Determining the heat and mass transfer patterns in the tundish of a continuous casting machine

DOI:

https://doi.org/10.15587/1729-4061.2025.336057Keywords:

tundish, continuous casting of billets, liner, CFD modeling, SHAP analysis, machine learningAbstract

This study’s object is the thermal state of the tundish ladle in a continuous billet casting machine, aimed at prolonging the duration of the series of melts.

This paper reports the numerical modeling of the heat and mass transfer processes in the tundish ladle of a continuous billet casting machine (CCM). The model takes into account the hydrodynamics of liquid steel, as well as the temperature distribution in the multilayer lining and the ladle casing; it also makes it possible to predict local wear of the lining based on the analysis of the technological parameters of the process and the chemical composition of steel. Special attention is paid to the study of the temperature and turbulent characteristics of the flow, the residence time of the steel in the ladle, and the influence of its composition on the intensity of destruction of the lining layers.

The results make it possible to localize critical areas of thermal and mechanical overload of the ladle lining, in particular the contact zones of the liquid steel jet and the wall areas near the turbos tops, where the following are recorded: shear stress up to 275 Pa; turbulent kinetic energy over 0.14 m2/s2; and metal temperature up to 1830 K.

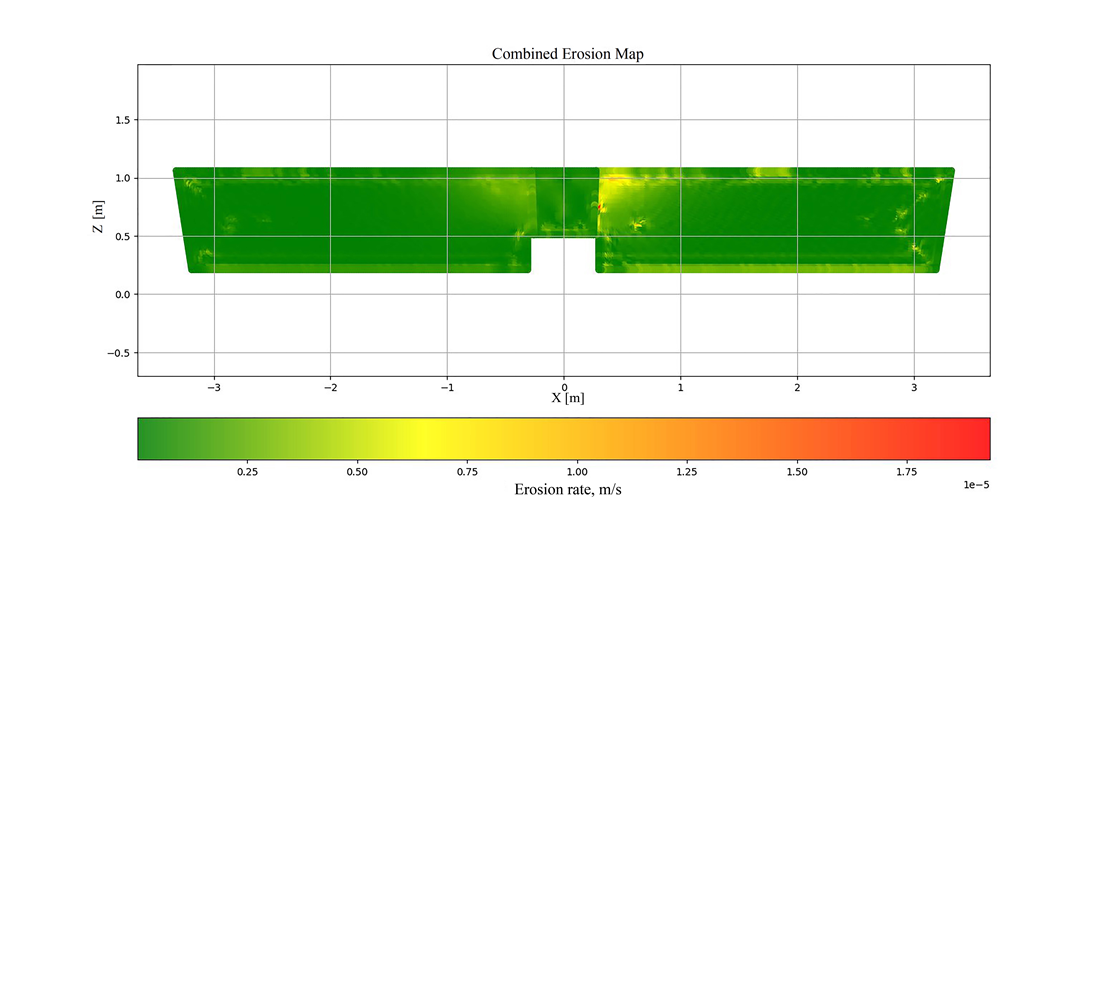

The local wear map built shows the distribution of the lining erosion rate within 2.4–4.3 mm/h depending on the hydrodynamic and chemical conditions. The predictive model combines CFD parameters, the chemical composition of steel, and the pouring speed, which showed high accuracy confirmed by the coefficient of determination R2 = 0.99937.

