Time Series. Chapman and Hall/CRC. https://doi.org/10.1201/9781351259446

- Dekking, F. M., Kraaikamp, C., Lopuhaä, H. P., Meester, L. E. (2005). A Modern Introduction to Probability and Statistics. In Springer Texts in Statistics. Springer London. https://doi.org/10.1007/1-84628-168-7

- Yeremenko, V. S., Kuts, Yu. V., Mokiychuk, V. M., Samoilichenko, O. V. (2013). Statystychnyi analiz danykh vymiriuvan. Kyiv: NAU, 320.

- Bakhrushyn, V. Ye. (2011). Metody analizu danykh. Zaporizhzhia: KPU, 268.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Daria Chepiga, Danylo Polii, Serhii Podkopaiev, Leonid Bachurin, Anatolii Bielikov, Ihor Slashchov, Yevgen Podkopayev, Olena Visyn, Valentyna Fedorchuk-Moroz

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.