Determining the load on a container with a truss frame during railroad transportation

DOI:

https://doi.org/10.15587/1729-4061.2025.329840Keywords:

railroad transport, universal container, container improvement, truss structure, container strength, container transportationAbstract

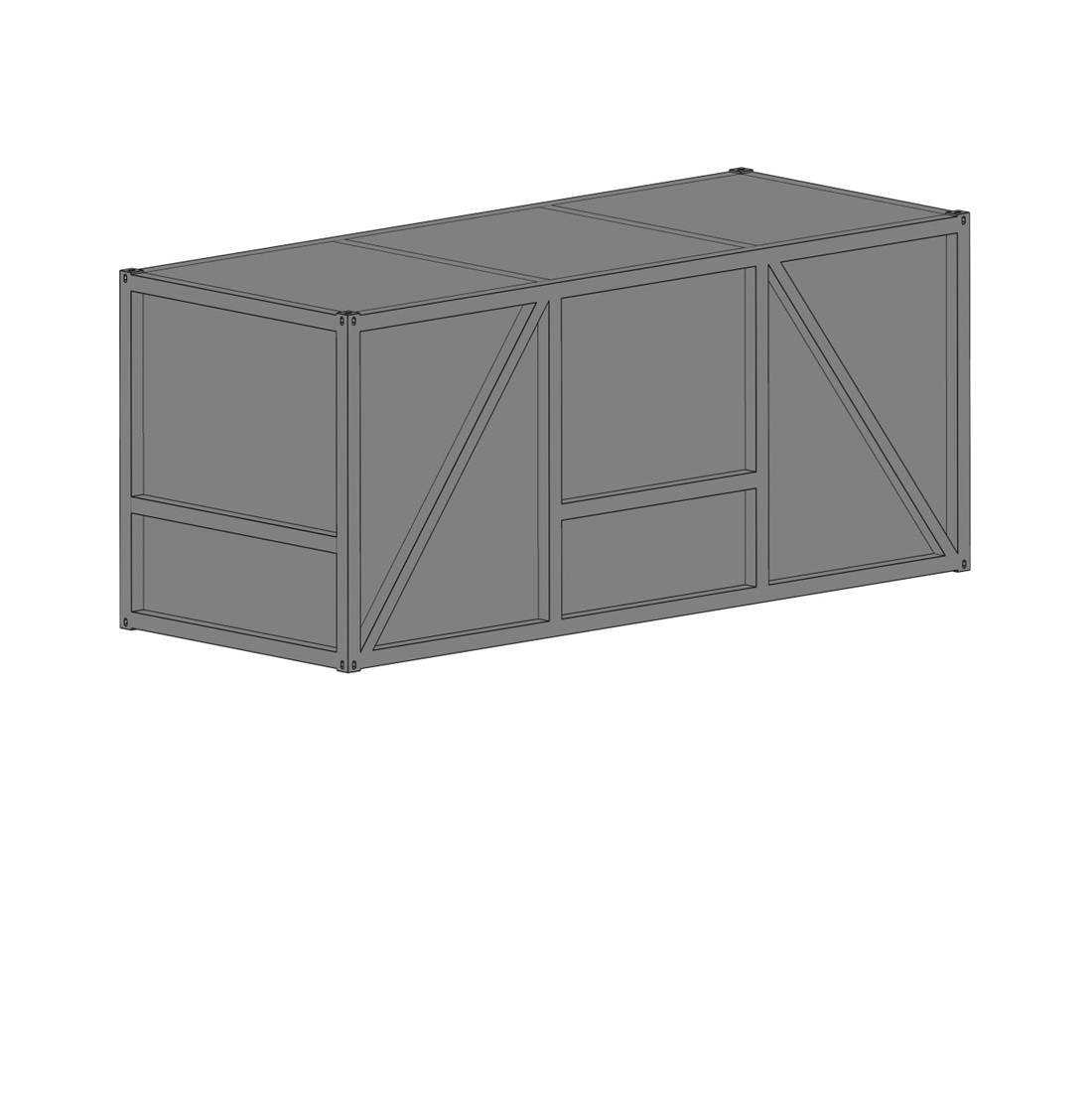

The object of this study is the processes of perception and redistribution of loads in the structure of a container with a truss frame during railroad transportation. The task addressed is to ensure the strength of the container walls under operational loads.

To provide for the strength of the container walls, it is proposed to increase the rigidity of the frame. In this case, it is assumed to install braces between the corner and vertical posts, as well as a reinforcing horizontal belt between the vertical posts.

