The effective process of waste cooking oil biodiesel production by interesterification with reaction using curcumin biocatalyst

DOI:

https://doi.org/10.15587/1729-4061.2025.333086Keywords:

interesterification, biodiesel, curcumin biocatalyst, crude yield, methyl esterAbstract

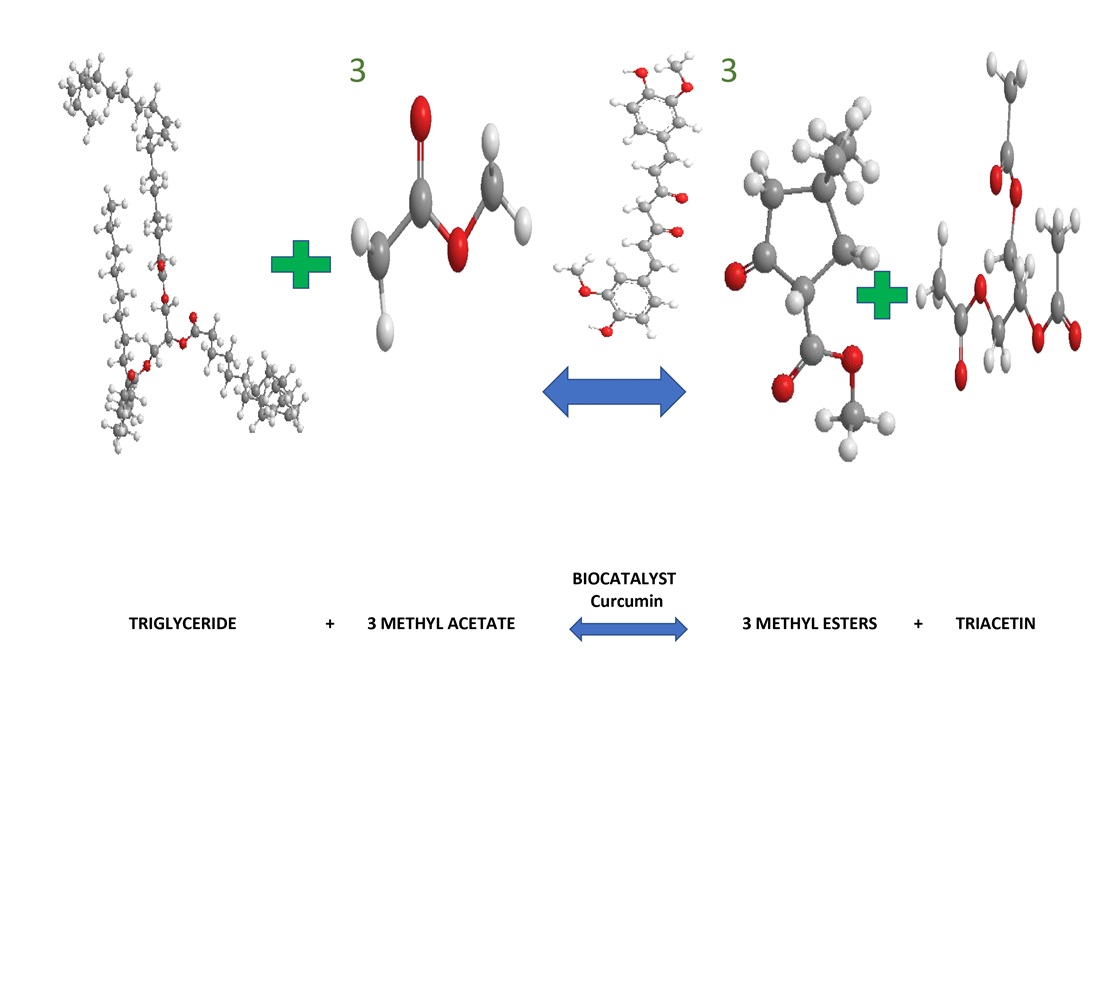

Biodiesel is a renewable energy source that can replace fossil fuels. Used cooking oil is the most relevant biodiesel feedstock because it is a waste product. The interesterification process for biodiesel production uses a catalyst that requires separation at the end of the reaction, making it less effective. A more effective and economical biodiesel production process using waste raw materials, without the separation of by-products and catalysts, is needed to overcome this problem. Organic aromatic compound biocatalysts are environmentally friendly and relatively inexpensive. Compound biocatalysts eliminate the need for a separation process and any residue left in the biodiesel can be beneficial, as these substances act as antioxidants preventing an increase in oxidation number. In this context, curcumin is an organic aromatic compound with two aromatic groups. Therefore, this research obtains rational conditions for the interesterification reaction of waste cooking oil with curcumin biocatalyst. The operating conditions included 250 grams of waste cooking oil, the mass of curcumin biocatalyst was 0.5, 1, 1.5, 2, and 2.5%, 300 rpm stirring speed, mole ratio of methyl acetate oil was 1:6 and 1:12, reaction temperature 60°C as well as reaction time of 15, 30, 45, 60, 75, 90 and 105 minutes. The results show that the highest crude yield was obtained at 91.74% in the interesterification reaction of waste cooking oil with a curcumin biocatalyst concentration of 2.5% at a reaction time of 105 minutes and the mole ratio of oil:methyl acetate = 1:6. A density value of 0.884 g/ml and an acid number of 0.224 mg KOH/g were obtained which met SNI 7182-2015 under these conditions. In addition, the outcome of the GC-MS analysis shows that the dominant methyl ester component formed was hexadecanoic acid, 1-methylethyl ester

References

- Daryono, E. D., Sinaga, E. J. (2017). Rapid in situ transesterification of papaya seeds to biodiesel with the aid of co-solvent. International Journal of Renewable Energy Research, 7 (1). https://doi.org/10.20508/ijrer.v7i1.5275.g6998

- Calero, J., Luna, D., Sancho, E. D., Luna, C., Bautista, F. M., Romero, A. A. et al. (2015). An overview on glycerol-free processes for the production of renewable liquid biofuels, applicable in diesel engines. Renewable and Sustainable Energy Reviews, 42, 1437–1452. https://doi.org/10.1016/j.rser.2014.11.007

