Providing technical and algorithmical support to the predictable properties of honeycomb filler obtained by additive processes

DOI:

https://doi.org/10.15587/1729-4061.2025.329745Keywords:

mechanical characteristics and accuracy of 3-D printing, cellular systems, additive manufacturing defects, additive process reliability modelsAbstract

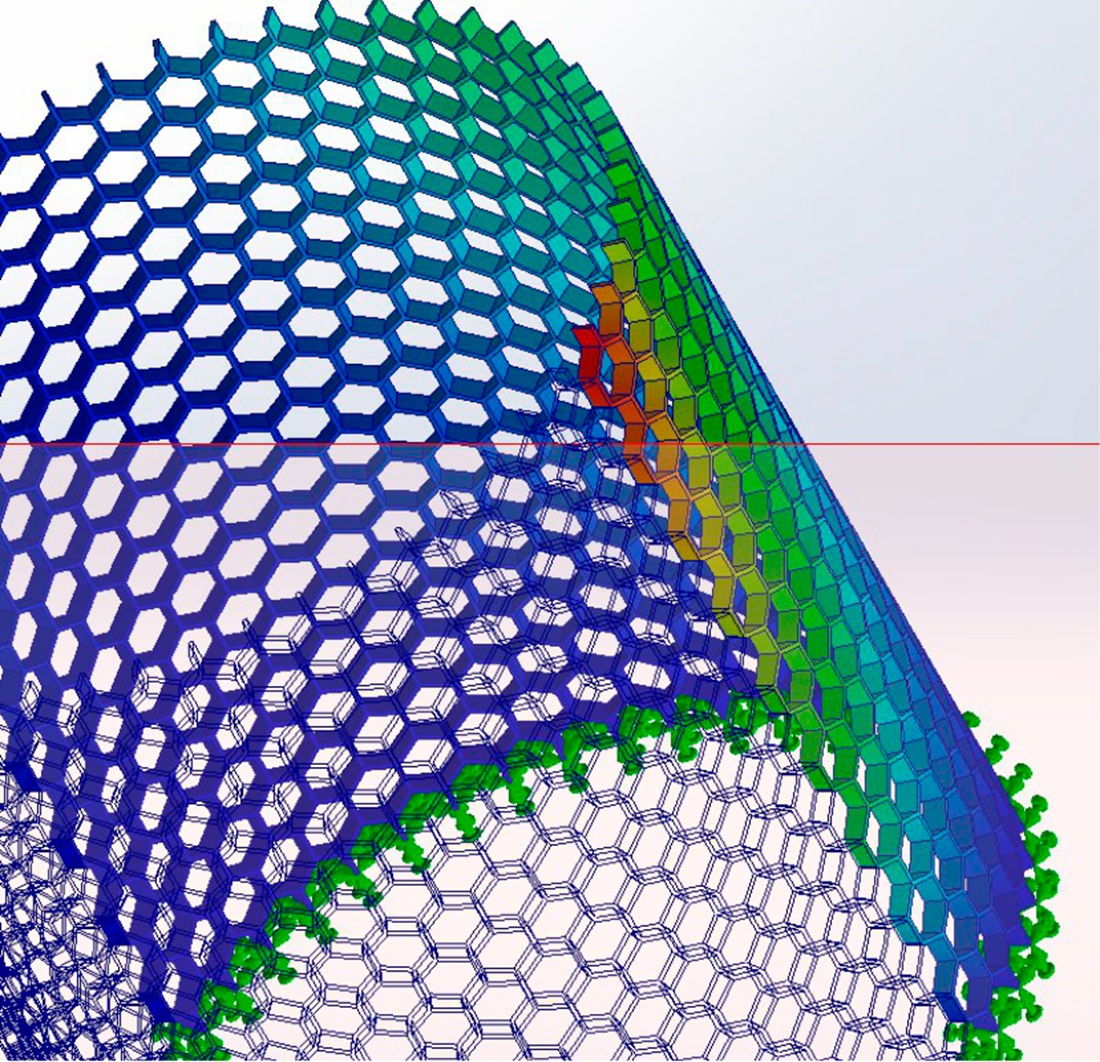

The object of this study is the FDM process underlying the 3D printing of thin-walled honeycomb-type shells. A solution to the problem of manufacturing a honeycomb filler for a sandwich panel or a panel as a whole, including a curved one, is based on the built model of the process parametric and functional reliability. To this end, the printer dynamics, the behavior of a non-rigid workpiece, and the peculiarities of filament feeding during printing have been analyzed in detail. It has been shown that the predicted mechanical properties, in particular, [σ]x,y,z, are determined by the conditions of extrudate laying and the adhesive bonds formed between its elements, both in the laying plane and between layers, and depend directly on the laying density and on a number of dynamic and thermal phenomena occurring in the mating area. The layout density parameter ρ can be used as a factor in the strength characteristics of the finished article.

