Multi-objective optimization of boiler combustion efficiency and emissions using genetic algorithm and recurrent neural network in 660-MW coal-fired power plant

DOI:

https://doi.org/10.15587/1729-4061.2025.327063Keywords:

boiler efficiency, co-firing, artificial neural network, genetic algorithm, net zero emissionAbstract

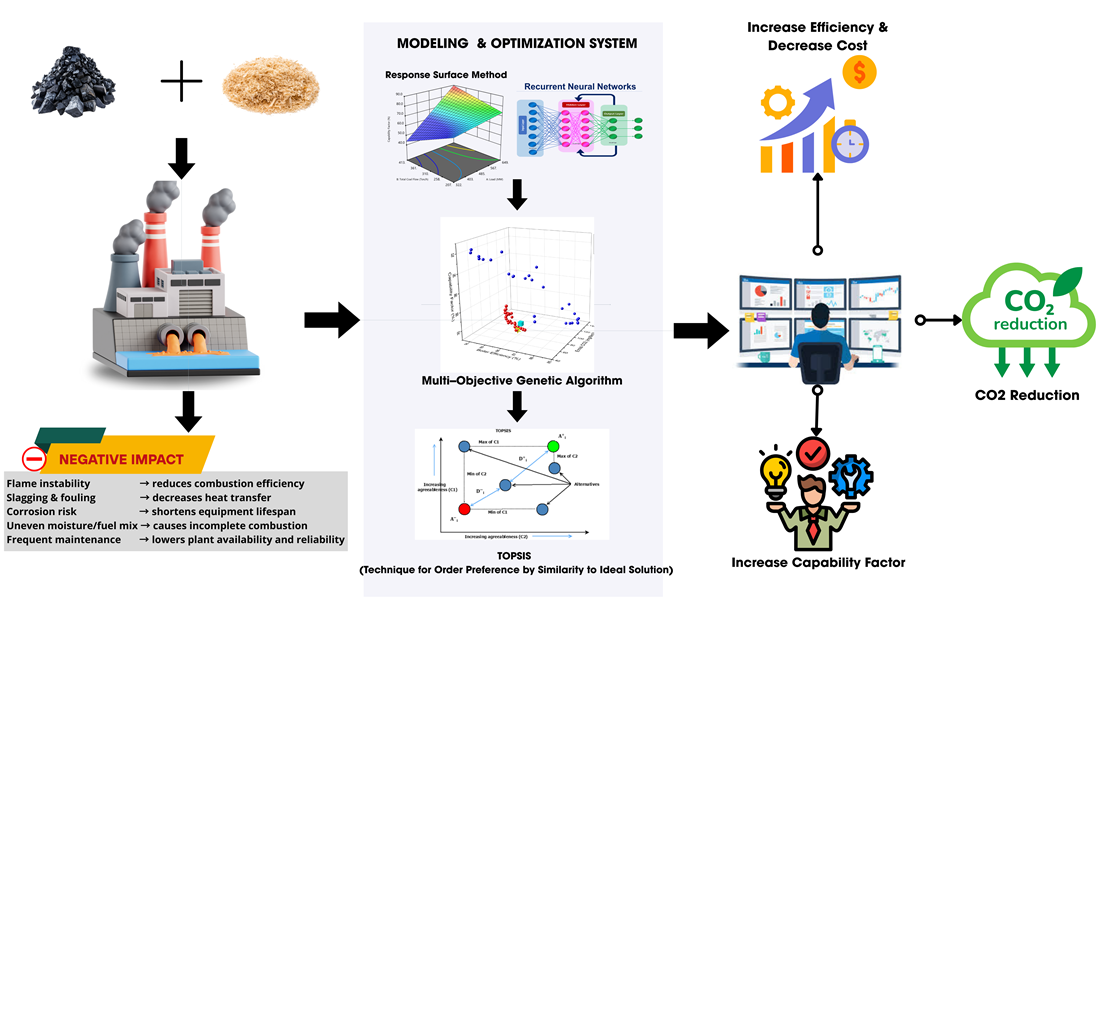

Indonesia has demonstrated a firm commitment to achieving Net Zero Emissions (NZE) by 2060. The implementation of diverse strategies, such as the application of biomass co-firing technology in coal-based steam power plants, demonstrates this commitment. This study focuses on the 660 MW supercritical coal-fired boiler as the object of investigation. The key problem addressed in this research is the unstable combustion performance due to the dynamic and nonlinear interactions among operational variables under biomass co-firing conditions. These fluctuations can negatively impact boiler efficiency, CO2 emissions, and the plant’s capability factor. The study proposes a dynamic multi-objective optimization framework using a Recurrent Neural Network (RNN), Response Surface Methodology (RSM), and a Multi-Objective Genetic Algorithm (MOGA) to enhance performance reliability and support Indonesia’s transition to cleaner energy sources.

