Визначення раціональних технологічних режимів обробки з метою одержання оптимльних експлуатацйних характеристик поверхневого шару, отриманого електроіскровим легуванням з використанням твердосплавних електродів

DOI:

https://doi.org/10.15587/1729-4061.2025.331878Ключові слова:

електроіскрове легування, тверді сплави, трибологічні дослідження, спектральний аналіз, мікротвердість, зношуванняАнотація

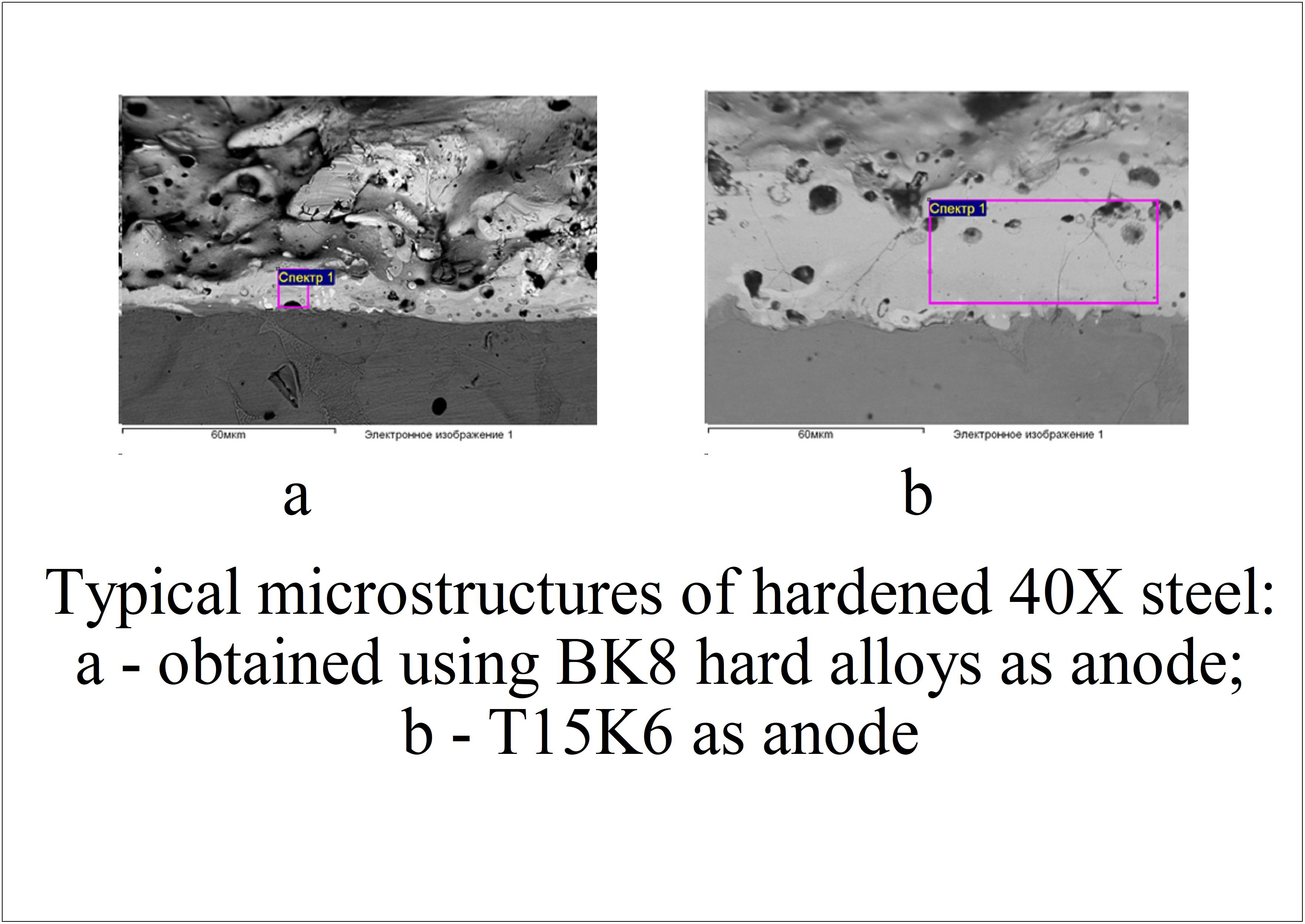

Об’єкт дослідження – зносостійкість поверхонь після електроіскрового легування при контакті з пружнозакріпленими зернами абразиву. Проблема, що вирішувалась в роботі, пов'язана з відсутністю технологічних режимів для електроіскрової обробки, зокрема для твердих сплавів Т15К6 і ВК8. Визначено раціональний режим, за якого отримувалися зразки з оптимальним профілнм поверхні, однорідною структурою та мінімальними внутрішніми дефектами.

