Визначення впливу гідратованого вапна на самовідновлювальний щебенево-мастичний асфальт зі сталевого шлаку за допомогою методу індукційного нагрівання в тропічних умовах

DOI:

https://doi.org/10.15587/1729-4061.2025.325722Ключові слова:

сталевий шлак, щебенево-мастиковий асфальт, індукційне нагрівання, самовідновлення, випробування на триточковий згин, тропічні умовиАнотація

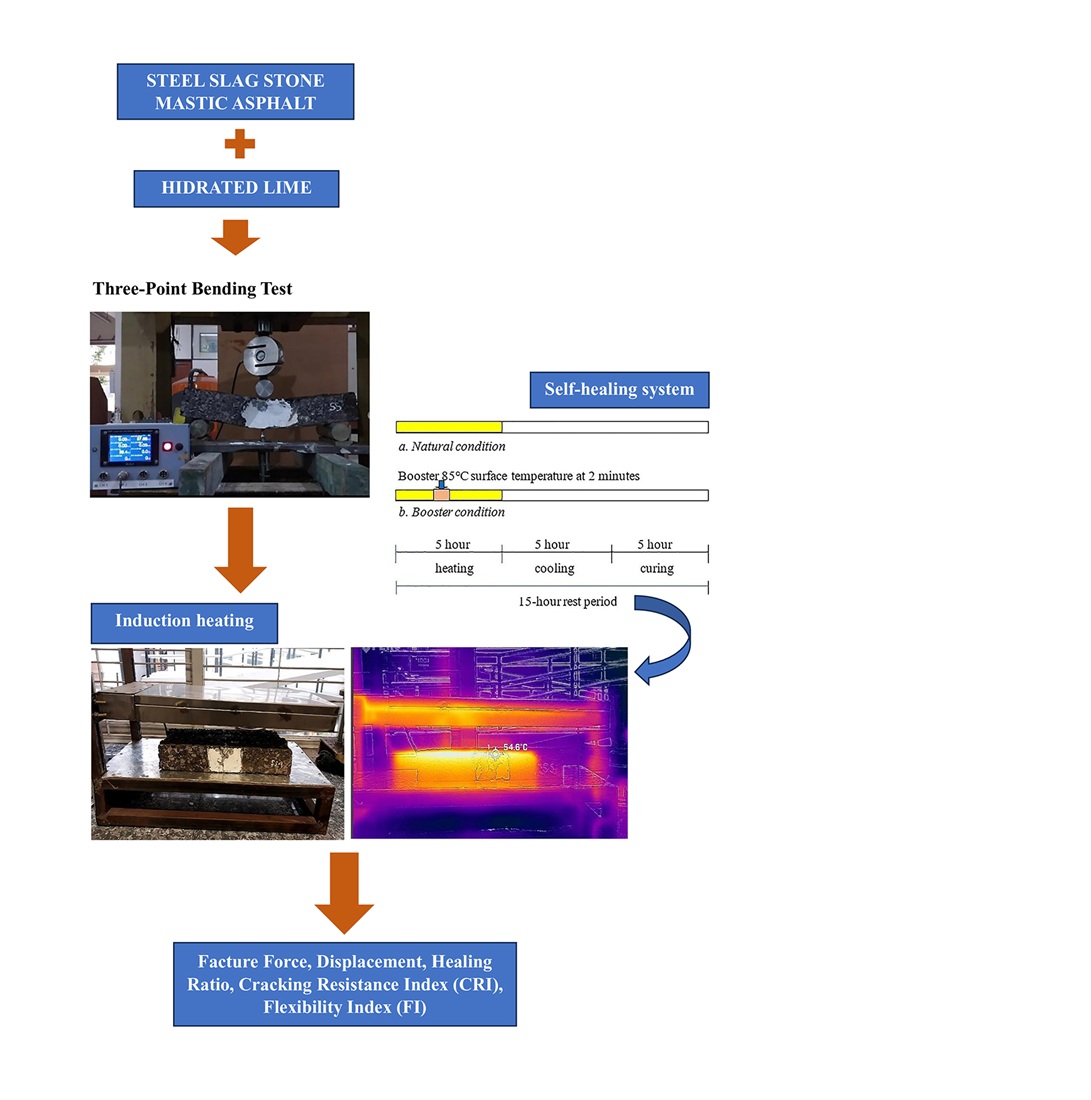

У цьому дослідженні розглядається вплив добавки гашеного вапна на щебенево-мастиковий асфальт зі сталевого шлаку для індукційного нагрівання та індукованого відновлення. У ньому оцінюються самовідновлювальні властивості щебенево-мастикового асфальту зі сталевого шлаку, модифікованого гашеним вапном, у тропічних умовах.

Триточковий згин спочатку був випробуваний на суміші щебенево-мастикового асфальту зі сталевого шлаку, модифікованій гашеним вапном (1 %, 2 %, 3 % та 4 % від ваги суміші). Оцінено руйнування, зміщення, стійкість до розтріскування та індекс гнучкості суміші. Згодом було досліджено руйнування, зміщення, стійкість до розтріскування, відновлення індексу гнучкості та коефіцієнт відновлення для пошкоджень та відновлення. У дослідженні використовується індукційний нагрів, який регулює температуру відповідно до природних тропічних умов. Процес відновлення порівнюється між нагріванням у тропічному середовищі та нагріванням з додатковою температурою.

