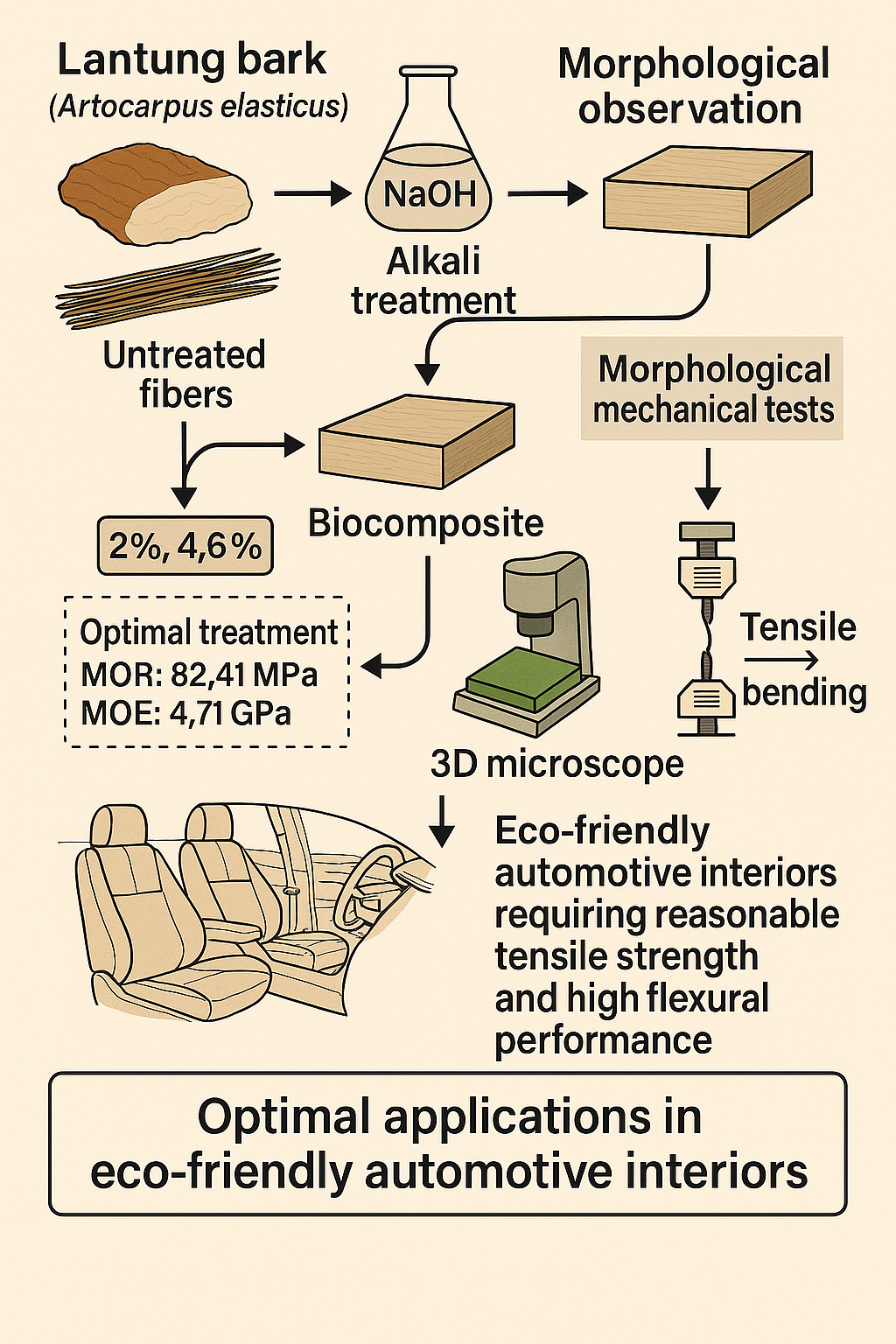

Identifying the mechanical properties and surface morphology of artocarpus elasticus fiber biocomposites due to the effect of alkali treatment for automotive applications

DOI:

https://doi.org/10.15587/1729-4061.2025.337175Keywords:

Artocarpus elasticus, biocomposites, hand lay-up, mechanical properties, morphology, sodium hydroxideAbstract