The findings indicate that the RNN model exhibited superior prediction accuracy compared to the RSM, with a Root Mean Square Error (RMSE) value of 0.1523% for boiler efficiency, 1.6993% for CO2 emissions, and 0.5284% for the capability factor. The MOGA optimization exhibited an enhancement in boiler efficiency from 86.6793% to 87.32%, a reduction in CO2 emissions from 114.213 mg/Nm3 to 53.972 mg/Nm3, and an augmentation in the capability factor from 87.9% to 89.32%. Furthermore, coal consumption is reduced to 51,524 tons per hour, which can generate operational cost savings of IDR 1.34 billion per day.

The RNN and MOGA-based approaches have been demonstrated to be more effective than RSM for optimizing boiler combustion. This method is important for developing a strategy to improve the efficiency of the combustion process in boilers in coal-fired power plants. It will also help support the transition to clean energy and achieve the NZE 2060 target

References

- World Energy Outlook 2023. IEA. Available at: https://www.iea.org/reports/world-energy-outlook-2023

- Demirbaş, A. (2003). Sustainable cofiring of biomass with coal. Energy Conversion and Management, 44 (9), 1465–1479. https://doi.org/10.1016/s0196-8904(02)00144-9

- Eriksson, O., Finnveden, G., Ekvall, T., Björklund, A. (2007). Life cycle assessment of fuels for district heating: A comparison of waste incineration, biomass- and natural gas combustion. Energy Policy, 35 (2), 1346–1362. https://doi.org/10.1016/j.enpol.2006.04.005

- Gil, M. V., Rubiera, F. (2019). Coal and biomass cofiring. New Trends in Coal Conversion, 117–140. https://doi.org/10.1016/b978-0-08-102201-6.00005-4

- Nawaz, Z., Ali, U. (2020). Techno-economic evaluation of different operating scenarios for indigenous and imported coal blends and biomass co-firing on supercritical coal fired power plant performance. Energy, 212, 118721. https://doi.org/10.1016/j.energy.2020.118721

- Damstedt, B., Pederson, J. M., Hansen, D., Knighton, T., Jones, J., Christensen, C. et al. (2007). Biomass cofiring impacts on flame structure and emissions. Proceedings of the Combustion Institute, 31 (2), 2813–2820. https://doi.org/10.1016/j.proci.2006.07.155

- De, S., Assadi, M. (2009). Impact of cofiring biomass with coal in power plants – A techno-economic assessment. Biomass and Bioenergy, 33 (2), 283–293. https://doi.org/10.1016/j.biombioe.2008.07.005

- Roni, M. S., Chowdhury, S., Mamun, S., Marufuzzaman, M., Lein, W., Johnson, S. (2017). Biomass co-firing technology with policies, challenges, and opportunities: A global review. Renewable and Sustainable Energy Reviews, 78, 1089–1101. https://doi.org/10.1016/j.rser.2017.05.023

- Śladewski, Ł., Wojdan, K., Świrski, K., Janda, T., Nabagło, D., Chachuła, J. (2017). Optimization of combustion process in coal-fired power plant with utilization of acoustic system for in-furnace temperature measurement. Applied Thermal Engineering, 123, 711–720. https://doi.org/10.1016/j.applthermaleng.2017.05.078

- Yao, Z., Romero, C., Baltrusaitis, J. (2023). Combustion optimization of a coal-fired power plant boiler using artificial intelligence neural networks. Fuel, 344, 128145. https://doi.org/10.1016/j.fuel.2023.128145

- Nunes, L. J. R., Matias, J. C. O., Catalão, J. P. S. (2016). Biomass combustion systems: A review on the physical and chemical properties of the ashes. Renewable and Sustainable Energy Reviews, 53, 235–242. https://doi.org/10.1016/j.rser.2015.08.053