- Chuepeng, S., Komintarachat, C. (2018). Interesterification optimization of waste cooking oil and ethyl acetate over homogeneous catalyst for biofuel production with engine validation. Applied Energy, 232, 728–739. https://doi.org/10.1016/j.apenergy.2018.09.085

- Daryono, E. D., Wardana, I. N. G., Cahyani, C., Hamidi, N. (2021). Biodiesel production process without glycerol by-product with base catalyst: effect of reaction time and type of catalyst on kinetic energy and solubility. IOP Conference Series: Materials Science and Engineering, 1053 (1), 012058. https://doi.org/10.1088/1757-899x/1053/1/012058

- Lopes, T. I. B., Ribeiro, M. D. M. M., Ming, C. C., Grimaldi, R., Gonçalves, L. A. G., Marsaioli, A. J. (2016). Comparison of the regiospecific distribution from triacylglycerols after chemical and enzymatic interesterification of high oleic sunflower oil and fully hydrogenated high oleic sunflower oil blend by carbon-13 nuclear magnetic resonance. Food Chemistry, 212, 641–647. https://doi.org/10.1016/j.foodchem.2016.06.024

- Interrante, L., Bensaid, S., Galletti, C., Pirone, R., Schiavo, B., Scialdone, O., Galia, A. (2018). Interesterification of rapeseed oil catalysed by a low surface area tin (II) oxide heterogeneous catalyst. Fuel Processing Technology, 177, 336–344. https://doi.org/10.1016/j.fuproc.2018.05.017

- Simões, S. S., Ribeiro, J. S., Celante, D., Brondani, L. N., Castilhos, F. (2020). Heterogeneous catalyst screening for fatty acid methyl esters production through interesterification reaction. Renewable Energy, 146, 719–726. https://doi.org/10.1016/j.renene.2019.07.023

- Nunes, A. L. B., Castilhos, F. (2020). Chemical interesterification of soybean oil and methyl acetate to FAME using CaO as catalyst. Fuel, 267, 117264. https://doi.org/10.1016/j.fuel.2020.117264

- Tian, Y., Xiang, J., Verni, C. C., Soh, L. (2018). Fatty acid methyl ester production via ferric sulfate catalyzed interesterification. Biomass and Bioenergy, 115, 82–87. https://doi.org/10.1016/j.biombioe.2018.04.013

- Daryono, E. D., Wardana, I. N. G., Cahyani, C., Hamidi, N. (2022). Interesterification Process of Palm Oil Using Base Catalyst: The Effect of Stirring Speed and Type of Catalyst on Kinetic Energy and Dipole Moment. International Journal on Advanced Science, Engineering and Information Technology, 12 (4), 1580. https://doi.org/10.18517/ijaseit.12.4.12500

- Daryono, E. D. (2015). Reactive extraction process in isolation of eugenol of clove essential oil (Syzigium aromaticum) based on temperature and time process. International Journal of ChemTech Research, 8 (11), 564–569.

