Покращення провідних властивостей шарів друкованої електроніки шляхом обробки коронним розрядом паперових основ перед трафаретним друком

DOI:

https://doi.org/10.15587/1729-4061.2025.339913Ключові слова:

друкована електроніка, гнучка електроніка на папері, графенові провідні шари, зносостійкістьАнотація

Об’єктом дослідження є провідні шари друкованої електроніки на основі графенової пластизольної фарби, нанесені методом трафаретного друку на глянцеві та матові паперові основи, попередньо модифіковані коронним розрядом. Проблема полягала у низькій адгезії та нестабільності провідних шарів на паперових основах, що зумовлено їх шорсткістю, пористістю та гідрофільністю.

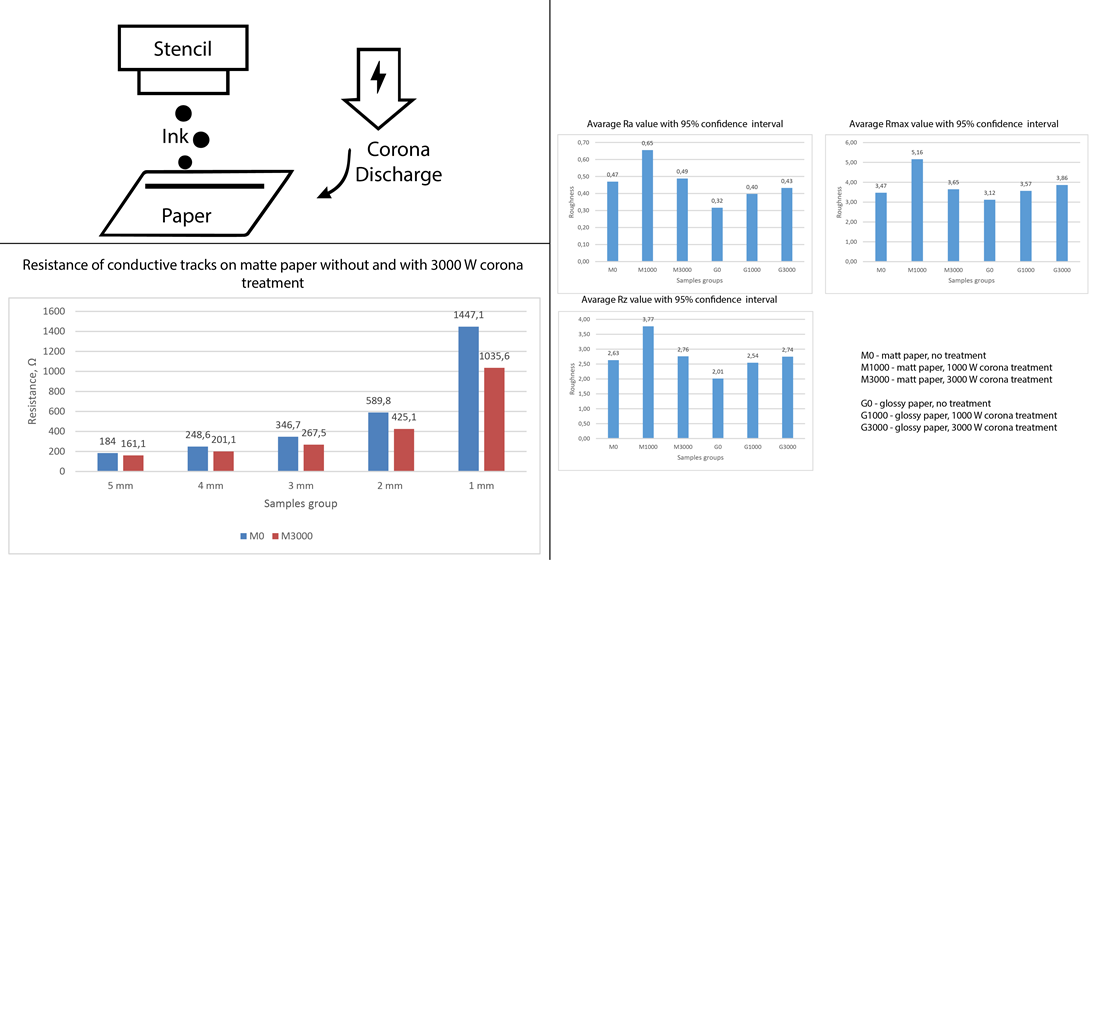

Встановлено, що обробка коронним розрядом знижує питомий опір провідних доріжок на матовому папері до 25–30% у порівнянні з необробленими зразками, а на глянцевому – на 8–12%. Найкращі результати отримано при потужності 3000 Вт: для матового паперу опір доріжок шириною 1 мм зменшився з 1447,1 Ом до 1035,6 Ом, а для 5 мм – з 184,0 Ом до 161,1 Ом. Після випробувань зростання опору у зразків М3000 було в середньому на 2–5%, тоді як у необроблених аналогів – до 46%.

Інтерпретація результатів показала, що підвищення поверхневої енергії та мікрошорсткості після коронної обробки сприяє кращому змочуванню та закріпленню графенової фарби, формуванню щільнішого провідного шару та зменшенню контактних дефектів. Особливістю є підтверджена стабільність електричних характеристик після термоциклів і зменшення частки повних відмов у зразків глянцевого паперу з попередньою обробкою. Додатково відзначено зниження розкиду вимірювань і покращену відтворюваність друку для вузьких доріжок (1–2 мм) на матовому папері після коронування 3000 Вт.

Практичне значення результатів полягає у можливості застосування обробки коронним розрядом у виробництві гнучкої друкованої електроніки на паперових носіях, особливо для мініатюрних елементів із високими вимогами до провідності та зносостійкості. Метод ефективний у умовах масового рулонного (R2R) виробництва, сумісний із тонкими основами і не потребує складної інтеграції в технологічний процес

Посилання