To substantiate the proposed improvement, a calculation of the container strength was performed. Two modes of its loading were taken into account: lateral loading and vertical loading. The calculation results showed that the stresses in the container structure under the considered loading modes do not exceed the permissible ones. At the same time, the maximum stresses when the container perceives lateral loads are almost 12% lower than those that operate in a typical structure, and when perceiving vertical loads – by 5%.

In addition, a modal analysis of the container was performed as part of the study. The results of the calculation showed that the safety of its transportation from the point of view of modal analysis is observed.

A feature of the results of this study is that ensuring the strength of the container is achieved not by using high-cost materials in its design but by introducing truss components into the frame.

The scope of practical application of the research results is railroad transport. The conditions for practical use of the results are the fabrication of truss components from the same material as the container frame.

The results of the study could also contribute to compiling the recommendations for the design of new and modernization of existing containers

References

- Gerlici, J., Lovska, A., Vatulia, G., Pavliuchenkov, M., Kravchenko, O., Solčanský, S. (2023). Situational Adaptation of the Open Wagon Body to Container Transportation. Applied Sciences, 13 (15), 8605. https://doi.org/10.3390/app13158605

- Lee, C.-Y., Song, D.-P. (2017). Ocean container transport in global supply chains: Overview and research opportunities. Transportation Research Part B: Methodological, 95, 442–474. https://doi.org/10.1016/j.trb.2016.05.001

- Vatulia, G. L., Lovska, A. O., Krasnokutskyi, Y. S. (2023). Research into the transverse loading of the container with sandwich-panel walls when transported by rail. IOP Conference Series: Earth and Environmental Science, 1254 (1), 012140. https://doi.org/10.1088/1755-1315/1254/1/012140

- Zha, X., Zuo, Y. (2016). Theoretical and experimental studies on in-plane stiffness of container structure with holes. Advances in Mechanical Engineering, 8 (6). https://doi.org/10.1177/1687814016651372

- Yildiz, T. (2019). Design and Analysis of a Lightweight Composite Shipping Container Made of Carbon Fiber Laminates. Logistics, 3 (3), 18. https://doi.org/10.3390/logistics3030018

- Lovska, A., Stanovska, I., Kyryllova, V., Okorokov, A., Vernigora, R. (2024). Determining the vertical load on a container with a floor made of sandwich panels transported by a flat wagon. Eastern-European Journal of Enterprise Technologies, 6 (7 (132)), 36–44. https://doi.org/10.15587/1729-4061.2024.315059

- Rahimov, R. V., Khadjimukhametova, M. A., Rakhmatov, Z. X. (2016). Development of improved technical means for transportation fruits and vegetables. European Science Review, 1-2, 175–177. https://doi.org/10.20534/esr-16-1.2-175-177

- Jakovlev, S., Eglynas, T., Jusis, M., Jankunas, V., Voznak, M. (2025). Mitigating Container Damage and Enhancing Operational Efficiency in Global Containerisation. Sensors, 25 (7), 2019. https://doi.org/10.3390/s25072019

- Cheng, K. J., Lees, C. H., Peng, C. C. (2024). Design and structural analysis of high payload C1 container. Journal of Physics: Conference Series, 2878(1), 012012. https://doi.org/10.1088/1742-6596/2878/1/012012

- Oterkus, S., Wang, B., Oterkus, E., Galadima, Y. K., Cocard, M., Stefanos, S. et al. (2022). Structural Integrity Analysis of Containers Lost at Sea Using Finite Element Method. Sustainable Marine Structures, 4 (2), 11–17. https://doi.org/10.36956/sms.v4i2.505

- Ling, P. C. H., Tan, C. S. (2019). Numerical Simulation of ISO Freight Container Using Finite Element Modelling. Proceedings of AICCE’19, 463–469. https://doi.org/10.1007/978-3-030-32816-0_31

- Kondratiev, A., Píštěk, V., Smovziuk, L., Shevtsova, M., Fomina, A., Kučera, P., Prokop, A. (2021). Effects of the Temperature-Time Regime of Curing of Composite Patch on Repair Process Efficiency. Polymers, 13 (24), 4342. https://doi.org/10.3390/polym13244342

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. https://doi.org/10.1177/0954409715593971

- Lee, W. G., Kim, J.-S., Sun, S.-J., Lim, J.-Y. (2016). The next generation material for lightweight railway car body structures: Magnesium alloys. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232 (1), 25–42. https://doi.org/10.1177/0954409716646140

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252.

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172.

