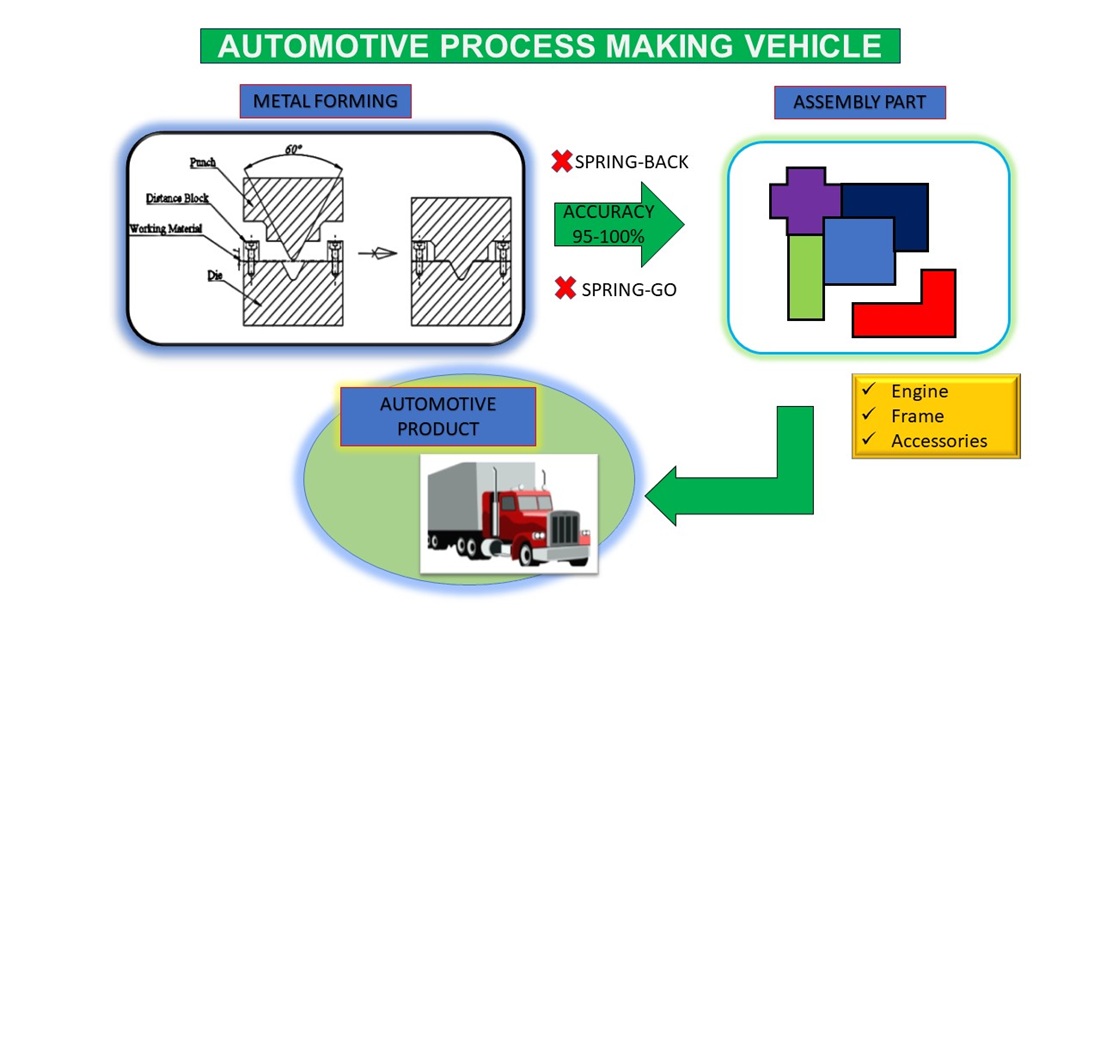

Assessment the effect of dies stamping process parameters on the performance of spring-back and spring-go defects in galvanized steel sheet materials

DOI:

https://doi.org/10.15587/1729-4061.2025.324951Keywords:

optimization, spring defect, dies stamping, manufacturing, punch angle, galvanized materialAbstract