The application of rational conditions for the movement of the print head, certain features of the contour traversal, the use of supporting elements, and the correct positioning of the part on the printer’s desktop allows for sufficiently reliable reproduction of cellular shell products with maximum strength.

It has been proven that the accuracy of basic dimensions of the designed structures corresponds to accuracy quality 11...12 according to engineering standards, which is acceptable for a wide range of applications. The wall thickness of the cellular elements is determined by the filament laying modes, which includes such parameters as extrusion speed, contour traversal speed and acceleration, extrusion temperature, and stacking pitch, but is not less than 1.5 times the diameter of the extruder nozzle. Such geometric parameters provide reasonable strength and rigidity for articles at operation while minimizing the weight of the honeycomb.

It has been established that cellular elements should be printed with the use of additional support means; at the same time, the latter do not exclude the occurrence of a certain number of defects whose evolution is not stable and whose presence must be taken into account when predicting the mechanical properties of the finished article

References

- Castanie, B., Bouvet, C., Ginot, M. (2020). Review of composite sandwich structure in aeronautic applications. Composites Part C: Open Access, 1, 100004. https://doi.org/10.1016/j.jcomc.2020.100004

- Ashraf, W., Ishak, M. R., M. Y. M., Z., Yidris, N., Ya’Acob, A. M. (2021). Investigation of Mechanical Properties of Honeycomb Sandwich Structure with Kenaf/glass Hybrid Composite Facesheet. Journal of Natural Fibers, 19 (13), 4923–4937. https://doi.org/10.1080/15440478.2020.1870637

- Gill, E., D’Amico, S., Montenbruck, O. (2007). Autonomous Formation Flying for the PRISMA Mission. Journal of Spacecraft and Rockets, 44 (3), 671–681. https://doi.org/10.2514/1.23015

- Bollen, P., Quiévy, N., Bailly, C., Huynen, I., Pardoen, T. (2014). Multifunctional sandwich structure for electromagnetic absorption and mechanical performances. 16th European Conference on Composite Materials (ECCM16).

- Tian, X., Todoroki, A., Liu, T., Wu, L., Hou, Z., Ueda, M. et al. (2022). 3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective. Chinese Journal of Mechanical Engineering: Additive Manufacturing Frontiers, 1 (1), 100016. https://doi.org/10.1016/j.cjmeam.2022.100016

- Khaleelullah, A., Basha, Sk. J., Rangavittal, H. K. (2012). Design and Analysis of Propellant Tanks Support Structure for an Advanced Spacecraft. International Journal of Applied Research in Mechanical Engineering, 194–200. https://doi.org/10.47893/ijarme.2012.1035

- Wlodarczyk, P. (2001). Modelarstwo lotnicze i kosmiczne. Warszawa, 384.

- Chen, Y., Li, T., Jia, Z., Scarpa, F., Yao, C.-W., Wang, L. (2018). 3D printed hierarchical honeycombs with shape integrity under large compressive deformations. Materials & Design, 137, 226–234. https://doi.org/10.1016/j.matdes.2017.10.028

- Uspensky, B., Derevianko, I., Avramov, K., Polishchuk, O., Salenko, A. (2022). Experimental and Numerical Study on Fatigue of Sandwich Plates with Honeycomb Core Manufactured by Fused Deposition Modelling. Applied Composite Materials, 29 (5), 2033–2061. https://doi.org/10.1007/s10443-022-10057-w

- Comparing properties of FDM, SLS and resin 3D-printing plastics. Available at: https://www.liqcreate.com/supportarticles/properties-fdm-sls-resin/

- Caulfield, B., McHugh, P. E., Lohfeld, S. (2007). Dependence of mechanical properties of polyamide components on build parameters in the SLS process. Journal of Materials Processing Technology, 182 (1-3), 477–488. https://doi.org/10.1016/j.jmatprotec.2006.09.007

- Popov, V. V., Fleisher, A. (2020). Hybrid additive manufacturing of steels and alloys. Manufacturing Review, 7, 6. https://doi.org/10.1051/mfreview/2020005

- Barnatt, C. (2016). 3D Printing. CreateSpace Independent Publishing Platform, 318.

