Substantiating the YOLO11 architecture for determining the fractional composition of winter wheat grain mixtures

DOI:

https://doi.org/10.15587/1729-4061.2025.338124Keywords:

machine vision, image segmentation, YOLO, grain mixtures, winter wheat, fractional compositionAbstract

This study’s object is the process of determining the fractional composition of winter wheat grain mixtures using computer vision and deep learning methods. The basic task that needs to be solved is the high complexity, subjectivity, and speed of determining the fractional composition of grain by conventional methods.

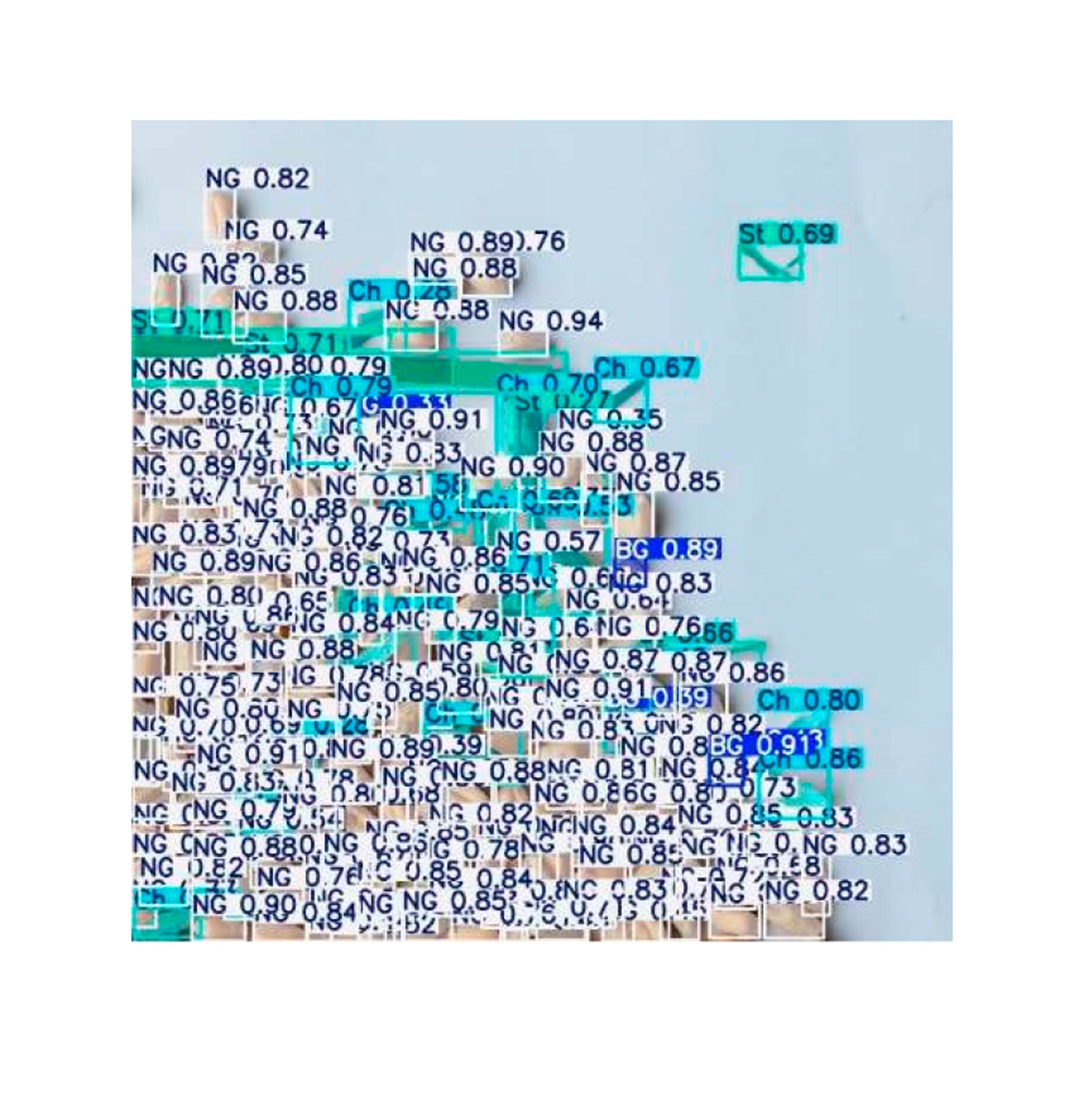

The results obtained demonstrate the successful training and comparative analysis of several YOLO11-seg instance segmentation models on a specialized dataset deployed on the NVIDIA Jetson Orin platform. In particular, the YOLO11m-seg model with an image size of 640 × 640 pixels achieved the optimal compromise between accuracy and speed, achieving a Mask mAP50-95 index of 0.558 at an output speed of 62.5 ms/image. Training the YOLO11n-seg 1280 × 1280 model provided the best average segmentation accuracy (Mask mAP50-95 0.640) by increasing the performance of identifying objects of "complex" classes, which are key for accurate determination of the fractional composition.

The results have made it possible to solve the problem under consideration through the empirically justified choice of architecture. Unlike hypothetical approaches, the study provides specific quantitative data on the performance of different YOLO11-seg architectures. That allowed for a reasonable selection of the model that best meets the requirements for accuracy and speed for practical deployment, solving the problem of uncertainty in the choice of architecture.

The findings create the basis for automating grain quality control, increasing its efficiency, objectivity, and also significantly reducing labor intensity by automating routine operations. For practical use of the system, it is necessary to ensure stable lighting conditions, as well as the presence of a digital camera, a computer, and appropriate software

References

- Walker, C. K., Assadzadeh, S., Wallace, A. J., Delahunty, A. J., Clancy, A. B., McDonald, L. S. et al. (2023). Technologies and Data Analytics to Manage Grain Quality On-Farm—A Review. Agronomy, 13 (4), 1129. https://doi.org/10.3390/agronomy13041129