Dies stamping is an important manufacturing process and widely applied in the modern industrial era. It provides convenience in the production process and rapid shape modification, especially for sheet materials. However, the quality occasionally experiences dimensional change which defined as spring back (SB) and spring go (SG). This study conducted an analysis related to the factors that contribute to the defect from dies stamping. The work used galvanized sheet and processed through V-bending using thickness, punch angle and pressure as parameter. The results show the deflection angle as the main indicator related to the defect. The highest SG occurs at thickness 1 mm with a punch angle/pressure of 60°/6×103 kg, causing the highest deflection angle of 4.45°. Oppositely, SB is observed with a maximum deflection of −2.2° when employing punch angle/pressure at 120°/9×103 kg for material with thickness 1.2 mm. One unique result is observed for the processing material at punch angle of 90°. The phenomenon of SB and SG are observed for different parameter. For example, thickness 1 mm experiences SB when using punch pressure 3×103 kg and 9×103 kg, while SG is observed under working pressure 6×103 kg. The microstructure observation shows a change in profile for the material after bending process, which is related to the mechanical deformation and when the deflection value approaches 0°, the microstructure shape profile becomes clearer which is related to plastic deformation. These results provide a reference for suitable dies stamping processing, potentially minimizing the defects and reduces the additional process that involve to repair the defect part. Thus, production quality is maintained optimally through the selection of ideal dies stamping parameters

References

- Ismail, I., Mulyanto, A. T., Rahman, R. A. (2022). Development of free water knock-out tank by using internal heat exchanger for heavy crude oil. EUREKA: Physics and Engineering, 4, 77–85. https://doi.org/10.21303/2461-4262.2022.002502

- Li, J., Tong, C., Zhang, R., Shi, Z., Lin, J. (2024). A data-informed review of scientific and technological developments and future trends in hot stamping. International Journal of Lightweight Materials and Manufacture, 7 (2), 327–343. https://doi.org/10.1016/j.ijlmm.2023.11.003

- Athale, M., Park, T., Hahnlen, R., Pourboghrat, F. (2023). Design, performance, and cost savings of using GF-PC additively manufactured tooling for stamping of HSS 590 sheet metal. Journal of Manufacturing Processes, 101, 1–14. https://doi.org/10.1016/j.jmapro.2023.05.072

- Chen, S., Jiang, S., Wang, X., Sun, P., Hua, C., Sun, J. (2024). An efficient detector for detecting surface defects on cold-rolled steel strips. Engineering Applications of Artificial Intelligence, 138, 109325. https://doi.org/10.1016/j.engappai.2024.109325

- Liang, Y., Feng, S., Zhang, Y., Xue, F., Shen, F., Guo, J. (2024). A stable diffusion enhanced YOLOV5 model for metal stamped part defect detection based on improved network structure. Journal of Manufacturing Processes, 111, 21–31. https://doi.org/10.1016/j.jmapro.2023.12.064

- Suyitno, B. M., Rahman, R. A., Sukma, H., Rahmalina, D. (2022). The assessment of reflector material durability for concentrated solar power based on environment exposure and accelerated aging test. Eastern-European Journal of Enterprise Technologies, 6 (12 (120)), 22–29. https://doi.org/10.15587/1729-4061.2022.265678

- Psarommatis, F., Azamfirei, V. (2024). Zero Defect Manufacturing: A complete guide for advanced and sustainable quality management. Journal of Manufacturing Systems, 77, 764–779. https://doi.org/10.1016/j.jmsy.2024.10.022

- Ha, T., Welo, T., Ringen, G., Wang, J. (2024). Formability prediction of perforated sheet metal by representative volume element and homogenized sheet models. Manufacturing Letters, 42, 11–15. https://doi.org/10.1016/j.mfglet.2024.09.069

- Meng, Y., Yu, Q., Wu, X., Guo, X., Yang, Z., Xu, L., Chen, H. (2025). Oscillating laser-arc hybrid additive manufacturing of aluminum alloy thin-wall based on synchronous wire-powder feeding. Thin-Walled Structures, 206, 112665. https://doi.org/10.1016/j.tws.2024.112665

- Wan, F., Tian, H., Guan, F., Qi, C., Liao, J. (2024). On the spring-back and re-rounding mechanism of a plain dent on the sandwich pipe. Ocean Engineering, 313, 119491. https://doi.org/10.1016/j.oceaneng.2024.119491