- Salenko, A., Kostenko, A., Tsurkan, D., Zinchuk, A., Zagirnyak, M., Orel, V. et al. (2023). A New FDM Printer Concept for Printing Cylindrical Workpieces. Information Technology for Education, Science, and Technics, 459–483. https://doi.org/10.1007/978-3-031-35467-0_28

- Salenko, O., Derevianko, I., Samusenko, O., Avramov, K., Lithot, O., Rogulin, V. (2021). Creation of sealed strong structures of rocket and space equipment FDM printing methods by ULTEM ™ 9085 PEI plastic. Mechanics and Advanced Technologies, 5 (3), 282–293. https://doi.org/10.20535/2521-1943.2021.5.3.246626

- Salenko, A., Melnychuk, P., Lashko, E., Chencheva, O., Titarenko, O., Derevianko, I., Samusenko, A. (2020). Ensuring the functional properties of responsible structural plastic elements by means of 3-D printing. Eastern-European Journal of Enterprise Technologies, 5 (1 (107)), 18–28. https://doi.org/10.15587/1729-4061.2020.211752

- Derevianko, I. I., Avramov, K. V., Uspenskyi, B. V., Salenko, O. F. (2024). Manufacturing Technology, Experimental and Numerical Analysis of Static Bending of Three-Layer Composite Plate with Honeycomb Structure. Journal of Mechanical Engineering, 27 (3), 25–33. https://doi.org/10.15407/pmach2024.03.025

- Bobyr, M. I., Kryshchuk, M. G., Salenko, O. F., Onyshchenko, E. E., Tsurkan, D. O., Kostenko, A. O. et al. (2024). Damage Development in a Cellular Axisymmetric Tank Additive-Manufactured from Plastic Filament. Part 1. Damage Development in Cellular Axisymmetric Multilayer Shells Under Critical Mechanical Loads and Quivalent Properties of Model Layers for Stress-Strain State Estimation. Strength of Materials, 56 (3), 484–499. https://doi.org/10.1007/s11223-024-00664-2

- Chieng, B. W., Ibrahim, N. A., Then, Y. Y., Loo, Y. Y. (2016). Mechanical, thermal, and morphology properties of poly(lactic acid) plasticized with poly(ethylene glycol) and epoxidized palm oil hybrid plasticizer. Polymer Engineering & Science, 56 (10), 1169–1174. https://doi.org/10.1002/pen.24350

- Matsuzaki, R., Ueda, M., Namiki, M., Jeong, T.-K., Asahara, H., Horiguchi, K. et al. (2016). Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Scientific Reports, 6 (1). https://doi.org/10.1038/srep23058

- Schuldt, S. J., Jagoda, J. A., Hoisington, A. J., Delorit, J. D. (2021). A systematic review and analysis of the viability of 3D-printed construction in remote environments. Automation in Construction, 125, 103642. https://doi.org/10.1016/j.autcon.2021.103642

- Salenko, O., Drahobetskyi, V., Symonova, A., Onishchenko, E., Kostenko, A., Tsurkan, D., Vasiukov, D. (2024). Damage Behavior of Multilayer Axisymmetric Shells Obtained by the FDM Method. Journal of Engineering Sciences, 11 (1), D27–D35. https://doi.org/10.21272/jes.2024.11(1).d4

- Zagirnyak, M., Salenko, O., Alnusirat, W., Golovko, L., Orel, V., Kulynych, V. (2024). Increasing the Strength of Thin-walled Products Оbtained by FDM Using the Thin Surface Films. Przeglad Elektrotechniczny, 3, 289–292. https://doi.org/10.15199/48.2024.03.52

- Derevianko, I., Avramov, K., Uspensky, B., Salenko, A. (2021). Experimental analysis of the mechanical characteristics of launch vehicle parts manufactured by FDM additive technologies. Technical Mechanics, 1, 92–100. https://doi.org/10.15407/itm2021.01.092

- Kuzmych, L. V. (2021). Mechanical impacts on the reliability of complex technical systems. Technical Sciences and Technologies, 4 (14), 28–33. https://doi.org/10.25140/2411-5363-2018-4(14)-28-33

- Yakovyna, V., Matseliukh, V. (2017). Ohliad i analiz modelei nadiynosti prohramnoho zabezpechennia. Visnyk Natsionalnoho universytetu "Lvivska politekhnika". Kompiuterni nauky ta informatsiyni tekhnolohiyi, 864, 130–140. Available at: http://nbuv.gov.ua/UJRN/VNULPKNIT_2017_864_19

- Gordeev, E. G., Galushko, A. S., Ananikov, V. P. (2018). Improvement of quality of 3D printed objects by elimination of microscopic structural defects in fused deposition modeling. PLOS ONE, 13 (6), e0198370. https://doi.org/10.1371/journal.pone.0198370

- Wu, M., Phoha, V. V., Moon, Y. B., Belman, A. K. (2016). Detecting Malicious Defects in 3D Printing Process Using Machine Learning and Image Classification. Volume 14: Emerging Technologies; Materials: Genetics to Structures; Safety Engineering and Risk Analysis. https://doi.org/10.1115/imece2016-67641

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Salenko, Vasil Strutinsky, Konstantyn Avramov, Vadym Orel, Dmytro Dzhulii, Andrii Havrushkevych, Anton Kostenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.