Розробка підходів до біоконверсії харчових волокон у макусі льону за допомогою целюлолітичних ферментів

DOI:

https://doi.org/10.15587/1729-4061.2025.325418Ключові слова:

целюлолітичні ферменти, харчові волокна, макуха льону, α-ліноленова кислота, антиоксидантиАнотація

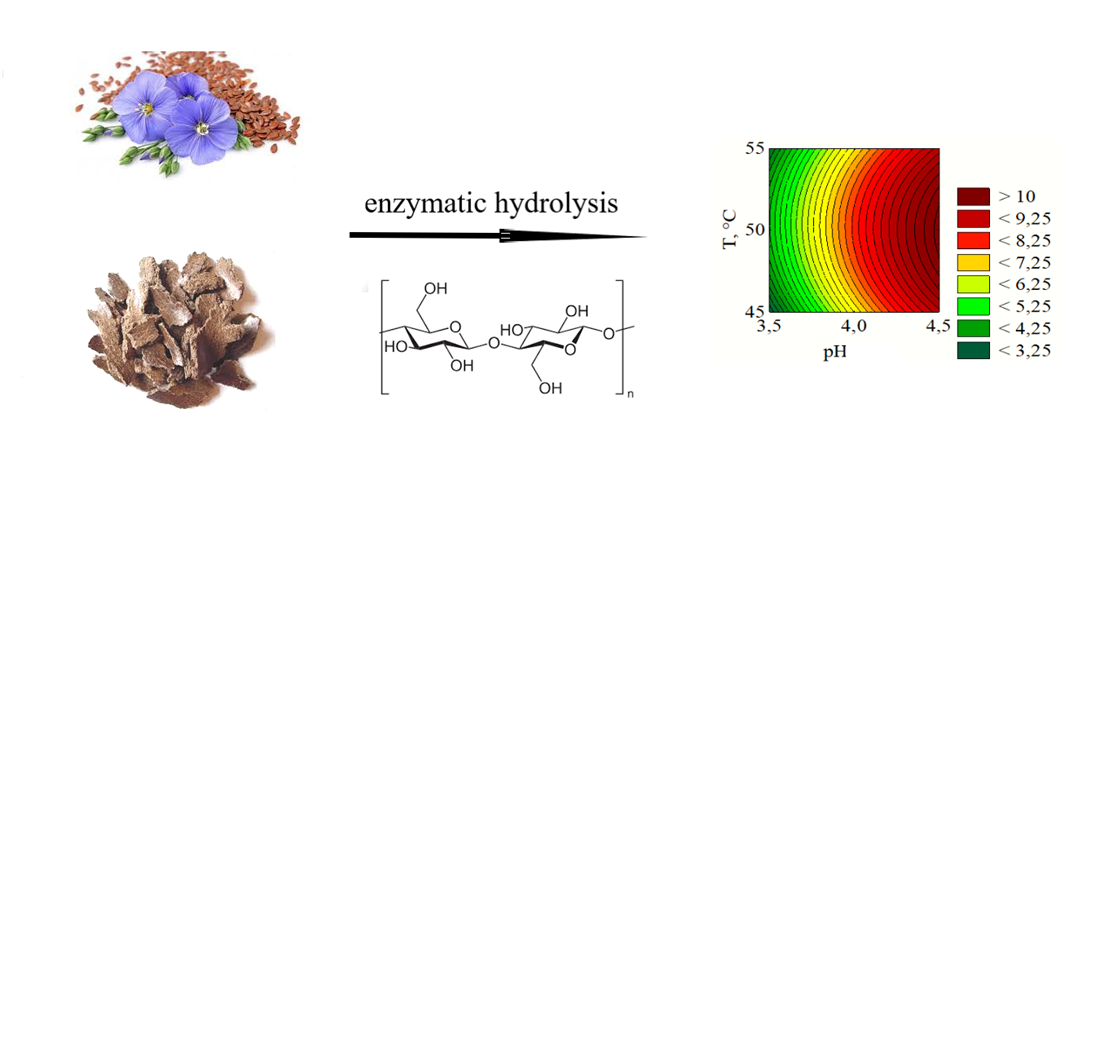

Об’єктом дослідження є процес ферментативного гідролізу харчових волокон у макусі льону, спрямований на біоконверсію целюлози в розчинні цукри. В роботі розглянуто використання целюлолітичних ферментів та антиоксиданту для гідролізу целюлози у макусі льону. Це дозволяє підвищити біодоступність розчинних цукрів та інших поживних сполук, а також зберегти від окисної деструкції поліненасичені жирні кислоти (ПНЖК) ліпідної складової макухи, зокрема альфа-ліноленову кислоту (ALA). Визначено раціональні параметри процесу ферментативного гідролізу: pH 4,5 і температура 50 °C, що забезпечують максимальний вихід розчинних цукрів (11,4 %) при мінімальних втратам ALA (9,0 %). Також розглянуто застосування антиоксиданту – натрієвої солі ериторбової кислоти (E 316) для захисту ПНЖК від окисного псування під час ферментативного гідролізу. Найбільш ефективною виявилася концентрація ериторбату натрію 0,03–0,035 %, що мінімізує втрати ALA до 1,4 %. Результати досліджень мають важливе значення для розробки нових технологій переробки макухи льону, що сприятимуть покращенню якості продуктів та їх збереженню протягом тривалого періоду. Отримані результати пояснюються біохімічними та хімічними взаємодіями між компонентами реакційної суміші (ферментом, буфером, антиоксидантом) та складовими макухи льону (харчовими волокнами, ліпідним комплексам). Це призводить до підвищення ефективності гідролізу целюлози та збереження ПНЖК від окиснення. Отримані результати дозволяють розглядати макуху льону з гідролізованою целюлозою як перспективний продукт для харчової промисловості та виробництва кормів

