Визначення раціональних умов етерифікування жирних кислот соняшникового соапстоку

DOI:

https://doi.org/10.15587/1729-4061.2025.326031Ключові слова:

бутилові ефіри жирних кислот, етерифікування жирних кислот, відходи олієжирової галузіАнотація

Об’єктом дослідження є процес етерифікування жирних кислот соняшникового соапстоку бутанолом.

Соапсток є відходом олієжирової галузі, який утворюється в процесі лужної нейтралізації олій. Перспективною є переробка соапстоку з отриманням жирних кислот, оскільки утилізація відходу є складною та небезпечною, а жирні кислоти є промислово цінним продуктом. Жирні кислоти, отримані із соапстоку, є доступною сировиною для виробництва жирнокислотних ефірів низькомолекулярних спиртів, які є основою альтернативного біодизельного палива.

Досліджено вплив умов етерифікування жирних кислот із соняшникового соапстоку (CAS Number 61788-66-7) бутанолом (CAS Number 71-36-3) у присутності каталізатору алкілбензолсульфокислоти на кислотне число реакційної суміші. Даний показник відображає підвищення вмісту бутилових ефірів.

Використані жирні кислоти, отримані із соапстоку шляхом розкладання сірчаною кислотою, відповідають вимогам ДСТУ 4860 для жирних кислот першого ґатунку. Число нейтралізації жирних кислот становить 186,0 мг КОН/г, масова частка вологи та летких речовин – 1,7 %, масова частка загального жиру – 97,5 %, глибина розщеплення – 67,1 % олеїнової кислоти.

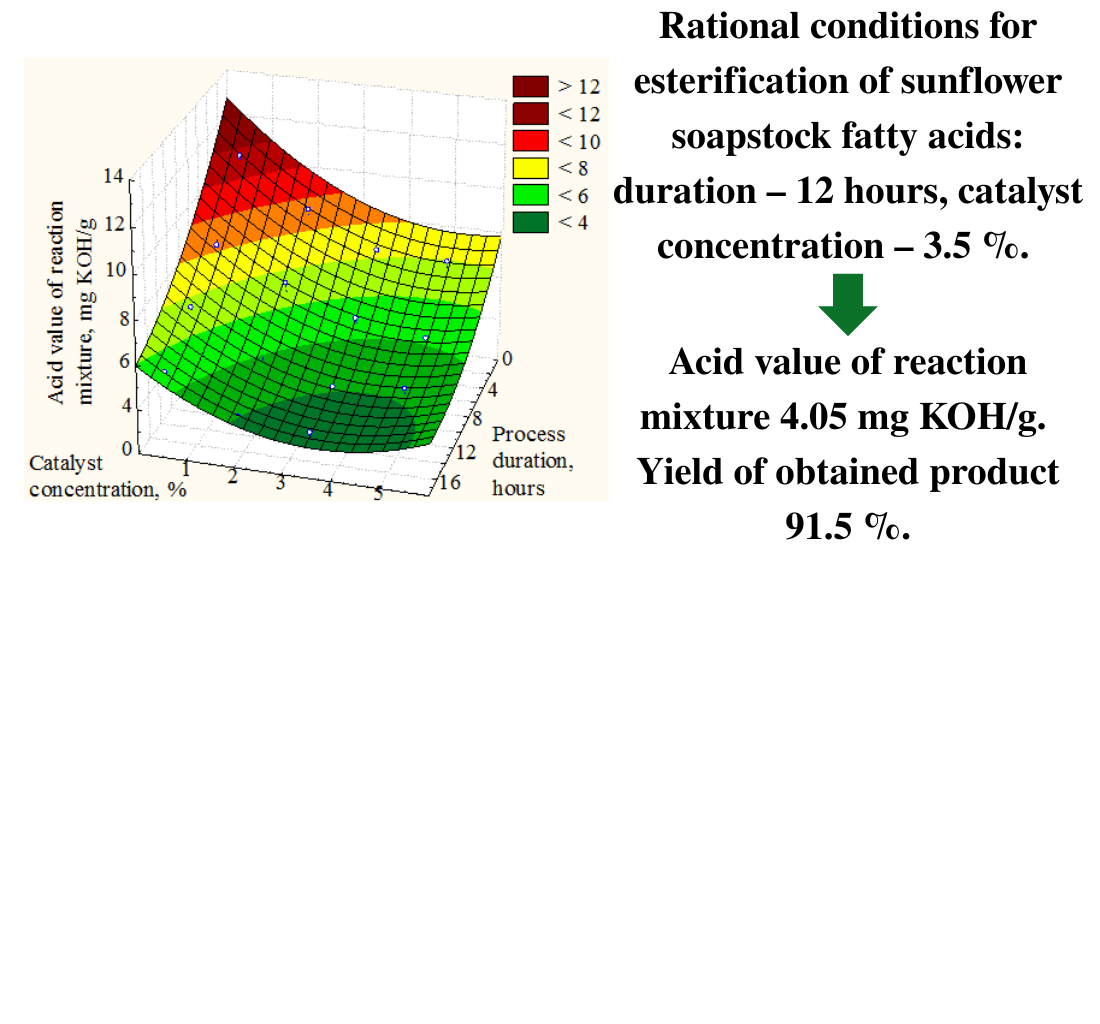

Встановлено раціональні умови процесу етерифікування, які відповідають максимальному зниженню кислотного числа реакційної суміші: тривалість – 12 год., концентрація каталізатору – 3,5 %. При цьому кислотне число реакційної маси склало 4,05 мг КОН/г. Вихід продукту склав 91,5 %. Показники продукту: масова частка ефірів – 92,7 %, масова частка загального гліцерину – 0,20 %, масова частка вологи 0,04 %, густина за температури 15 °C – 840 кг/м3.