Lantung bark (Artocarpus elasticus), a natural fiber abundant in Bengkulu and other Indonesian regions, was studied as reinforcement in polyester-based biocomposites. The increasing demand for environmentally friendly materials has driven the development of natural fiber-based biocomposites as alternatives to synthetic materials. The main problem addressed is the weak interfacial bonding between untreated Lantung fibers and polymer matrices, reducing composite mechanical performance. To overcome this, fibers were treated with Sodium Hydroxide (NaOH) solutions at 2%, 4%, and 6% concentrations for 2 hours to improve surface morphology and chemical reactivity. After drying, treated fibers were fabricated into biocomposites using the hand lay-up pressing method. Testing included morphological observation via 3D microscopy and mechanical evaluation through tensile and bending tests based on ASTM standards. Results showed that 2% NaOH treatment provided the best biocomposite’s mechanical properties, with a Modulus of Rupture (MOR) of 82.41 MPa and a Modulus of Elasticity (MOE) of 4.71 GPa. These improvements are explained by effective removal of surface impurities without significant fiber damage, enhancing fiber-matrix adhesion. The distinctive feature of this study is identifying an optimal alkali concentration that maintains fiber integrity while significantly improving mechanical performance. The developed Lantung biocomposites have potential applications as eco-friendly interior or non-structural automotive components requiring moderate tensile strength and high flexural performance

References

- Yogesh, M., Hari, R. A. N. (2017). Study on Pineapple Leaves Fibre and its Polymer based Composite: A Review. International Journal of Science and Research (IJSR), 6 (1), 799–807. https://doi.org/10.21275/art20164188

- Melyna, E., Afridana, A. P. (2023). The Effect of Coffee Husk Waste Addition with Alkalisation Treatment on the Mechanical Properties of Polypropylene Composites. Equilibrium Journal of Chemical Engineering, 7 (1), 14. https://doi.org/10.20961/equilibrium.v7i1.68556

- Zin, M. H., Abdan, K., Mazlan, N., Zainudin, E. S., Liew, K. E. (2018). The effects of alkali treatment on the mechanical and chemical properties of pineapple leaf fibres (PALF) and adhesion to epoxy resin. IOP Conference Series: Materials Science and Engineering, 368, 012035. https://doi.org/10.1088/1757-899x/368/1/012035

- Khan, M., Rahamathbaba, S., Mateen, M., Ravi Shankar, D., Manzoor Hussain, M. (2019). Effect of NaOH treatment on mechanical strength of banana/epoxy laminates. Polymers from Renewable Resources, 10 (1-3), 19–26. https://doi.org/10.1177/2041247919863626

- Peng, X., Zhong, L., Ren, J., Sun, R. (2010). Laccase and alkali treatments of cellulose fibre: Surface lignin and its influences on fibre surface properties and interfacial behaviour of sisal fibre/phenolic resin composites. Composites Part A: Applied Science and Manufacturing, 41 (12), 1848–1856. https://doi.org/10.1016/j.compositesa.2010.09.004

- Gundara, G., Nurzein, A. S., Wagiman, A., Ramadhan, A. R. (2023). Effect of Alkalized Pineapple Leaf Fiber Direction Variations on Tensile Strength and Bending of Polyester Matrix Composites. Formosa Journal of Sustainable Research, 2 (1), 87–96. https://doi.org/10.55927/fjsr.v2i1.2703

- Aravindh, M., Sathish, S., Ranga Raj, R., Karthick, A., Mohanavel, V., Patil, P. P. et al. (2022). A Review on the Effect of Various Chemical Treatments on the Mechanical Properties of Renewable Fiber-Reinforced Composites. Advances in Materials Science and Engineering, 2022, 1–24. https://doi.org/10.1155/2022/2009691

- Annamalai, K., Soundararajan, S., Kalidas, S., Marialueedass, N. (2024). Explorations into the mechanical properties of composites reinforced with sisal and abaca natural fibers. Matéria (Rio Janeiro). https://doi.org/10.1590/1517-7076-rmat-2024-0585

- Kabir, M. M., Alhaik, M. Y., Aldajah, S. H., Lau, K. T., Wang, H., Islam, M. M. (2021). Effect of Hemp Fibre Surface Treatment on the Fibre‐Matrix Interface and the Influence of Cellulose, Hemicellulose, and Lignin Contents on Composite Strength Properties. Advances in Materials Science and Engineering, 2021 (1). https://doi.org/10.1155/2021/9753779

- Setswalo, K., Molaletsa, N., Oladijo, O. P., Akinlabi, E. T., Sanjay, M. R., Siengchin, S. (2021). The Influence of Fiber Processing and Alkaline Treatment on the Properties of Natural Fiber-reinforced Composites: A Review. Applied Science and Engineering Progress. https://doi.org/10.14416/j.asep.2021.08.005

- Torres, G. B., Hiranobe, C. T., da Silva, E. A., Cardim, G. P., Cardim, H. P., Cabrera, F. C. et al. (2023). Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry. Polymers, 15 (20), 4183. https://doi.org/10.3390/polym15204183

- Osman, Z., Elamin, M., Ghorbel, E., Charrier, B. (2025). Influence of Alkaline Treatment and Fiber Morphology on the Mechanical, Physical, and Thermal Properties of Polypropylene and Polylactic Acid Biocomposites Reinforced with Kenaf, Bagasse, Hemp Fibers and Softwood. Polymers, 17 (7), 844. https://doi.org/10.3390/polym17070844

