Розроблення екструзійних зернових слайсів із фітоконцентратами

DOI:

https://doi.org/10.15587/1729-4061.2025.340390Ключові слова:

зернові слайси, фітоконцентрати, текстурні властивості, біофлавоноїди, PLS-регресія, функціональні продуктиАнотація

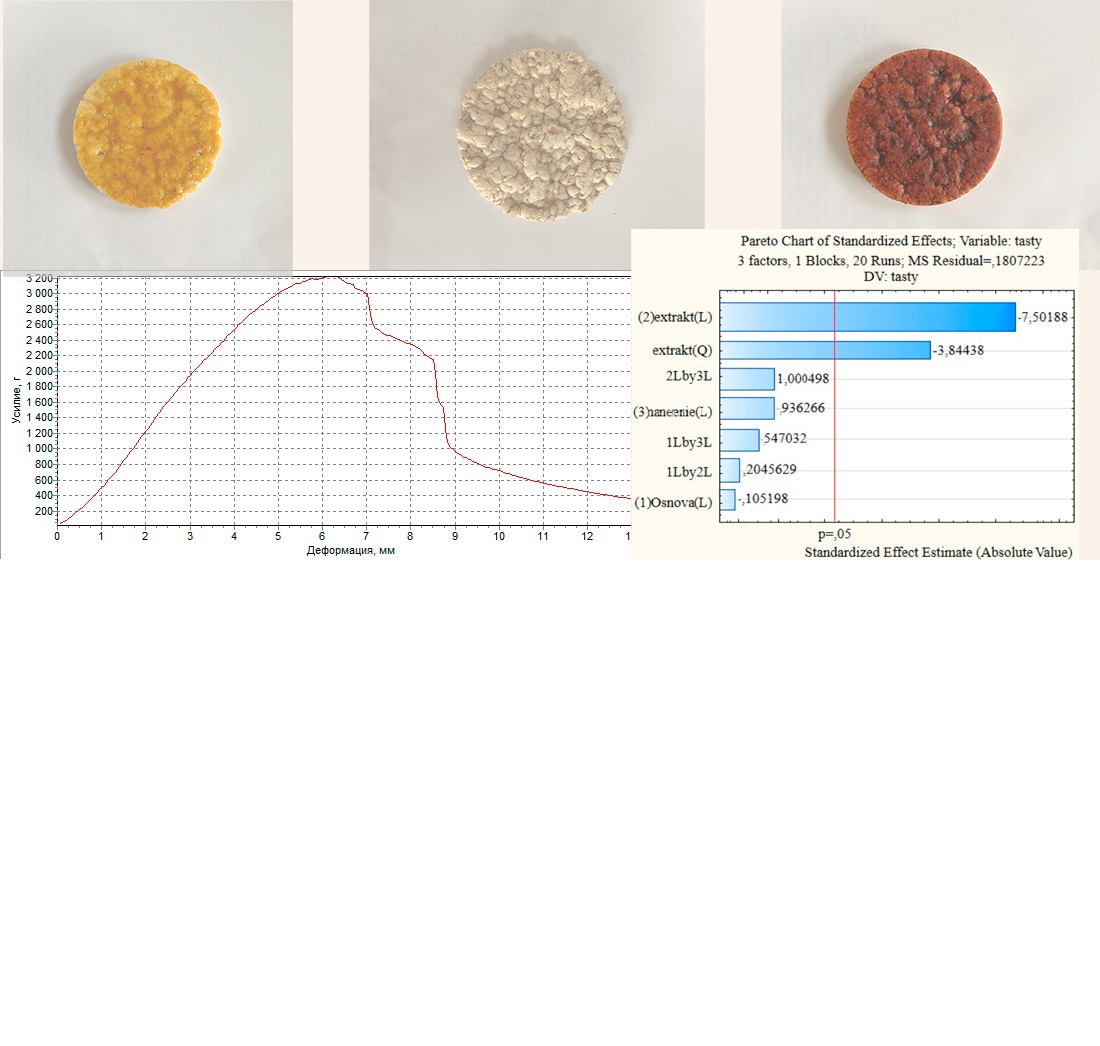

Об’єктом дослідження є екструзійні зернові слайси з додаванням фітоконцентратів дикорослих рослин (обліпихи та глоду). У межах роботи розв’язувалася проблема забезпечення стабільної хрусткої структури за збереження поживної цінності та безпечності. Проведено комплексну фізико-хімічну та механічну оцінку дев’яти рецептур, що включали гречку, пшеницю, кукурудзу, просо й рис, а також фруктові компоненти. Визначено значення вологості (7,8–8,5%), кислотності (2,5–2,9°Т) та зольності (1,2–1,9%). Інструментальна текстурометрія показала, що найбільшу жорсткість (до 460 г/мм) та зусилля руйнування (до 3922 г) демонструють слайси з кукурудзи та пшениці, тоді як гречані зразки мали найбільшу деформацію (до 9,3 мм), що свідчить про м’якішу, менш крихку структуру.