Результати показали, що додавання гашеного вапна до щебенево-мастикового асфальту зі сталевого шлаку збільшило міцність на розрив, проте це покращення супроводжувалося зменшенням зміщення, стійкості до розтріскування та гнучкості. Результати дослідження показують, що коефіцієнт відновлення щебенево-мастикового асфальту зі сталевого шлаку покращується на 1 % гашеного вапна. Додавання 1 % гашеного вапна є оптимальним для покращення міцності на розрив та коефіцієнта відновлення. Міцність на розрив збільшилася на 5 % при варіації 1 % гашеного вапна. Коефіцієнт відновлення модифікованого 1 % гашеного вапна мастикового асфальту збільшився на 14,57 % за природних умов порівняно з 0 % гашеного вапна щебенево-мастикового асфальту зі сталевого шлаку. Крім того, коефіцієнт відновлення щебенево-мастикового асфальту зі сталевого шлаку з 1 % гашеного вапна, що піддавався штучному нагріванню, збільшився на 22,08 % порівняно з мастиковим асфальтом з 0 % гашеного вапна за природних умов

Посилання

- Diao, H., Ling, T., Zhang, Z., Peng, B., Huang, Q. (2023). Multiscale Fatigue Performance Evaluation of Hydrated Lime and Basalt Fiber Modified Asphalt Mixture. Materials, 16 (10), 3608. https://doi.org/10.3390/ma16103608

- Movilla-Quesada, D., Raposeiras, A. C., Castro-Fresno, D., Peña-Mansilla, D. (2015). Experimental study on stiffness development of asphalt mixture containing cement and Ca(OH)2 as contribution filler. Materials & Design, 74, 157–163. https://doi.org/10.1016/j.matdes.2015.02.026

- Carvajal-Muñoz, J. S., Airey, G., Sanjuan-Benavides, A., Perez-Miranda, M. A., Gómez-Osorio, F. A. (2024). Fracture characteristics of SMA mixtures with hydrated lime through the semi-circular bending approach. Construction and Building Materials, 449, 138353. https://doi.org/10.1016/j.conbuildmat.2024.138353

- Liu, J., Wang, Z., Li, M., Wang, X., Wang, Z., Zhang, T. (2022). Microwave heating uniformity, road performance and internal void characteristics of steel slag asphalt mixtures. Construction and Building Materials, 353, 129155. https://doi.org/10.1016/j.conbuildmat.2022.129155

- Phan, T. M., Park, D.-W., Le, T. H. M. (2018). Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Construction and Building Materials, 180, 503–511. https://doi.org/10.1016/j.conbuildmat.2018.05.278

- Irawati, I., Djakfar, L., Arifin, M. Z. (2023). Comparison of the moisture resistance of a steel-slag stone mastic asphalt mixture modified with Ca(OH)2. Eastern-European Journal of Enterprise Technologies, 6 (6 (126)), 62–70. https://doi.org/10.15587/1729-4061.2023.289054

- Carvajal-Muñoz, J. S., Airey, G., Hernández-De Las Salas, R. D., Contreras-Barbas, M. A., Rodríguez-Verdecia, S. A. (2024). Fundamental cracking performance of asphalt-filler mastics with hydrated lime. Construction and Building Materials, 453, 139029. https://doi.org/10.1016/j.conbuildmat.2024.139029

- Xiang, H., He, Z., Chen, L., Zhu, H., Wang, Z. (2019). Key Factors and Optimal Conditions for Self-Healing of Bituminous Binder. Journal of Materials in Civil Engineering, 31 (9). https://doi.org/10.1061/(asce)mt.1943-5533.0002760

- Lou, B., Sha, A., Li, Y., Wang, W., Liu, Z., Jiang, W., Cui, X. (2020). Effect of metallic-waste aggregates on microwave self-healing performances of asphalt mixtures. Construction and Building Materials, 246, 118510. https://doi.org/10.1016/j.conbuildmat.2020.118510

- Liu, Q., Schlangen, E., van de Ven, M. F. C., van Bochove, G., van Montfort, J. (2012). Predicting the Performance of the Induction Healing Porous Asphalt Test Section. 7th RILEM International Conference on Cracking in Pavements, 1081–1089. https://doi.org/10.1007/978-94-007-4566-7_103

- Liu, Q., Schlangen, E., van de Ven, M., van Bochove, G., van Montfort, J. (2012). Evaluation of the induction healing effect of porous asphalt concrete through four point bending fatigue test. Construction and Building Materials, 29, 403–409. https://doi.org/10.1016/j.conbuildmat.2011.10.058

- Vila-Cortavitarte, M., Jato-Espino, D., Castro-Fresno, D., Calzada-Pérez, M. Á. (2018). Self-Healing Capacity of Asphalt Mixtures Including By-Products Both as Aggregates and Heating Inductors. Materials, 11 (5), 800. https://doi.org/10.3390/ma11050800

- Li, H., Yu, J., Wu, S., Liu, Q., Li, Y., Wu, Y., Xu, H. (2019). Investigation of the Effect of Induction Heating on Asphalt Binder Aging in Steel Fibers Modified Asphalt Concrete. Materials, 12 (7), 1067. https://doi.org/10.3390/ma12071067

- Kaseer, F., Yin, F., Arámbula-Mercado, E., Epps Martin, A., Daniel, J. S., Salari, S. (2018). Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Construction and Building Materials, 167, 286–298. https://doi.org/10.1016/j.conbuildmat.2018.02.014

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Irawati Irawati, Ludfi Djakfar, Muhammad Zainul Arifin, Akhmad Sabarudin, Ilanka Cahya Dewi, Irawan Palgunadi

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.