- Barbedo, J. G. A. (2025). A Review of Artificial Intelligence Techniques for Wheat Crop Monitoring and Management. Agronomy, 15 (5), 1157. https://doi.org/10.3390/agronomy15051157

- Looh, G. A., Xie, F., Wang, X., Looh, A. N., Hind, H. (2025). Grain kernel damage during threshing: a comprehensive review of theories and models. Journal of Agricultural Engineering. https://doi.org/10.4081/jae.2025.1674

- Stepanenko, S., Kotov, B., Kuzmych, A., Kalinichenko, R., Hryshchenko, V. (2023). Research of the process of air separation of grain material in a vertical zigzag channel. Journal of Central European Agriculture, 24 (1), 225–235. https://doi.org/10.5513/jcea01/24.1.3732

- Zhao, W., Liu, S., Li, X., Han, X., Yang, H. (2022). Fast and accurate wheat grain quality detection based on improved YOLOv5. Computers and Electronics in Agriculture, 202, 107426. https://doi.org/10.1016/j.compag.2022.107426

- Saini, M., Singh, J., Prakash, N. R. (2014). Analysis of Wheat Grain Varieties Using Image Processing: A Review. International Journal of Science and Research (IJSR), 3 (6), 490–495. Available at: https://www.ijsr.net/getabstract.php?paperid=2014254

- Rong, D., Wang, H., Xie, L., Ying, Y., Zhang, Y. (2020). Impurity detection of juglans using deep learning and machine vision. Computers and Electronics in Agriculture, 178, 105764. https://doi.org/10.1016/j.compag.2020.105764

- Gupta, P. K., Waoo, A. A. (2024). Analyzing machine learning methods to enhance grain quality assessment and evolution. ShodhKosh: Journal of Visual and Performing Arts, 5 (1). https://doi.org/10.29121/shodhkosh.v5.i1.2024.1876

- Sirohi, A., Malik, A. (2021). A Hybrid Model for the Classification of Sunflower Diseases Using Deep Learning. 2021 2nd International Conference on Intelligent Engineering and Management (ICIEM), 58–62. https://doi.org/10.1109/iciem51511.2021.9445342

- Ünal, Y., Dudak, M. N. (2024). Deep Learning Approaches for Sunflower Disease Classification: A Study of Convolutional Neural Networks with Squeeze and Excitation Attention Blocks. Bitlis Eren Üniversitesi Fen Bilimleri Dergisi, 13 (1), 247–258. https://doi.org/10.17798/bitlisfen.1380995