Для кількісної оцінки внеску складу в текстурні властивості побудовано регресійну модель методом часткових найменших квадратів (PLS): коефіцієнт детермінації R² = 0,69, Adj. R² = 0,64, p = 0,0056. Ключовими змінними моделі виступили тип слайсу (VIP = 0,913) і зусилля руйнування (VIP = 0,777). Метод головних компонент (PCA) підтвердив, що компоненти на основі кукурудзи та пшениці корелюють із хрусткістю, тоді як гречка й глід діють як пом’якшувальні агенти. Фруктові добавки помірно підсилювали крихкість за рахунок карамелізації та зміни кислотності.

Стабільність процесу підтверджено контрольними картами X та Moving R. Отримані результати пояснюються низькою залишковою вологістю (< 9%), пористою структурою та збалансованим складом. Запропонований інструментальний підхід дає змогу прогнозувати текстуру нових рецептур і може бути використаний під час розроблення функціональних снеків і хлібозамінників у дієтичному харчуванні

Посилання

- Bresciani, A. (2022). Interplay between raw material and processing conditions for the formulation of pulse-based products. Magazzini digitali. Available at: https://tesidottorato.depositolegale.it/handle/20.500.14242/173646

- Xu, Y., Jia, F., Wu, Y., Jiang, J., Zheng, T., Zheng, H., Yang, Y. (2025). The Impact of Extrusion Cooking on the Physical Properties, Functional Components, and Pharmacological Activities of Natural Medicinal and Edible Plants: A Review. Foods, 14 (11), 1869. https://doi.org/10.3390/foods14111869

- Olakanmi, S. J., Jayas, D. S., Paliwal, J. (2022). Implications of Blending Pulse and Wheat Flours on Rheology and Quality Characteristics of Baked Goods: A Review. Foods, 11 (20), 3287. https://doi.org/10.3390/foods11203287

- Joardder, M. U. H., Rashid, F., Karim, M. A. (2022). The Relationships Between Structural Properties and Mechanical Properties of Plant-Based Food Materials: A Critical Review. Food Reviews International, 39 (9), 6272–6295. https://doi.org/10.1080/87559129.2022.2100415

- van der Sman, R. G. M., van der Goot, A. J. (2023). Hypotheses concerning structuring of extruded meat analogs. Current Research in Food Science, 6, 100510. https://doi.org/10.1016/j.crfs.2023.100510

- Ranjan Purohit, S., Sharma, V., Kumari, M., Muthukumarappan, K., Kane-Potaka, J. (2024). Future Crops and Processing Technologies for Sustainability and Nutritional Security. CRC Press. https://doi.org/10.1201/9781003280170

- Menon, S. C., Dhaliwal, H. K., Du, L., Zhang, S., Wolodko, J., Chen, L., Roopesh, M. S. (2024). Improvement in 3D printability, rheological and mechanical properties of pea protein gels prepared by plasma activated microbubble water. Food Bioscience, 59, 104050. https://doi.org/10.1016/j.fbio.2024.104050

- SDG 1: No poverty. World Health Organization. Available at: https://www.who.int/ru/tools/your-life-your-health/a-healthy-world/prosperity/SDG-1-No-Poverty

- Mishra, G., Sahni, P., Pandiselvam, R., Panda, B. K., Bhati, D., Mahanti, N. K. et al. (2023). Emerging nondestructive techniques to quantify the textural properties of food: A state‐of‐art review. Journal of Texture Studies, 54 (2), 173–205. https://doi.org/10.1111/jtxs.12741

- Sarkar, T., Salauddin, M., Kirtonia, K., Pati, S., Rebezov, M., Khayrullin, M. et al. (2022). A Review on the Commonly Used Methods for Analysis of Physical Properties of Food Materials. Applied Sciences, 12 (4), 2004. https://doi.org/10.3390/app12042004