Вибір способу обробки швидкозношуваних поверхонь методом електроіскрового легування обумовлений його простотою та доступністю.

В якості електродів можуть бути використані відходи. З окрема твердосплпвні пластинки ріжучого інструменту, які вийшли з ладу. Одночсно залишається ряд невирішених питань, пов’язаних з вибором оптимальних режимів обробки, які б забезпечили високу зносостійкість оброблених поверхонь.

Запропоновано сосіб випробовування оброблених деталей на зношування. Було встановлено, що найвищою прогнозованою зносостійкістю володітимуть деталі, оброблені методом електроіскровог легування (ЕІЛ) із застосуванням електрода ВК8, ємність конденсаторної батареї 330 ± 30 мкФ, частота вібрації електроду 125 ± 25 Гц. Вони поєднують високу поверхневу мікротвердість (13,5 МПа) та залишкові напруження стиску в нанесеному шарі (–90 МПа).

Результати пояснюються з точки зору фізико-механічних процесів, що відбуваються в металі під час електроіскрового легування. Ці умови створювалися різними значеннями технологічних параметрів. Особливістю результатів є те, що було встновлено, що значний вплив на експлуатаційні параметри має не тільки твердість нанасеного шару, але і величина внутрішніх напружень в цьому шарі. Практичне застосувння: електроіскрове легування може стати альтернативною технологією зміцнення поверхонь деталей, які працюють в умовах контакту з абразивом (машинобудування, медицина)

Посилання

- Tarelnyk, V., Konoplianchenko, I., Tarelnyk, N., Kozachenko, A. (2019). Modeling Technological Parameters for Producing Combined Electrospark Deposition Coatings. Materials Science Forum, 968, 131–142. https://doi.org/10.4028/www.scientific.net/msf.968.131

- Katinas, E., Jankauskas, V., Kazak, N., Michailov, V. (2019). Improving Abrasive Wear Resistance for Steel Hardox 400 by Electro-Spark Deposition. Journal of Friction and Wear, 40 (1), 100–106. https://doi.org/10.3103/s1068366619010070

- Lu, K., Zhu, J., Ge, W., Hui, X. (2022). Progress on New Preparation Methods, Microstructures, and Protective Properties of High-Entropy Alloy Coatings. Coatings, 12 (10), 1472. https://doi.org/10.3390/coatings12101472

- Zhengchuan, Z., Guanjun, L., Konoplianchenko, I., Tarelnyk, V. B., Zhiqin, G., Xin, D. (2022). A review of the electro-spark deposition technology. Bulletin of Sumy National Agrarian University. The Series: Mechanization and Automation of Production Processes, 2 (44), 45–53. https://doi.org/10.32845/msnau.2021.2.10

- Wang, J., Zhang, M., Dai, S., Zhu, L. (2023). Research Progress in Electrospark Deposition Coatings on Titanium Alloy Surfaces: A Short Review. Coatings, 13 (8), 1473. https://doi.org/10.3390/coatings13081473

- Leo, P., Renna, G., Casalino, G. (2017). Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Applied Sciences, 7 (9), 945. https://doi.org/10.3390/app7090945

- Cao, G., Zhang, X., Tang, G., Ma, X. (2019). Microstructure and Corrosion Behavior of Cr Coating on M50 Steel Fabricated by Electrospark Deposition. Journal of Materials Engineering and Performance, 28 (7), 4086–4094. https://doi.org/10.1007/s11665-019-04148-2

- Salmaliyan, M., Malek Ghaeni, F., Ebrahimnia, M. (2017). Effect of electro spark deposition process parameters on WC-Co coating on H13 steel. Surface and Coatings Technology, 321, 81–89. https://doi.org/10.1016/j.surfcoat.2017.04.040

