Development of a method for combined control of thickness, tension and flatness of strips in continuous cold rolling to reduce longitudinal thickness variation and nonflatness

DOI:

https://doi.org/10.15587/1729-4061.2025.325416Keywords:

continuous cold rolling, flatness and strip thickness control system, combined controlAbstract

The object of study is the process of continuous cold rolling of strips, in which the parameters of thickness, tension and flatness of the metal.

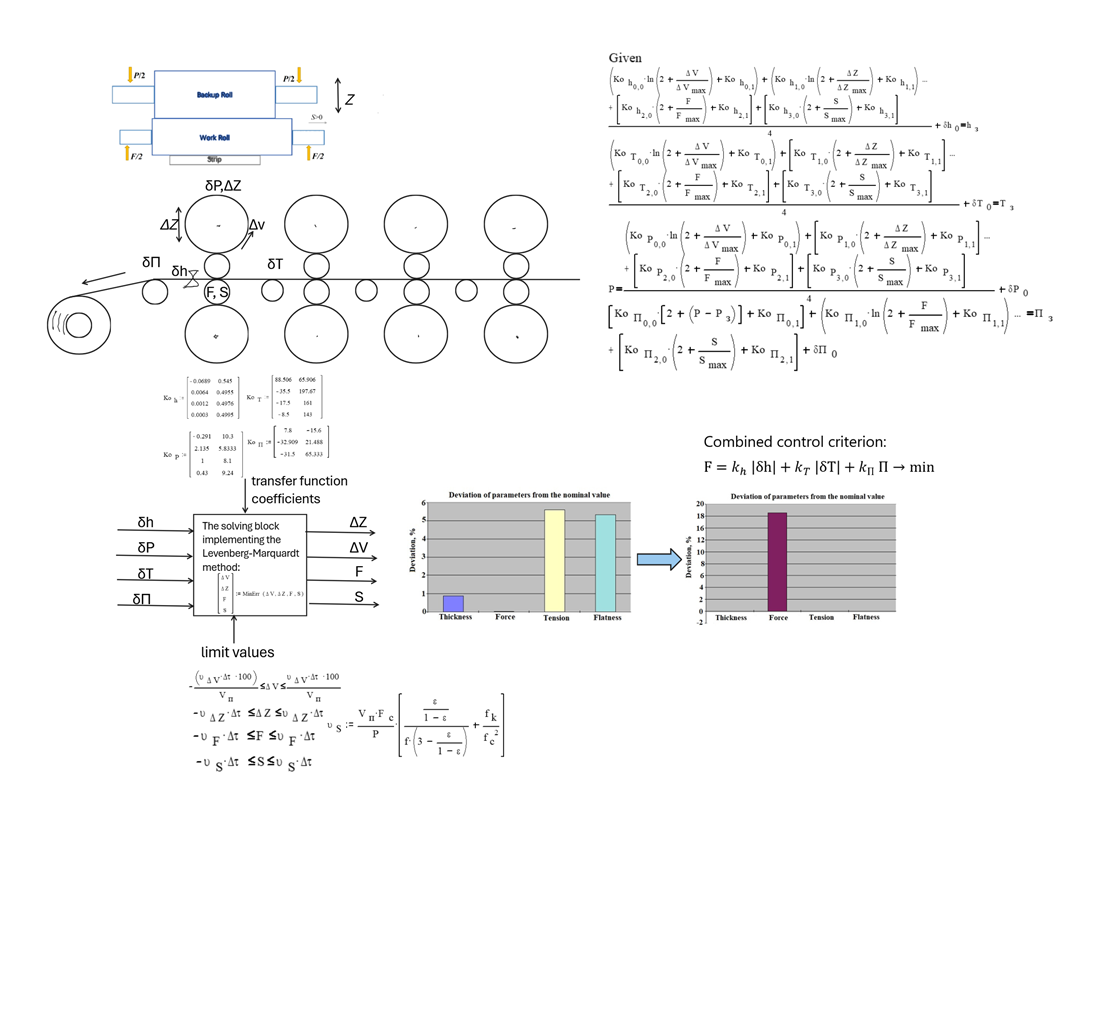

Obtaining high flatness of thin strips during cold rolling at industrial 4-stand mills, where the last stand realizes significant degrees of compression in the working rolls with a diameter of up to 500 mm, when implementing the mode with a constant rolling force causes an increase in the longitudinal thickness deviation of strips. And the accentuated obtaining of minimum longitudinal thickness variation of strips leads to a change in the rolling force and as a result, due to the change in the deflection of rolls worsens the flatness of strips. The results of control actions can worsen both main quality indicators at the same time. The known methods of thickness and flatness control during cold rolling are analyzed and an alternative method of combined influence on these quality indicators is proposed. An optimization criterion is proposed. The quantitative estimation of the achieved simultaneous improvement of accuracy in thickness and flatness of strips as a result of the combined impact due to the realization of the optimal combination of interrelated control actions is performed. The method and algorithm of combined influence on thickness, tension and flatness of strips taking into account speed capabilities of actuators and their current position are proposed to reduce longitudinal fluctuations of thickness and nonflatness.