- Chen, H., Li, S., Wang, J., Ding, A. (2021). A focused review on the thermo-stamping process and simulation progresses of continuous fibre reinforced thermoplastic composites. Composites Part B: Engineering, 224, 109196. https://doi.org/10.1016/j.compositesb.2021.109196

- Yang, J., Liu, B., Huang, H. (2024). Research on composition-process-property prediction of die casting Al alloys via combining feature creation and attention mechanisms. Journal of Materials Research and Technology, 28, 335–346. https://doi.org/10.1016/j.jmrt.2023.11.257

- Miao, Q., Dai, Z., Ma, G., Niu, F., Wu, D. (2023). Analysis of spring-back deformation of CF/PEEK thin angled laminates by laser-assisted forming. Composite Structures, 321, 117288. https://doi.org/10.1016/j.compstruct.2023.117288

- Pereira, G. C., Yoshida, M. I., LeBoulluec, P., Lu, W.-T., Alves, A. P., Avila, A. F. (2020). Application of artificial intelligence models for predicting time-dependent spring-back effect: The L-shape case study. Composites Science and Technology, 199, 108251. https://doi.org/10.1016/j.compscitech.2020.108251

- Sajan, M., Amirthalingam, M., Chakkingal, U. (2021). A novel method for the spring-back analysis of a hot stamping steel. Journal of Materials Research and Technology, 11, 227–234. https://doi.org/10.1016/j.jmrt.2021.01.017

- Chanda, A., Bhattacharyya, D. (2021). A parametric study to minimise spring-back while producing plywood channels. Journal of Cleaner Production, 304, 127109. https://doi.org/10.1016/j.jclepro.2021.127109

- Shojaei, M., Khayati, G. R., por, H. H., Khorasani, S. M. J., Hernashki, R. K. (2021). Investigation of spring back phenomenon in the 316L stainless steel cathode blank based on the changes in electrical resistivity and magnetic properties due to the residual stress and martensite phase formation: An industrial failure. Engineering Failure Analysis, 126, 105473. https://doi.org/10.1016/j.engfailanal.2021.105473

- Husmann, H., Hauska, B., Liu, C., Groche, P. (2022). Exploiting spring-back differences for joining and pre-stressing sheet metal structures with tendons during forming – A mathematical-physical process model. Journal of Materials Processing Technology, 307, 117683. https://doi.org/10.1016/j.jmatprotec.2022.117683

- Chinara, M., Paul, S. K., Chatterjee, S., Mukherjee, S. (2023). Effect of central hole edge preparation, coefficient of friction and spring-back on hole expansion ratio of automotive steels. Journal of Alloys and Metallurgical Systems, 4, 100046. https://doi.org/10.1016/j.jalmes.2023.100046

- Li, H., Xie, S.-R., Zhang, S.-H., Chen, S.-F., Song, H.-W., Xu, Y., Pokrovsky, A. I., Khina, B. B. (2023). Spring-back behaviors of Ti-6Al-4V sheet under effect of strain rate. International Journal of Mechanical Sciences, 260, 108646. https://doi.org/10.1016/j.ijmecsci.2023.108646

- ISO 7438:2020. Metallic materials – Bend test. https://www.iso.org/standard/72187.html

- Martínez-Martínez, A., Miguel, V., Coello, J. (2024). A numerical model to analyse the under-tension-bending-unbending processes. Special analysis for determining the spring-back of TRIP 690 steel sheet. Journal of Manufacturing Processes, 129, 92–108. https://doi.org/10.1016/j.jmapro.2024.08.039

- ASTM E3-11. Standard Guide for Preparation of Metallographic Specimens. Available at: https://cdn.standards.iteh.ai/samples/97288/dc8875fd159648d6a39eb8f1df1d4b7f/ASTM-E3-11-2017-.pdf

- Etemadi, E., Naseri, A., Valinezhad, M. (2020). Novel U-bending designed setups for investigating the spring-back/spring-go of two-layer aluminum/copper sheets through experimental tests and finite element simulations. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 234 (8), 1142–1153. https://doi.org/10.1177/1464420720930251

- Özdemir, M., Dilipak, H., Bostan, B. (2020). Experimental Investigation of Deformation and Spring-Back and Spring-Go Amounts of 1.5415 (16MO3) Sheet Material. Metallography, Microstructure, and Analysis, 9 (6), 796–806. https://doi.org/10.1007/s13632-020-00687-6

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dwi Rahmalina, Ahmad Zamzami

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.