Одержані результати дають можливість отримувати якісну основу для біодизельного палива з використанням жирних кислот соапстоку за раціональних умов

Посилання

- Babadi, A. A., Rahmati, S., Fakhlaei, R., Barati, B., Wang, S., Doherty, W., Ostrikov, K. (Ken). (2022). Emerging technologies for biodiesel production: Processes, challenges, and opportunities. Biomass and Bioenergy, 163, 106521. https://doi.org/10.1016/j.biombioe.2022.106521

- Mahlia, T. M. I., Syazmi, Z. A. H. S., Mofijur, M., Abas, A. E. P., Bilad, M. R., Ong, H. C., Silitonga, A. S. (2020). Patent landscape review on biodiesel production: Technology updates. Renewable and Sustainable Energy Reviews, 118, 109526. https://doi.org/10.1016/j.rser.2019.109526

- Sytnik, N., Kunitsia, E., Mazaeva, V., Kalyna, V., Chernukha, A., Vazhynskyi, S. et al. (2021). Rational conditions of fatty acids obtaining by soapstock treatment with sulfuric acid. Eastern-European Journal of Enterprise Technologies, 4 (6 (112)), 6–13. https://doi.org/10.15587/1729-4061.2021.236984

- Kurczyński, D., Wcisło, G., Leśniak, A., Kozak, M., Łagowski, P. (2022). Production and Testing of Butyl and Methyl Esters as New Generation Biodiesels from Fatty Wastes of the Leather Industry. Energies, 15 (22), 8744. https://doi.org/10.3390/en15228744

- Ali Ijaz Malik, M., Zeeshan, S., Khubaib, M., Ikram, A., Hussain, F., Yassin, H., Qazi, A. (2024). A review of major trends, opportunities, and technical challenges in biodiesel production from waste sources. Energy Conversion and Management: X, 23, 100675. https://doi.org/10.1016/j.ecmx.2024.100675

- Konovalov, S., Patrylak, L., Zubenko, S., Okhrimenko, M., Yakovenko, A., Levterov, A., Avramenko, A. (2021). Bench Motor Testing of Blended Fuels on their Basis. Chemistry & Chemical Technology, 15 (1), 105–117. https://doi.org/10.23939/chcht15.01.105

- Konovalov, S. V., Zubenko, S. O., Patrylak, L. K., Yakovenko, A. V. (2021). Fuel-grade sunflower oil butyl esters: synthesis, purification, oxidation stability. Catalysis and Petrochemistry, 32, 40–53. https://doi.org/10.15407/kataliz2021.32.040

- Navas, M. B., Lick, I. D., Bolla, P. A., Casella, M. L., Ruggera, J. F. (2018). Transesterification of soybean and castor oil with methanol and butanol using heterogeneous basic catalysts to obtain biodiesel. Chemical Engineering Science, 187, 444–454. https://doi.org/10.1016/j.ces.2018.04.068

- Gaide, I., Makareviciene, V., Sendzikiene, E., Gumbytė, M. (2023). Rapeseed Oil Transesterification Using 1-Butanol and Eggshell as a Catalyst. Catalysts, 13 (2), 302. https://doi.org/10.3390/catal13020302

- Sathish Kumar, R., Krupa Vara Prasad, A. (2019). Environment friendly butyl ester biodiesel production from mahua oil: optimization and characterization. SN Applied Sciences, 1 (8). https://doi.org/10.1007/s42452-019-0913-6

- Ilmi, M., Abduh, M. Y., Hommes, A., Winkelman, J. G. M., Hidayat, C., Heeres, H. J. (2018). Process Intensification of Enzymatic Fatty Acid Butyl Ester Synthesis Using a Continuous Centrifugal Contactor Separator. Industrial & Engineering Chemistry Research, 57 (2), 470–482. https://doi.org/10.1021/acs.iecr.7b03297

- Sousa, R. R. de, Lázaro, C. da C., Gomes, C. B. de S. M. R., Silva, A. S. da, Fernandez-Lafuente, R., Ferreira-Leitão, V. S. (2023). Butyl-esters synthesis from palm fatty acid distillate catalyzed by immobilized lipases in solvent-free system – Optimization using a simplified method (SER). Process Biochemistry, 128, 158–166. https://doi.org/10.1016/j.procbio.2023.02.030

- Todeschini, J. K. P., Aguieiras, E. C. G., Castro, A. M. de, Langone, M. A. P., Freire, D. M. G., Rodrigues, R. C. (2016). Synthesis of butyl esters via ultrasound-assisted transesterification of macaúba (Acrocomia aculeata) acid oil using a biomass-derived fermented solid as biocatalyst. Journal of Molecular Catalysis B: Enzymatic, 133, S213–S219. https://doi.org/10.1016/j.molcatb.2017.01.007

- Wallis, C., Cerny, M., Lacroux, E., Mouloungui, Z. (2017). Recovery of slaughterhouse Animal Fatty Wastewater Sludge by conversion into Fatty Acid Butyl Esters by acid-catalyzed esterification. Waste Management, 60, 184–190. https://doi.org/10.1016/j.wasman.2016.07.003

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Gabriella Birta, Nadiya Levoshko, Vladyslav Knysh, Svitlana Usenko, Anatolii Shostia, Tetiana Ovsiannikova, Tetiana Falalieieva, Larysa Marushko, Yevhen Semenko, Sergii Zygin

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.