- Khan, Y., Thielens, A., Muin, S., Ting, J., Baumbauer, C., Arias, A. C. (2019). A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Advanced Materials, 32 (15). https://doi.org/10.1002/adma.201905279

- Jansson, E., Lyytikäinen, J., Tanninen, P., Eiroma, K., Leminen, V., Immonen, K., Hakola, L. (2022). Suitability of Paper-Based Substrates for Printed Electronics. Materials, 15 (3), 957. https://doi.org/10.3390/ma15030957

- Cen-Puc, M., Schander, A., Vargas Gleason, M. G., Lang, W. (2021). An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films. Polymers, 13 (12), 1955. https://doi.org/10.3390/polym13121955

- Bouhamed, A., Kia, A. M., Naifar, S., Dzhagan, V., Müller, C., Zahn, D. R. T. et al. (2017). Tuning the adhesion between polyimide substrate and MWCNTs/epoxy nanocomposite by surface treatment. Applied Surface Science, 422, 420–429. https://doi.org/10.1016/j.apsusc.2017.05.177

- Corona Surface Treatment. Available at: https://www.bwconverting.com/brand/brand-category/baldwin/corona-surface-treatment

- Markgraf, D. A. Corona Treatment: An Overview. Enercon Industries. Available at: https://www.enerconind.com/web-treating/wp-content/uploads/sites/3/2023/10/Enercon-corona-treating-overview.pdf

- Khan, S., Lorenzelli, L., Dahiya, R. S. (2015). Technologies for Printing Sensors and Electronics Over Large Flexible Substrates: A Review. IEEE Sensors Journal, 15 (6), 3164–3185. https://doi.org/10.1109/jsen.2014.2375203

- Kyrychok, T., Bardovskyi, B. (2023). Classification of Printing Methods and Printed Electronics Materials. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 4 (82), 22–40. https://doi.org/10.20535/2077-7264.4(82).2023.291596

- Huang, Q., Zhu, Y. (2019). Printing Conductive Nanomaterials for Flexible and Stretchable Electronics: A Review of Materials, Processes, and Applications. Advanced Materials Technologies, 4 (5). https://doi.org/10.1002/admt.201800546

- Kyrychok, T., Bardovskyi, B., Avdiakov, Y., Dusheiko, M. (2024). Effect of Paper Substrate Pretreatment by Corona Discharge on the Conductivity of Metal Electrodes for Printed Electronics Deposited by Magnetron Sputtering. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 3 (85), 110–124. https://doi.org/10.20535/2077-7264.3(85).2024.319104

