Identifying the energy consumption to material removal rate in abrasive cutting process using the thin grinding wheel

DOI:

https://doi.org/10.15587/1729-4061.2025.338832Keywords:

energy consumption, abrasive cutting, cut-off grinding, energy of cutting, material removal rate, thin grinding wheelAbstract

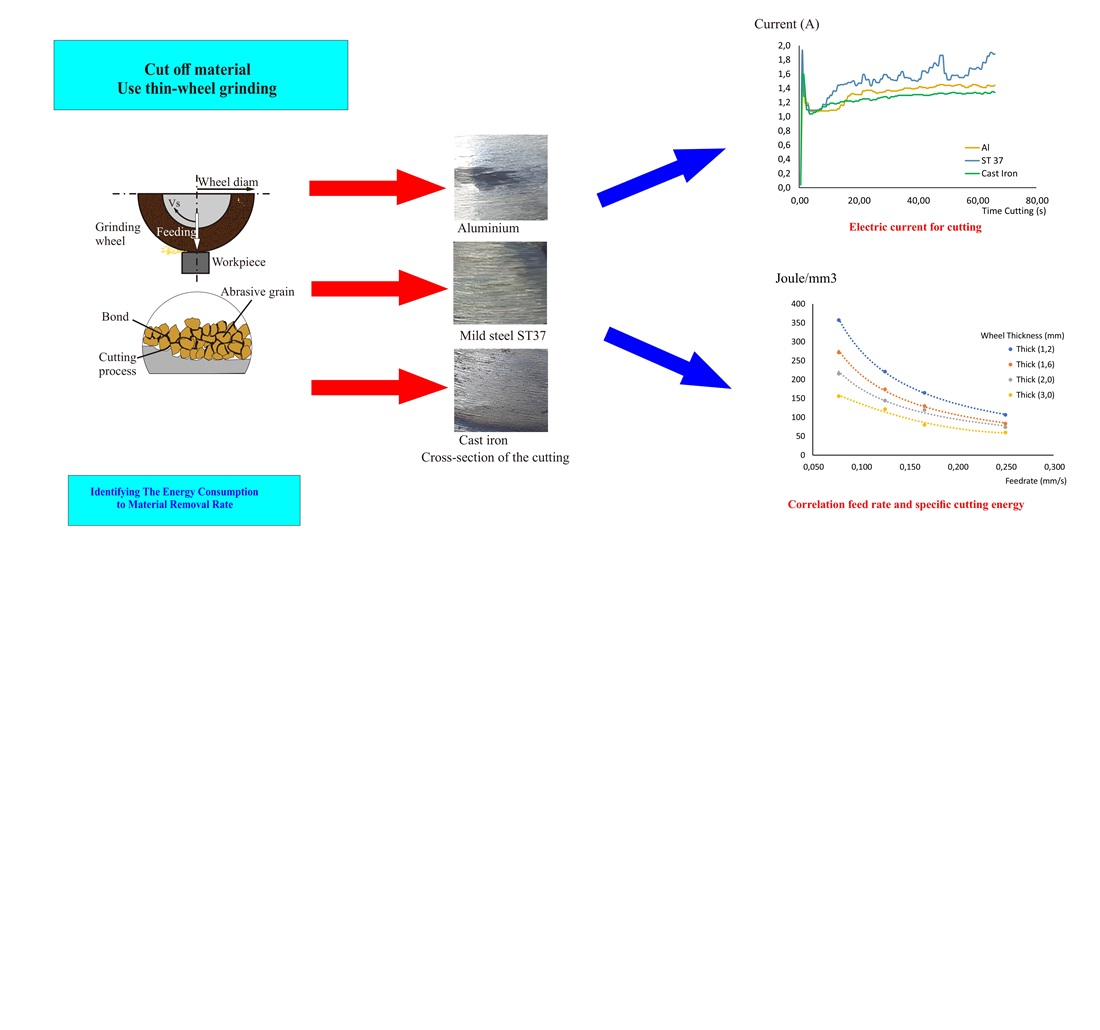

The object of this study is the abrasive cutting process using thin grinding wheels, which is applied for cutting materials with various mechanical properties. The problem to be solved is mapping the energy consumption characteristics in this process through the control of cutting parameters such as grinding wheel thickness and feed rate. An experiment was conducted using grinding wheels with 1.2, 1.6, 2.0, and 3.0 mm for cutting metals. Various feed rates were used to cut Al, ST37, and cast iron, which are ductile, ductile-hard, and brittle materials. The results of the experiment show an inverse exponential relationship between the feed rate and specific energy. The 1.2 mm grinding wheel consumes up to 10% less power than the 3.0 mm wheel at low feed rates. The mapping of these characteristics enables the selection of recommended parameters. Achieving stability during the cutting process of ductile materials, the utilization of a 1.6 mm grinding wheel operating at a feed rate of 0.166 mm/s. The rigidity of the wheel determines the stability of the rotation, which depends on the thickness of the grinding wheel. The thickness of the grinding wheel determines the material removal rate of the abrasive process. Ductile-hard materials, such as ST37, require more energy because the abrasive particles must be able to break down the properties of the material to erode its surface. Ductile materials tend to cause high friction and generate heat, melting the material. The space between the abrasive particles can be filled with liquid material, causing BUE to cover the cutting edge of the abrasive particles. The application of the outcome is aimed at the machining, as a scientific basis for energy control at the manufacturing process