- Hu, K., Coleman, G., Zeng, S., Wang, Z., Walsh, M. (2020). Graph weeds net: A graph-based deep learning method for weed recognition. Computers and Electronics in Agriculture, 174, 105520. https://doi.org/10.1016/j.compag.2020.105520

- Kaldarova, M., Аkanova, A., Nazyrova, A., Mukanova, A., Tynykulova, A. (2023). Identification of weeds in fields based on computer vision technology. Eastern-European Journal of Enterprise Technologies, 4 (2 (124)), 44–52. https://doi.org/10.15587/1729-4061.2023.284600

- Qiu, Z., Wang, F., Wang, W., Li, T., Jin, X., Qing, S., Shi, Y. (2024). YOLO-SDL: a lightweight wheat grain detection technology based on an improved YOLOv8n model. Frontiers in Plant Science, 15. https://doi.org/10.3389/fpls.2024.1495222

- Dang, F., Chen, D., Lu, Y., Li, Z. (2023). YOLOWeeds: A novel benchmark of YOLO object detectors for multi-class weed detection in cotton production systems. Computers and Electronics in Agriculture, 205, 107655. https://doi.org/10.1016/j.compag.2023.107655

- Sharma, D., Sawant, S. D. (2017). Grain quality detection by using image processing for public distribution. 2017 International Conference on Intelligent Computing and Control Systems (ICICCS), 1118–1122. https://doi.org/10.1109/iccons.2017.8250640

- Kaya, E., Saritas, İ. (2019). Towards a real-time sorting system: Identification of vitreous durum wheat kernels using ANN based on their morphological, colour, wavelet and gaborlet features. Computers and Electronics in Agriculture, 166, 105016. https://doi.org/10.1016/j.compag.2019.105016

- Kong, Q., Ma, N. (2025). Wheat grain appearance quality detection based on improved YOLOv8n. INMATEH Agricultural Engineering, 356–365. https://doi.org/10.35633/inmateh-75-30

- Shen, Y., Yin, Y., Li, B., Zhao, C., Li, G. (2021). Detection of impurities in wheat using terahertz spectral imaging and convolutional neural networks. Computers and Electronics in Agriculture, 181, 105931. https://doi.org/10.1016/j.compag.2020.105931

- Ma, N., Su, Y., Yang, L., Li, Z., Yan, H. (2024). Wheat Seed Detection and Counting Method Based on Improved YOLOv8 Model. Sensors, 24 (5), 1654. https://doi.org/10.3390/s24051654

- Fan, L., Ding, Y., Fan, D., Di, D., Pagnucco, M., Song, Y. (2022). GrainSpace: A Large-scale Dataset for Fine-grained and Domain-adaptive Recognition of Cereal Grains. 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 21084–21093. https://doi.org/10.1109/cvpr52688.2022.02044

- Zhang, J., Min, A., Steffenson, B. J., Su, W.-H., Hirsch, C. D., Anderson, J. et al. (2022). Wheat-Net: An Automatic Dense Wheat Spike Segmentation Method Based on an Optimized Hybrid Task Cascade Model. Frontiers in Plant Science, 13. https://doi.org/10.3389/fpls.2022.834938

- Guo, X., Wang, J., Gao, G., Cheng, Z., Qiao, Z., Zhang, R. et al. (2025). LWheatNet: a lightweight convolutional neural network with mixed attention mechanism for wheat seed classification. Frontiers in Plant Science, 15. https://doi.org/10.3389/fpls.2024.1509656

- Stepanenko, S., Kuzmych, A., Kharchenko, S., Andrey, B., Dnes, V., Volyk, D., Kalinichenko, R. (2025). A Machine Vision Approach for Grain Quality Control During Separation. Journal of Engineering Sciences, 12 (1), E9–E17. https://doi.org/10.21272/jes.2025.12(1).e2

- NVIDIA® Jetson AGX Orin™ 64GB Developer Kit. Stereolabs.

- Segmentation Models. Ultralytics. Available at: https://docs.ultralytics.com/tasks/segment/#models

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Serhii Stepanenko, Alvian Kuzmych, Andrii Borys, Viktor Dnes, Serhii Kharchenko, Ivan Rogovskii, Gennadii Golub, Mykola Berezovyi, Andrii Lutsiuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.