Посилання

- Makarova, A., Baurin, D., Gordienko, M., Kudryavtseva, E., Grosheva, V., Yakubovich, L. (2017). Algorithm of multi-criterion green process assessment for renewable raw materials bioconversion. Journal of Cleaner Production, 162, 380–390. https://doi.org/10.1016/j.jclepro.2017.06.013

- Stankevych, S., Gorbunov, K., Zabrodina, I., Popov, M., Kalyna, V., Novozhylova, T. et al. (2024). Identification of the oxidation and hydrolysis products content influence on the rapeseed oil oxidation induction period. Technology Organic and Inorganic Substances, 4 (6 (130)), 6–13. https://doi.org/10.15587/1729-4061.2024.308907

- Belinska, A., Bliznjuk, O., Masalitina, N., Bielykh, I., Zviahintseva, O., Gontar, T. et al. (2023). Development of biotechnologically transesterified three-component fat systems stable to oxidation. Eastern-European Journal of Enterprise Technologies, 5 (6 (125)), 21–28. https://doi.org/10.15587/1729-4061.2023.287326

- Kaur, M., Singh, A. K., Singh, A. (2023). Bioconversion of food industry waste to value added products: Current technological trends and prospects. Food Bioscience, 55, 102935. https://doi.org/10.1016/j.fbio.2023.102935

- Mishra, A. P., Devkota, H. P., Nigam, M., Adetunji, C. O., Srivastava, N., Saklani, S. et al. (2020). Combination of essential oils in dairy products: A review of their functions and potential benefits. LWT, 133, 110116. https://doi.org/10.1016/j.lwt.2020.110116

- Petik, I., Litvinenko, O., Stankevych, S., Zabrodina, I., Ponomarova, M., Kotliar, O. et al. (2024). Determination of the cellulose- and lipid-containing components influence on the extrudate technological indicators. Eastern-European Journal of Enterprise Technologies, 2 (6 (128)), 6–13. https://doi.org/10.15587/1729-4061.2024.301843

- Abilmazhinov, Y., Bekeshova, G., Nesterenko, A., Dibrova, Z., Ermolaev, V., Ponomarev, E., Vlasova, V. (2023). A Review on The Improvement of Extruded Food Processing Equipment: Extrusion Cooking in Food Processing. Food Science and Technology, 43. https://doi.org/10.5327/fst.80621

- Al-molah, M. I., Kloor, I. S. (2023). The Effect of Substituting De-Hulled Sunflower Meal Instead of Soybean Meal with or Without Adding Xylanase Enzyme to the Ration on Productive Performance and Carcass Characteristics of Broiler Chicks. IOP Conference Series: Earth and Environmental Science, 1259 (1), 012074. https://doi.org/10.1088/1755-1315/1259/1/012074

- Lannuzel, C., Smith, A., Mary, A. L., Della Pia, E. A., Kabel, M. A., de Vries, S. (2022). Improving fiber utilization from rapeseed and sunflower seed meals to substitute soybean meal in pig and chicken diets: A review. Animal Feed Science and Technology, 285, 115213. https://doi.org/10.1016/j.anifeedsci.2022.115213

- Petik, I., Litvinenko, O., Kalyna, V., Ilinska, O., Raiko, V., Filenko, O. et al. (2023). Development of extruded animal feed based on fat and oil industry waste. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 112–120. https://doi.org/10.15587/1729-4061.2023.275509

- Bochkarev, S., Chaika, T., Stankevych, S., Zabrodina, I., Balandina, I., Obolentseva, L. et al. (2024). Development of an extruded system with enhanced content of alpha-linolenic polyunsaturated fatty acid. Eastern-European Journal of Enterprise Technologies, 6 (11 (132)), 15–23. https://doi.org/10.15587/1729-4061.2024.315246

- Belinska, A., Ryshchenko, I., Bliznjuk, O., Masalitina, N., Siedykh, K., Zolotarova, S. et al. (2024). Development of a method for inactivating lipoxygenases in linseed using chemical reagents. Technology Organic and Inorganic Substances, 4 (6 (130)), 14–21. https://doi.org/10.15587/1729-4061.2024.309079

- Hyde, K. D., Xu, J., Rapior, S., Jeewon, R., Lumyong, S., Niego, A. G. T. et al. (2019). The amazing potential of fungi: 50 ways we can exploit fungi industrially. Fungal Diversity, 97 (1), 1–136. https://doi.org/10.1007/s13225-019-00430-9

- Talwar, B., Chopra, R., Taneja, N. K., Chand, M., Homroy, S., Dhiman, A. et al. (2025). Use of flaxseed cake as a source of nutrients in the food industry and possible health benefits- a review. Food Production, Processing and Nutrition, 7 (1). https://doi.org/10.1186/s43014-024-00294-w

- Song, Y., Sun, L., Wang, H., Zhang, S., Fan, K., Mao, Y. et al. (2023). Enzymatic fermentation of rapeseed cake significantly improved the soil environment of tea rhizosphere. BMC Microbiology, 23 (1). https://doi.org/10.1186/s12866-023-02995-7

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Anna Belinska, Igor Ryshchenko, Olga Bliznjuk, Nataliia Masalitina, Maryna Chuiko, Yana Svishchova, Tatiana Gavrish, Maryna Ponomarova, Mykola Denysenko, Olexii Varypaiev

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.