- Moric, M., Majnaric, I., Barišic, M. (2020). Effect Of Corona Power On The Cmy Reproduction Quality With Electroink Printed On Fine Art Paper. Cellulose Chemistry and Technology, 54 (1-2), 103–111. https://doi.org/10.35812/cellulosechemtechnol.2020.54.12

- Schuman, T. (2023). Corona Discharge Treatment for Surface Modification and Adhesion Improvement. Progress in Adhesion and Adhesives, 203–223. https://doi.org/10.1002/9781394198375.ch5

- Hyun, W. J., Secor, E. B., Hersam, M. C., Frisbie, C. D., Francis, L. F. (2014). High‐Resolution Patterning of Graphene by Screen Printing with a Silicon Stencil for Highly Flexible Printed Electronics. Advanced Materials, 27 (1), 109–115. https://doi.org/10.1002/adma.201404133

- Arapov, K., Rubingh, E., Abbel, R., Laven, J., de With, G., Friedrich, H. (2015). Conductive Screen Printing Inks by Gelation of Graphene Dispersions. Advanced Functional Materials, 26 (4), 586–593. https://doi.org/10.1002/adfm.201504030

- Li, D., Lai, W., Zhang, Y., Huang, W. (2018). Printable Transparent Conductive Films for Flexible Electronics. Advanced Materials, 30 (10). https://doi.org/10.1002/adma.201704738

- Fu, Q., Chen, Y., Sorieul, M. (2020). Wood-Based Flexible Electronics. ACS Nano, 14 (3), 3528–3538. https://doi.org/10.1021/acsnano.9b09817

- Singh, R., Singh, E., Nalwa, H. S. (2017). Inkjet printed nanomaterial based flexible radio frequency identification (RFID) tag sensors for the internet of nano things. RSC Adv., 7 (77), 48597–48630. https://doi.org/10.1039/c7ra07191d

- Tortorich, R., Shamkhalichenar, H., Choi, J.-W. (2018). Inkjet-Printed and Paper-Based Electrochemical Sensors. Applied Sciences, 8 (2), 288. https://doi.org/10.3390/app8020288

- UGENT Conductive Silkscreen Ink UGDC033SSCDSV – High Conductivity Ink for ABS, PC, PET & More – 1kg Pack. Available at: https://www.ugenttech.com/products/ugent-conductive-silkscreen-ink-ugdc033sscdsv-high-conductivity-ink-for-abs-pc-pet-more-1kg-pack

- ToupView: Camera control, imaging software for microscope cameras. ToupTek Photonics. Available at: https://www.touptekphotonics.com/

- MarSurf PS 10. Art. no. 6910230. Available at: https://metrology.mahr.com/en-int/products/article/6910230-mobiles-rauheitsmessgeraet-marsurf-ps-10/

- Mykroskop Sigeta Biogenic Lite 40x-1000x LED Bino. Available at: https://profoptica.com.ua/mikroskop-sigeta-biogenic-lite-40x-1000x-led-bino/

- Multymetr tsyfrovyi Dnipro-M SM600. DNIPRO-M. Available at: https://dnipro-m.ua/tovar/multimetr-czifrovoj-sm600/?campaignid=17724767207&%3Badgroupid=&%3Btargetid=&%3Badid=&%3Bnetwork=x&%3Bkeyword=&%3Bgad_source=1&%3Bgclid=CjwKCAjwmaO4BhAhEiwA5p4YLyJuyl8rAyp9ARB0l0RRy0yDs6D8qoQ7cz0SPiLsmP3KFEL4_5VBPxoCbZgQAvD_BwE

- MC71 Mini Subzero (64 L) climatic heatandcold chamber: –80 °C to +100 °C, ±0.5 °C stability. Available at: https://www.espec.co.jp/products/qa/qa09/03cfc.html/

- Kyrychok, T., Shevchuk, A., Nesterenko, V., Kyrychok, P. (2013). Banknote Paper Deterioration Factors: Circulation Simulator Method. BioResources, 9 (1). https://doi.org/10.15376/biores.9.1.710-724

- Kyrychok, T. Yu. (2014). An Analysis of the Precision of Indicators of the General Deterioration of Banknotes. Measurement Techniques, 57 (2), 166–171. https://doi.org/10.1007/s11018-014-0424-1

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Tetiana Kyrychok, Tetiana Klymenko, Bohdan Bardovskyi, Yevhen Avdiakov

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.