- Atmakuri, A., Palevicius, A., Janusas, G., Eimontas, J. (2022). Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties. Polymers, 14 (21), 4530. https://doi.org/10.3390/polym14214530

- Hestiawan, H., Zuliantoni, Supardi, N. I., Sudibyo (2025). Characteristics of Lantung Fiber and the Effect of Alkali Treatment and Water Absorption on the Mechanical Properties of Lantung Fiber Reinforced Composites. Jordan Journal of Mechanical and Industrial Engineering, 19 (02), 469–478. https://doi.org/10.59038/jjmie/190217

- Abraha, K. G., Debeli, D. K., Ghani, M. U., Tesfahunegn, A. A., Guo, J. (2023). Enset Fiber-Reinforced Polylactic Acid-Based Biocomposites for High-Performance Application. Journal of Composites Science, 7 (10), 407. https://doi.org/10.3390/jcs7100407

- Fadhillah, A. R., Hermawan, D., Wardhani, A. R. (2020). Pengaruh prosentase larutan NaOH pada proses alkalisasi serat kulit pohon waru (hibiscus tiliaceus) sebagai reinforcement komposit terhadap kekuatan tarik serat tunggal. Turbo : Jurnal Program Studi Teknik Mesin, 8 (2). https://doi.org/10.24127/trb.v8i2.1159

- Karthikeyan, A., Balamurugan, K., Kalpana, A. (2014). The effect of sodium hydroxide treatment and fiber length on the tensile property of coir fiber-reinforced epoxy composites. Science and Engineering of Composite Materials, 21 (3). https://doi.org/10.1515/secm-2013-0130

- ASTM D3039/D3039M-17. Test Method for Tensile Properties of Polymer Matrix Composite Materials. https://doi.org/10.1520/d3039_d3039m-17

- Saba, N., Paridah, M. T., Abdan, K., Ibrahim, N. A. (2016). Effect of oil palm nano filler on mechanical and morphological properties of kenaf reinforced epoxy composites. Construction and Building Materials, 123, 15–26. https://doi.org/10.1016/j.conbuildmat.2016.06.131

- Malalli, C. S., Ramji, B. R. (2022). Mechanical characterization of natural fiber reinforced polymer composites and their application in Prosthesis: A review. Materials Today: Proceedings, 62, 3435–3443. https://doi.org/10.1016/j.matpr.2022.04.276

- Firda, M. (2025). Image of The Morphology Test Results of Lantung Bark (Artocarpus Elasticus). Research Center for Biomass and Bioproduct, National Research and Innovation Agency. Available at: https://drive.google.com/file/d/199r4myKg5-j3zEMVN9jDEx1m71-P1_t1/view?usp=drive_link

- Firda, M. (2025). Tensile Test Results of Artocarpus Elasticus Fibers Treated with Sodium Hydroxide (NaOH). Research Center for Biomass and Bioproduct, National Research and Innovation Agency. Available at: https://drive.google.com/file/d/1PWZMPA8r4U8qj6fsFwvehHM0RYkz3S6y/view?usp=drive_link

- Firda, M. (2025). Bending Test Results of Artocarpus Elasticus Fibers Treated with Sodium Hydroxide (NaOH). Research Center for Biomass and Bioproduct, National Research and Innovation Agency. Available at: https://drive.google.com/file/d/1AmL4tgckzHtOttyHhqFuQXhGf9abBNly/view?usp=drive_link

- Fitri, M., Mahzan, S., Anggara, F. (2021). The Mechanical Properties Requirement for Polymer Composite Automotive Parts - A Review. International Journal of Advanced Technology in Mechanical, Mechatronics and Materials, 1 (3), 125–133. https://doi.org/10.37869/ijatec.v1i3.38

- Kumar, R. S., Muralidharan, N., Sathyamurthy, R. (2020). Optimization of Alkali Treatment Process Parameters for Kenaf Fiber: Experiments Design. Journal of Natural Fibers, 19 (11), 4276–4285. https://doi.org/10.1080/15440478.2020.1856276

- Simamora, P., Simanjuntak, J., Sinulingga, K., Laksono, A. D. (2023). Mechanical Properties of Polypropylene Composites with different Reinforced Natural Fibers – A Comparative Study. Journal of Ecological Engineering, 24 (7), 311–317. https://doi.org/10.12911/22998993/164757

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tri Mulyanto, Firda Aulya Syamani, Ismadi Ismadi, Deni Purnomo, Mona Nurjanah, Iman Setyadi, Abdul Azis Abdillah, Sulaksana Permana

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.