- Chua, C. K., Yeong, W. Y., Tan, H. W., Zhang, Y., Tan, U.-X., Leo, C. H. et al. (2022). Digital Gastronomy. WORLD SCIENTIFIC. https://doi.org/10.1142/12824

- Blutinger, J. D. (2022). Digital Cuisine: Food Printing and Laser Cooking. Columbia University. https://doi.org/10.7916/G0A3-JF27

- Vilgis, T. A. (2023). Physical Chemistry of Nutrition and Dietary Forms. Nutrition Biophysics, 273–384. https://doi.org/10.1007/978-3-662-67597-7_5

- Dhull, S. B., Bains, A., Chawla, P., Kaur, S. (2024). Pseudocereals. CRC Press. https://doi.org/10.1201/9781003325277

- Kontogiorgos, V. (2023). Hydrocolloids as Texture Modifiers. Food Texturology: Measurement and Perception of Food Textural Properties, 421–435. https://doi.org/10.1007/978-3-031-41900-3_20

- Chen, Y., Chen, L., Xiao, Z., Gao, L. (2022). Effects of enzymolysis and fermentation on the antioxidant activity and functional components of a coarse cereal compound powder based on principal component analysis and microstructure study. Journal of Food Science, 87 (8), 3573–3587. https://doi.org/10.1111/1750-3841.16217

- Wójtowicz, A., Kolasa, A., Mościcki, L. (2013). Influence of Buckwheat Addition on Physical Properties, Texture and Sensory Characteristics of Extruded Corn Snacks. Polish Journal of Food and Nutrition Sciences, 63 (4), 239–244. https://doi.org/10.2478/v10222-012-0076-2

- van der Sman, R. G. M., Vollebregt, H. M., Meinders, M. B. J., Beri, A. (2018). Effects of filler ingredients on the structure and texture of starchy, extruded snacks. Food Structure, 18, 1–13. https://doi.org/10.1016/j.foostr.2018.10.001

- Lazou, A., Krokida, M. (2010). Structural and textural characterization of corn–lentil extruded snacks. Journal of Food Engineering, 100 (3), 392–408. https://doi.org/10.1016/j.jfoodeng.2010.04.024

- Azzollini, D., Derossi, A., Fogliano, V., Lakemond, C. M. M., Severini, C. (2018). Effects of formulation and process conditions on microstructure, texture and digestibility of extruded insect-riched snacks. Innovative Food Science & Emerging Technologies, 45, 344–353. https://doi.org/10.1016/j.ifset.2017.11.017

- Lewko, P., Wójtowicz, A., Kamiński, D. M. (2024). The Influence of Processing Using Conventional and Hybrid Methods on the Composition, Polysaccharide Profiles and Selected Properties of Wheat Flour Enriched with Baking Enzymes. Foods, 13 (18), 2957. https://doi.org/10.3390/foods13182957

- Sharanagat, V. S., Singh, L., Nema, P. K. (2022). Approaches for development of functional and low gluten bread from sorghum: A review. Journal of Food Processing and Preservation, 46 (11). https://doi.org/10.1111/jfpp.17089

- Li, J., Huang, Y., Gao, M., Tie, J., Wang, G. (2024). Shrinkage properties of porous materials during drying: a review. Frontiers in Materials, 11. https://doi.org/10.3389/fmats.2024.1330599

- Tlevlessova, D., Syzdykova, L., Abdiyeva, K., Kozhakhiyeva, M., Yessengaziyeva, A., Sabit, R., Bisengalieva, A. (2025). Optimization of melon preservation technology using texture stabilizers and antioxidants. Eastern-European Journal of Enterprise Technologies, 1 (11 (133)), 51–62. https://doi.org/10.15587/1729-4061.2025.323610

- Saleena Taip, F., Tlevlessova, D., Khamitova, B., Azimova, S., Kuzembayeva, G., Kuzembayev, K., Ablayeva, A. (2025). Devising a production technology and assessing the quality of gluten-free energy bars with a gelled layer. Eastern-European Journal of Enterprise Technologies, 3 (11 (135)), 17–26. https://doi.org/10.15587/1729-4061.2025.329265

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Dinara Tlevlessova, Assel Izembayeva, Asemkul Abdreeva, Makpal Baigaiypkyzy, Galiya Iskakova, Togzhan Akhlan, Zilikha Moldakulova, Kasymkhan Koylanov

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.