- Gerlici, J., Lovska, A., Kozáková, K. (2025). Research into the Longitudinal Loading of an Improved Load-Bearing Structure of a Flat Car for Container Transportation. Designs, 9 (1), 12. https://doi.org/10.3390/designs9010012

- Golovanevskiy, V., Kondratiev, A. (2021). Elastic Properties of Steel-Cord Rubber Conveyor Belt. Experimental Techniques, 45 (2), 217–226. https://doi.org/10.1007/s40799-021-00439-3

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Ravlyuk, V., Harusinec, J. (2023). Studying the load of composite brake pads under high-temperature impact from the rolling surface of wheels. EUREKA: Physics and Engineering, 4, 155–167. https://doi.org/10.21303/2461-4262.2023.002994

- Koshel, O., Sapronova, S., Kara, S. (2023). Revealing patterns in the stressed-strained state of load-bearing structures in special rolling stock to further improve them. Eastern-European Journal of Enterprise Technologies, 4 (7 (124)), 30–42. https://doi.org/10.15587/1729-4061.2023.285894

- Gerlici, J., Lovska, A. (2024). Study of the Strength of the Open Wagon Hatch Door with Rectangular Corrugations under Static Loads. Communications - Scientific Letters of the University of Zilina, 26 (3), B216–B225. https://doi.org/10.26552/com.c.2024.039

- Gerlici, J., Lovska, A., Pavliuchenkov, M. (2024). Study of the Dynamics and Strength of the Detachable Module for Long Cargoes under Asymmetric Loading Diagrams. Applied Sciences, 14 (8), 3211. https://doi.org/10.3390/app14083211

- Gerlici, J., Lovska, A., Pavliuchenkov, M., Harušinec, J. (2024). Investigation of the Strength and Dynamic Load on a Wagon Covered with Tarpaulin for 1520 mm Gauge Lines. Applied Sciences, 14 (15), 6810. https://doi.org/10.3390/app14156810

- Stoilov, V., Slavchev, S., Maznichki, V., Purgic, S. (2023). Method for Theoretical Assessment of Safety against Derailment of New Freight Wagons. Applied Sciences, 13 (23), 12698. https://doi.org/10.3390/app132312698

- Lovska, A., Gerlici, J., Dižo, J., Ishchuk, V. (2023). The Strength of Rail Vehicles Transported by a Ferry Considering the Influence of Sea Waves on Its Hull. Sensors, 24 (1), 183. https://doi.org/10.3390/s24010183

- Dižo, J., Blatnický, M., Harušinec, J., Suchánek, A. (2022). Assessment of Dynamics of a Rail Vehicle in Terms of Running Properties While Moving on a Real Track Model. Symmetry, 14 (3), 536. https://doi.org/10.3390/sym14030536

- Soukup, J., Skočilas, J., Skočilasová, B., Dižo, J. (2017). Vertical Vibration of Two Axle Railway Vehicle. Procedia Engineering, 177, 25–32. https://doi.org/10.1016/j.proeng.2017.02.178

- Goolak, S., Sapronova, S., Tkachenko, V., Riabov, I., Batrak, Y. (2020). Improvement of the model of power losses in the pulsed current traction motor in an electric locomotive. Eastern-European Journal of Enterprise Technologies, 6 (5 (108)), 38–46. https://doi.org/10.15587/1729-4061.2020.218542

- Domin, Yu. V., Cherniak, H. Yu. (2003). Osnovy dynamiky vahoniv. Kyiv: KUETT, 269.

- Goolak, S., Tkachenko, V., Bureika, G., Vaičiūnas, G. (2021). Method of spectral analysis of traction current of ac electric locomotives. Transport, 35 (6), 658–668. https://doi.org/10.3846/transport.2020.14242

- Goolak, S., Liubarskyi, B., Sapronova, S., Tkachenko, V., Riabov, Ie. (2021). Refined Model of Asynchronous Traction Electric Motor of Electric Locomotive. The proceedings of the 25th International Scientific Conference Transport Means 2021 - Sustainability: Research and Solutions. Kaunas, 455–460.

- Steišūnas, S., Dižo, J., Bureika, G., Žuraulis, V. (2017). Examination of Vertical Dynamics of Passenger Car with Wheel Flat Considering Suspension Parameters. Procedia Engineering, 187, 235–241. https://doi.org/10.1016/j.proeng.2017.04.370

- Dizo, J., Blatnicky, M. (2019). Evaluation of Vibrational Properties of a Three-wheeled Vehicle in Terms of Comfort. Manufacturing Technology, 19 (2), 197–203. https://doi.org/10.21062/ujep/269.2019/a/1213-2489/mt/19/2/197

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Alyona Lovska, Oksana Zharovа, Arsen Muradian, Valeriia Kyryllova, Yevhen Pelypenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.