Simultaneous decrease of strip nonflatness and longitudinal thickness fluctuations is explained by the optimal combination of regulation channels. This method can be used on modern mills based on local systems of automatic control of strip thickness and flatness.

Numerical estimations of probable practical results achieved when using the proposed method. A simultaneous reduction in strip flatness of 20–30 % and the provision of limited thickness limit deviations to EN 10131(S) in at least 80 % of the inter-grade transitions are expected

References

- Roberts, W. L. (1988). Flat processing of steel. New York: M. Dekker, 905.

- Jortner, D., Osterle, J. F., Zorowski, C. F. (1960). An analysis of cold strip rolling. International Journal of Mechanical Sciences, 2 (3), 179–194. https://doi.org/10.1016/0020-7403(60)90003-5

- Bemporad, A., Bernardini, D., Cuzzola, F. A., Spinelli, A. (2010). Optimization-based automatic flatness control in cold tandem rolling. Journal of Process Control, 20 (4), 396–407. https://doi.org/10.1016/j.jprocont.2010.02.003

- Zhao, J., Li, J., Yang, Q., Wang, X., Ding, X., Peng, G. et al. (2023). A novel paradigm of flatness prediction and optimization for strip tandem cold rolling by cloud-edge collaboration. Journal of Materials Processing Technology, 316, 117947. https://doi.org/10.1016/j.jmatprotec.2023.117947

- Babajamali, Z., khabaz, M. K., Aghadavoudi, F., Farhatnia, F., Eftekhari, S. A., Toghraie, D. (2022). Pareto multi-objective optimization of tandem cold rolling settings for reductions and inter stand tensions using NSGA-II. ISA Transactions, 130, 399–408. https://doi.org/10.1016/j.isatra.2022.04.002

- Ding, C.-Y., Ye, J.-C., Lei, J.-W., Wang, F.-F., Li, Z.-Y., Peng, W. et al. (2024). An interpretable framework for high-precision flatness prediction in strip cold rolling. Journal of Materials Processing Technology, 329, 118452. https://doi.org/10.1016/j.jmatprotec.2024.118452

- Wang, Q., Sun, J., Li, X., Wang, Z., Wang, P., Zhang, D. (2020). Analysis of lateral metal flow-induced flatness deviations of rolled steel strip: Mathematical modeling and simulation experiments. Applied Mathematical Modelling, 77, 289–308. https://doi.org/10.1016/j.apm.2019.07.036

- Golubchenko, A. K., Mazur, V. L., Prykhodko, I. Yu. (1994). Analysis of the influence of the automatic control system of strip thickness and tension in the process of continuous cold rolling of strips based on simulation modeling. Metallurgical and Mining Industry, 4, 19–24.

- Mazur, V. L., Nogovitsyn, O. V. (2018). Theory and Technology of Sheet Rolling. CRC Press. https://doi.org/10.1201/9781351173964

- Prykhodko, I. Yu. et al. (1990). Mathematical model for calculating the transverse profile and shape of strips during cold rolling in a quarto stand with axial shift and forced bending of working rolls with an asymmetric profile. Iron and Steel Institute, Dnepropetrovsk. Chermetinformatsiya. No. 5620.

- Safyan, A. M., Prykhodko, I. Yu. (1996). Computer system of parameters calculation and optimization of cold strip rolling. Part 2. Metallurgical and Mining Industry, 1, 29–33.

- Prykhodko, I. Y., Raznosilin, V. V. (2005). Computer system WinColdRolling. Certificate of Copyright Registration No. 15149. Issued by the State Department of Intellectual Property of the Ministry of Education and Science of Ukraine, Date of Registration 29.12.2005. Available at: https://iprop-ua.com/cr/gmk1pxjx/

- Prikhod’ko, I. Yu., Chernov, P. P., Raznosilin, V. V., Sergeenko, A. A., Trusillo, S. V., Agureev, V. A. et al. (2009). Automatic control of strip planarity and temperature by contactless methods. Steel in Translation, 39 (3), 251–256. https://doi.org/10.3103/s0967091209030176

- Carlton, A. J., Conway, G. H., Davies, G. G., Edwards, W. J., Spooner, P. D. (1992). Automation of the LTV Steel Hennepin Tandem Cold Mill. Iron and Steel Engineer.

- Davies, R., Edwards, W. J., Medioli, A. M., Thomas, P. J., Floyd, S. (1996). Itnegrated Automation Systems For Reversing Mill. 5-th International Conference Steel Strip. Ostrava.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Wu Hongyi, Ihor Prykhodko, Zuo Peng, Wang Debin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.