- Setiawan, A. A. R., Sofyan Munawar, S., Ishizaki, R., Putra, A. S., Ariesca, R., Sidiq, A. N. et al. (2024). Optimizing biomass supply for cofiring at power plants to minimize environmental impact: A case of oil palm empty fruit bunches in West Java. Fuel, 367, 131359. https://doi.org/10.1016/j.fuel.2024.131359

- Wang, H., Yan, Y., Li, Z., Cao, Z., Fu, Y., Zhou, Z., Zhao, D. (2025). Carbon mitigation potential and economic benefits of biomass co-firing in coal-fired power plants: A case study in Nanjing, China. Energy, 314, 134262. https://doi.org/10.1016/j.energy.2024.134262

- Bhuiyan, A. A., Blicblau, A. S., Islam, A. K. M. S., Naser, J. (2018). A review on thermo-chemical characteristics of coal/biomass co-firing in industrial furnace. Journal of the Energy Institute, 91 (1), 1–18. https://doi.org/10.1016/j.joei.2016.10.006

- Tokarski, S., Głód, K., Ściążko, M., Zuwała, J. (2015). Comparative assessment of the energy effects of biomass combustion and co-firing in selected technologies. Energy, 92, 24–32. https://doi.org/10.1016/j.energy.2015.06.044

- Xu, W., Huang, Y., Song, S. (2024). On-line combustion optimization framework for coal-fired boiler combining improved cultural algorithm, deep learning, multi-objective evolutionary algorithm with improved case-based reasoning technology. Fuel, 358, 130225. https://doi.org/10.1016/j.fuel.2023.130225

- Muhammad Ashraf, W., Moeen Uddin, G., Muhammad Arafat, S., Afghan, S., Hassan Kamal, A., Asim, M. et al. (2020). Optimization of a 660 MWe Supercritical Power Plant Performance – A Case of Industry 4.0 in the Data-Driven Operational Management Part 1. Thermal Efficiency. Energies, 13 (21), 5592. https://doi.org/10.3390/en13215592

- Box, G. E. P., Wilson, K. B. (1951). On the Experimental Attainment of Optimum Conditions. Journal of the Royal Statistical Society Series B: Statistical Methodology, 13 (1), 1–38. https://doi.org/10.1111/j.2517-6161.1951.tb00067.x

- Montgomery, D. (2019). Design and Analysis of Experiments. Wiley, 688.

- Jensen, W. A. (2017). Response Surface Methodology: Process and Product Optimization Using Designed Experiments 4th edition. Journal of Quality Technology, 49 (2), 186–188. https://doi.org/10.1080/00224065.2017.11917988

- Skovgaard, L. T. (2000). Applied regression analysis. 3rd edn. N. R. Draper and H. Smith, Wiley, New York, 1998. No. of pages: xvii+706. Price: £45. ISBN 0‐471‐17082‐8. Statistics in Medicine, 19 (22), 3136–3139. https://doi.org/10.1002/1097-0258(20001130)19:22<3136::aid-sim607>3.3.co;2-h

- Antony, J. (2014). Design of Experiments for Engineers and Scientists. Elsevier. https://doi.org/10.1016/c2012-0-03558-2

- Galintin, O., Rasit, N., Hamzah, S. (2020). Production and Characterization of Eco Enzyme Produced from Fruit and Vegetable Wastes and its Influence on the Aquaculture Sludge. Biointerface Research in Applied Chemistry, 11 (3), 10205–10214. https://doi.org/10.33263/briac113.1020510214

- Garg, S., Shariff, A. M., Shaikh, M. S., Lal, B., Suleman, H., Faiqa, N. (2017). Experimental data, thermodynamic and neural network modeling of CO2 solubility in aqueous sodium salt of l -phenylalanine. Journal of CO2 Utilization, 19, 146–156. https://doi.org/10.1016/j.jcou.2017.03.011

- Ji, Y., Kang, Z., Liu, X. (2021). The data filtering based multiple‐stage Levenberg–Marquardt algorithm for Hammerstein nonlinear systems. International Journal of Robust and Nonlinear Control, 31 (15), 7007–7025. https://doi.org/10.1002/rnc.5675

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Mohamad Arwan Efendy, Ahmad Syihan Auzani, Sholahudin Sholahudin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.