References

- World Energy Outlook 2024. IEA. Available at: https://iea.blob.core.windows.net/assets/140a0470-5b90-4922-a0e9-838b3ac6918c/WorldEnergyOutlook2024.pdf

- Lesinskyi, V., Yemelyanov, O., Zarytska, O., Petrushka, T., Myroshchenko, N. (2022). Designing a toolset for assessing the organizational and technological inertia of energy consumption processes at enterprises. Eastern-European Journal of Enterprise Technologies, 6 (13 (120)), 29–40. https://doi.org/10.15587/1729-4061.2022.267231

- Chen, X., Li, C., Tang, Y., Li, L., Li, H. (2021). Energy efficient cutting parameter optimization. Frontiers of Mechanical Engineering, 16 (2), 221–248. https://doi.org/10.1007/s11465-020-0627-x

- Triebe, M. J., Mendis, G. P., Zhao, F., Sutherland, J. W. (2018). Understanding Energy Consumption in a Machine Tool through Energy Mapping. Procedia CIRP, 69, 259–264. https://doi.org/10.1016/j.procir.2017.11.041

- Saputra, L. D., Yudiyanto, E. (2025). Toolpath Motion Strategy and Feed Rate in CNC Milling on Energy Consumption of Machining Process. Journal of Mechanical Engineering Science and Technology (JMEST), 9 (1), 114. https://doi.org/10.17977/um016v9i12025p114

- He, Y., Liu, F., Wu, T., Zhong, F.-P., Peng, B. (2011). Analysis and estimation of energy consumption for numerical control machining. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 226 (2), 255–266. https://doi.org/10.1177/0954405411417673

- Zare Banadkouki, M. R. (2023). Selection of strategies to improve energy efficiency in industry: A hybrid approach using entropy weight method and fuzzy TOPSIS. Energy, 279, 128070. https://doi.org/10.1016/j.energy.2023.128070

- Hacksteiner, M., Peherstorfer, H., Bleicher, F. (2018). Energy efficiency of state-of-the-art grinding processes. Procedia Manufacturing, 21, 717–724. https://doi.org/10.1016/j.promfg.2018.02.176

- Wang, M., Song, Y., Wang, P., Chen, Y., Sun, T. (2022). Grinding/Cutting Technology and Equipment of Multi-scale Casting Parts. Chinese Journal of Mechanical Engineering, 35 (1). https://doi.org/10.1186/s10033-022-00780-7

- Awan, M. R., Rojas, H. A. G., Benavides, J. I. P., Hameed, S. (2021). Experimental technique to analyze the influence of cutting conditions on specific energy consumption during abrasive metal cutting with thin discs. Advances in Manufacturing, 10 (2), 260–271. https://doi.org/10.1007/s40436-021-00361-2

- Awan, M. R., González Rojas, H. A., Hameed, S., Riaz, F., Hamid, S., Hussain, A. (2022). Machine Learning-Based Prediction of Specific Energy Consumption for Cut-Off Grinding. Sensors, 22 (19), 7152. https://doi.org/10.3390/s22197152

- Rahimifard, S., Seow, Y., Childs, T. (2010). Minimising Embodied Product Energy to support energy efficient manufacturing. CIRP Annals, 59 (1), 25–28. https://doi.org/10.1016/j.cirp.2010.03.048

- Yuan, C., Zhai, Q., Dornfeld, D. (2012). A three dimensional system approach for environmentally sustainable manufacturing. CIRP Annals, 61 (1), 39–42. https://doi.org/10.1016/j.cirp.2012.03.105

- Pawanr, S., Gupta, K. (2024). A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies, 17 (15), 3659. https://doi.org/10.3390/en17153659

- Awan, M. R., González Rojas, H. A., Perat Benavides, J. I., Hameed, S., Hussain, A., Sánchez Egea, A. J. (2022). Specific energy modeling of abrasive cut off operation based on sliding, plowing, and cutting. Journal of Materials Research and Technology, 18, 3302–3310. https://doi.org/10.1016/j.jmrt.2022.03.185

- Kryukov, S. A., Kryukova, A. S. (2017). Determining the Parameters of Grinding Wheels Working Surface Profile. Procedia Engineering, 206, 204–209. https://doi.org/10.1016/j.proeng.2017.10.461

- Wang, Y.-L., Zhang, Y.-B., Cui, X., Liang, X.-L., Li, R.-Z., Wang, R.-X. et al. (2024). High-speed grinding: from mechanism to machine tool. Advances in Manufacturing, 13 (1), 105–154. https://doi.org/10.1007/s40436-024-00508-x

- Gershikov, I. V. (2012). The general approach to the analysis of the temperature grinding. Eastern-European Journal of Enterprise Technologies, 5 (1 (59)), 19–22. Available at: https://journals.uran.ua/eejet/article/view/5865

- Pombo, I., Sánchez, J. A., Martin, E., Godino, L., Álvarez, J. (2024). Accurate Measurement of Temperatures in Industrial Grinding Operations with Steep Gradients. Sensors, 24 (6), 1741. https://doi.org/10.3390/s24061741

- Jedamski, R., Kuhlmann, G., Rößler, M., Karpuschewski, B., Dix, M., Epp, J. (2024). Towards developing a control of grinding processes using a combination of grinding power evaluation and Barkhausen noise analysis. Production Engineering, 18 (2), 339–351. https://doi.org/10.1007/s11740-023-01247-x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Eko Yudiyanto, Satworo Adiwidodo, Sugeng Hadi Susilo, Bayu Pranoto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.