- Jiao, Z., Peterkin, S., Felix, L., Liang, R., Oliveira, J. P., Schell, N. et al. (2018). Surface Modification of 304 Stainless Steel by Electro-Spark Deposition. Journal of Materials Engineering and Performance, 27 (9), 4799–4809. https://doi.org/10.1007/s11665-018-3579-0

- Tarelnyk, V., Martsynkovskyy, V., Gaponova, O., Konoplianchenko, I., Dovzyk, M., Tarelnyk, N., Gorovoy, S. (2017). New sulphiding method for steel and cast iron parts. IOP Conference Series: Materials Science and Engineering, 233, 012049. https://doi.org/10.1088/1757-899x/233/1/012049

- Kozak, F. V., Prunko, I. B., Fedenko, V. Y., Gladun, M. R. (2024). Optimization of the process of application of electrospark coatings when strengthening automotive parts of the “shaft” type. Oil and Gas Power Engineering, 2 (40), 66–72. https://doi.org/10.31471/1993-9868-2023-2(40)-66-72

- Kryshtopa, S., Kryshtopa, L., Bogatchuk, I., Prunko, I., Melnyk, V. (2017). Examining the effect of triboelectric phenomena on wear-friction properties of metal-polymeric frictional couples. Eastern-European Journal of Enterprise Technologies, 1 (5 (85)), 40–45. https://doi.org/10.15587/1729-4061.2017.91615

- Kryshtopa, S. І., Petryna, D. Yu., Bogatchuk, I. М., Prun’ko, I. B., Меl’nyk, V. М. (2017). Surface Hardening of 40KH Steel by Electric-Spark Alloying. Materials Science, 53 (3), 351–358. https://doi.org/10.1007/s11003-017-0082-y

- Kryshtopa, S., Kozhevnykov, A., Panchuk, M., Kryshtopa, L. (2018). Influence of triboelectric processes on friction characteristics of brake units of technological transport. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 3, 87–93. https://doi.org/10.29202/nvngu/2018-3/10

- Kryshtopa, S. I., Prun’ko, I. B., Dolishnii, B. V., Panchuk, M. V., Bogatchuk, I. M., Mel’nyk, V. M. (2019). Regularities of Wear of Metal-Polymer Friction Couples Under the Influence of Tribocurrents. Materials Science, 55 (2), 193–200. https://doi.org/10.1007/s11003-019-00288-x

- Hvozdets’kyi, V. М., Sirak, Ya. Ya., Zadorozhna, Kh. R., Dem’yanchuk, Ya. М. (2018). Influence of the Size of Drops and the Velocity of Flow on the Structure and Properties of Electric-Arc Coatings. Materials Science, 53 (5), 702–708. https://doi.org/10.1007/s11003-018-0126-y

- Prysyazhnyuk, P., Ivanov, O., Matvienkiv, O., Marynenko, S., Korol, O., Koval, I. (2022). Impact and abrasion wear resistance of the hardfacings based on high-manganese steel reinforced with multicomponent carbides of Ti-Nb-Mo-V-C system. Procedia Structural Integrity, 36, 130–136. https://doi.org/10.1016/j.prostr.2022.01.014

- Rukanskis, M. (2019). Control of Metal Surface Mechanical and Tribological Characteristics Using Cost Effective Electro-Spark Deposition. Surface Engineering and Applied Electrochemistry, 55 (5), 607–619. https://doi.org/10.3103/s1068375519050107

- Ribalko, A. V., Sahin, O., Korkmaz, K. (2009). A modified electrospark alloying method for low surface roughness. Surface and Coatings Technology, 203 (23), 3509–3515. https://doi.org/10.1016/j.surfcoat.2009.05.002

- Bembenek, M., Kopei, V., Ropyak, L., Levchuk, K. (2023). Stressed State of Chrome Parts During Diamond Burnishing. Metallofizika I Noveishie Tekhnologii, 45 (2), 239–250. https://doi.org/10.15407/mfint.45.02.0239

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Ihor Prunko, Tetyana Voitsekhivska, Yaroslav Dem’yanchuk

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.