- Daryono, E. D., Dewi, R. K. (2022). Biodiesel from palm oil with interesterification process using bio-catalyst cajuput oil. Konversi, 11 (2). https://doi.org/10.20527/k.v11i2.13982

- Purnami, P., Wardana, I. N. G., Hamidi, N., Sasongko, M. N., Darmadi, D. (2019). The Effect of Rhodium (III) Sulfate and Clove Oil Catalysts on The Droplet Combustion Characteristics of Castor Oil. International Journal of Integrated Engineering, 11 (5), 66–71. https://doi.org/10.30880/ijie.2019.11.05.009

- Purnami, Hamidi, N., Sasongko, M. N., Widhiyanuriyawan, D., Wardana, I. N. G. (2020). Strengthening external magnetic fields with activated carbon graphene for increasing hydrogen production in water electrolysis. International Journal of Hydrogen Energy, 45 (38), 19370–19380. https://doi.org/10.1016/j.ijhydene.2020.05.148

- Suprianto, T., Winarto, Wijayanti, W., Wardana, I. N. G. (2021). Synergistic effect of curcumin and activated carbon catalyst enhancing hydrogen production from biomass pyrolysis. International Journal of Hydrogen Energy, 46 (10), 7147–7164. https://doi.org/10.1016/j.ijhydene.2020.11.211

- Willy Satrio, N., Winarto, Sugiono, Wardana, I. N. G. (2020). Hydrogen production from instant noodle wastewater by organic electrocatalyst coated on PVC surface. International Journal of Hydrogen Energy, 45 (23), 12859–12873. https://doi.org/10.1016/j.ijhydene.2020.03.002

- Ali, R. M., Elkatory, M. R., Hamad, H. A. (2020). Highly active and stable magnetically recyclable CuFe2O4 as a heterogenous catalyst for efficient conversion of waste frying oil to biodiesel. Fuel, 268, 117297. https://doi.org/10.1016/j.fuel.2020.117297

- Xie, W., Wang, H. (2020). Immobilized polymeric sulfonated ionic liquid on core-shell structured Fe3O4/SiO2 composites: A magnetically recyclable catalyst for simultaneous transesterification and esterifications of low-cost oils to biodiesel. Renewable Energy, 145, 1709–1719. https://doi.org/10.1016/j.renene.2019.07.092

- Han, Y.-Z., Hong, L., Wang, X.-Q., Liu, J.-Z., Jiao, J., Luo, M., Fu, Y.-J. (2016). Biodiesel production from Pistacia chinensis seed oil via transesterification using recyclable magnetic cellulose-based catalyst. Industrial Crops and Products, 89, 332–338. https://doi.org/10.1016/j.indcrop.2016.05.015

- Silveira Junior, E. G., Justo, O. R., Perez, V. H., Reyero, I., Serrano-Lotina, A., Campos Ramirez, L., dos Santos Dias, D. F. (2018). Extruded Catalysts with Magnetic Properties for Biodiesel Production. Advances in Materials Science and Engineering, 2018 (1). https://doi.org/10.1155/2018/3980967

- Marlina, E., Basjir, M., Ichiyanagi, M., Suzuki, T., Gotama, G. J., Anggono, W. (2020). The Role of Eucalyptus Oil in Crude Palm Oil As Biodiesel Fuel. Automotive Experiences, 3 (1), 33–38. https://doi.org/10.31603/ae.v3i1.3257

- Wardoyo, Widodo, A. S., Wijayanti, W., Wardana, I. N. G. (2021). The Role of Areca catechu Extract on Decreasing Viscosity of Vegetable Oils. The Scientific World Journal, 2021, 1–8. https://doi.org/10.1155/2021/8827427

- Soebiyakto, G., Wardana, I. N. G., Hamidi, N., Yuliati, L. (2020). Addition of bio-additive as a catalyst of burning vegetable oil influenced by 4 pole magnetic field. Eastern-European Journal of Enterprise Technologies, 2 (6 (104)), 46–55. https://doi.org/10.15587/1729-4061.2020.198308

- Daryono, E. D., Jimmy, J., Setyawati, H. (2024). Production of Biodiesel Without Catalyst Separation with Palm Oil Interesterification Process Using Essential Oil Biocatalyst. Chemistry & Chemical Technology, 18 (3), 356–362. https://doi.org/10.23939/chcht18.03.356

- Pullen, J., Saeed, K. (2015). Investigation of the factors affecting the progress of base-catalyzed transesterification of rapeseed oil to biodiesel FAME. Fuel Processing Technology, 130, 127–135. https://doi.org/10.1016/j.fuproc.2014.09.013

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Elvianto Dwi Daryono, I Komang Astana Widi, Yudi Purnomo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.