A feature of the result is the comprehensive combination of local flow conditions and steel composition with the erosion model, which has made it possible to give engineering-based recommendations for optimizing the ladle operating modes.

The developed predictive model of liner wear rate could be used to monitor its condition, improve ladle operating modes, and increase the reliability of the continuous casting process

References

- Wang, Q., Tan, C., Huang, A., Yan, W., Gu, H., He, Z. et al. (2021). Numerical Simulation on Refractory Wear and Inclusion Formation in Continuous Casting Tundish. Metallurgical and Materials Transactions B, 52 (3), 1344–1356. https://doi.org/10.1007/s11663-021-02097-7

- Wang, Q., Tan, C., Huang, A., Yan, W., Gu, H., He, Z. et al. (2021). Quantitative Characterization of Flow-Induced Erosion of Tundish Refractory Lining via Water Model Experiment and Numerical Simulation. Metallurgical and Materials Transactions B, 52 (5), 3265–3275. https://doi.org/10.1007/s11663-021-02254-y

- Zhang, J., Qin, B., Liu, Y., Li, Q., Zuo, X., Wang, C. et al. (2023). Multiphase flow inside a four-strand continuous casting tundish using three types of ladle shrouds. Journal of Iron and Steel Research International, 30 (6), 1171–1181. https://doi.org/10.1007/s42243-023-00982-w

- Dong, B., Lv, W., Xie, Z. (2024). Research on temperature prediction model of molten steel of tundish in continuous casting. Scientific Reports, 14 (1). https://doi.org/10.1038/s41598-024-78611-z

- Box, G. E. P., Hunter, J. S., Hunter, W. G. (2005). Statistics for Experimenters: Design, Innovation, and Discovery. Wiley, 672.

- Wang, T., Wang, J., Chen, C., Chen, L., Geng, M., Song, J. et al. (2024). Physical and Numerical Study on Right Side and Front Side Gas Blowing at Walls in a Single‐Strand Tundish. Steel Research International, 95 (9). https://doi.org/10.1002/srin.202400037

- Zhou, H., Li, H., Deng, X., Liu, B., Ji, C., Chen, B. et al. (2024). Optimization of Vortex Slag Entrainment during Ladle Teeming Process in the Continuous Casting of Automobile Outer Panel. Steel Research International, 95 (10). https://doi.org/10.1002/srin.202400322

- Cramb, A. W. (Ed.) (2018). Making, Shaping and Treating of Steel: Continuous Casting. Pittsburgh: AIST.

- Bathe, K.-J. (2006). Finite Element Procedures. Klaus-Jurgen Bathe, 1037.

- Synehin, Ye. V., Sukhovetskyi, S. V. (2022). Analytical studies and characteristics of steel refining methods in the CCM tundish. Teoriia i praktyka metalurhii, 4, 25–29. Available at: https://crust.ust.edu.ua/items/d0c7753a-eb06-4b78-9df0-82f88c18f80b

- Smirnov, O. M., Kuberskyi, S. V., Shtepan, Ye. V. (2011). Bezperervne rozlyvannia stali. Alchevsk: DonDTU, 518.

- Sigarev, E. N., Chernyatevich, A. G., Chubina, E. A. (2007). Thermodynamic andgas-dynamic aspects of the guniting of converter linings. Steel in Translation, 37 (2), 92–98. https://doi.org/10.3103/s0967091207020039

- Zovnishnia torhivlia Ukrainy tovaramy u 2021 rotsi (2022). Derzhavna sluzhba statystyky Ukrainy. Available at: https://www.ukrstat.gov.ua/express/expr2022/02/14.pdf

- Vnesok HMK v ekonomiku Ukrainy 2024 (2025). GMK Center.Available at: https://gmk.center/wp-content/uploads/2025/04/ukr_2025_Econ_Steel-impact.pdf

- Ruban, V., Stoianov, O., Niziaiev, K., Synehin, Y. (2021). Determining changes in the temperature field of a graphitized hollow electrode during metal processing periods in ladle-furnace. Eastern-European Journal of Enterprise Technologies, 2 (1 (110)), 109–115. https://doi.org/10.15587/1729-4061.2021.230002

- Launder, B. E. (1972). Lectures in mathematical models of turbulence. London: Academic Press, 169.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Ruban, Dmytro Terekhov, Oleksandr Stoianov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.