Підвищення виходу активного хлору з хлормістких концентратів вдосконаленням процесів електродіалізу

DOI:

https://doi.org/10.15587/1729-4061.2025.341353Ключові слова:

зворотній осмос, електродіалізне очищення води, активний хлор, анодна щільність струмуАнотація

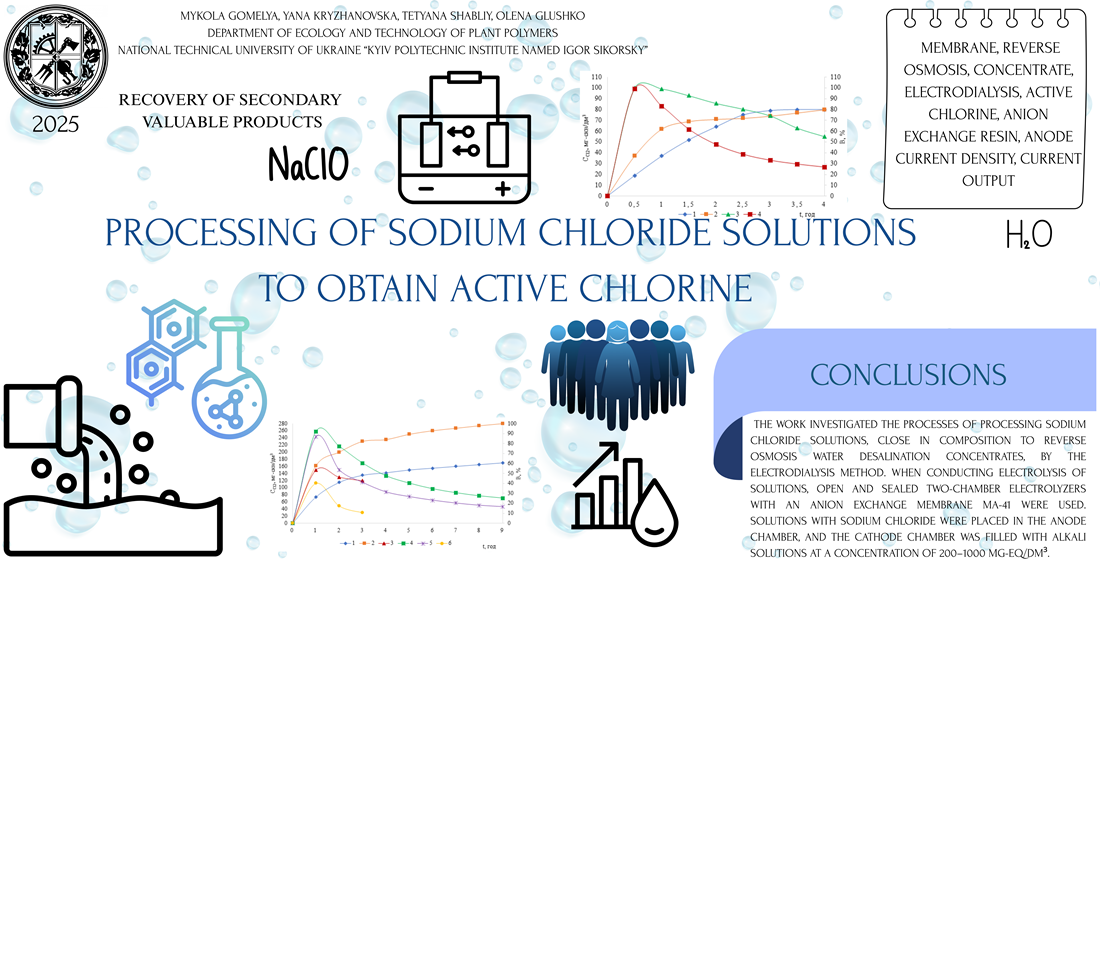

Об’єктом дослідження були процеси переробки розчинів хлоридів натрію концентрацією 3,5–120 г/дм3 методом електродіалізу для вирішення проблеми утилізації хлормістких концентратів мембранного знесолення води з отриманням активного хлору.

При проведенні електролізу розчинів використовували відкриті та герметичні двокамерні електролізери із аніонообмінною мембраною МА-41. Розчини з NaCl розміщували в анодній камері, а катодну камеру наповнювали розчинами NaOH (200–1000 мг-екв/дм3).

Процеси електролізу проводили при анодній щільності струму 1,67–12,5 А/дм2. Із підвищенням анодної щільності струму та концентрації хлоридів у розчині інтенсивність окиснення хлоридів зростає. При анодному окисненні хлоридів разом з утворенням хлору у присутності гідроксидів відбувається утворення гіпохлоритів та хлоридів. Це підтверджує співвідношення кількостей активного хлору та окиснених хлоридів.

Збільшення терміну електролізу у відкритому електролізері не сприяє підвищенню концентрацій окисненого хлору в аноліті через значну його дегазацію. За низьких вихідних концентрацій хлоридів (60 мг-екв/дм3) та при низькій анодній щільності струму (J = 0,83 А/дм2, 1,67 А/дм2) вихід гіпохлориту натрію сягав відповідно 100,0–87,0%. При щільності струму 4,17 А/дм2 за тієї ж концентрації NaCl вихід за струмом гіпохлориту натрію знизився до 51,2%. Концентрація активного хлору у розчинах не перевищувала 80–90 мг-екв/дм3.

При застосуванні герметичного двокамерного електролізера основна маса активного хлору концентрувалась в аноліті. Для уловлювання парів активного хлору гази з анодної зони пропускали крізь розчин NaOH в абсорбері. Концентрації активного хлору в анолітах досягали 1240–1920 мг-екв/дм3. Ступінь дегазації активного хлору не перевищував 11–17%.

Посилання

- WHO Country Office in Ukraine annual report 2024 (2025). Copenhagen: WHO Regional Office for Europe, 116.

- Our Mission (2021). World Economic Forum.

- Trus, I., Gomelya, M., Tverdokhlib, M., Halysh, V., Radovenchyk, I., Benatov, D. (2022). Purification of Mine Waters Using Lime and Aluminum Hydroxochloride. Ecological Engineering & Environmental Technology, 23 (5), 169–176. https://doi.org/10.12912/27197050/152104

- Trus, I. M., Gomelya, M. D. (2021). Desalination of mineralized waters using reagent methods. Journal of Chemistry and Technologies, 29 (3), 417–424. https://doi.org/10.15421/jchemtech.v29i3.214939

- Pro yakist vody, pryznachenoi dlia spozhyvannia liudynoiu (1998). Dyrektyva Rady 98/83/IeS. 03.11.1998. Available at: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=60063

- Nyangi, M. J. (2023). Simultaneous removal of chloride and hardness from groundwater by cassava peel biosorption: Optimization and sorption studies. Remediation Journal, 34 (1). https://doi.org/10.1002/rem.21770

- Tsutano, K. (2022). Application of Monolithic Ion Exchange resins for the field of Ultrapure Water. Journal of Ion Exchange, 33 (3), 51–55. https://doi.org/10.5182/jaie.33.51

- Koliehova, A., Trokhymenko, H., Melnychuk, S., Gomelya, M. (2019). Treatment of Wastewater Containing a Mixture of Heavy Metal Ions (Copper-Zinc, Copper-Nickel) using Ion-Exchange Methods. Journal of Ecological Engineering, 20 (11), 146–151. https://doi.org/10.12911/22998993/112746

- Wang, Y., Yang, S. (2019). Thermodynamic analysis of an absorption-assisted multi-effect thermal desalination system with an extended operating temperature range. Desalination and Water Treatment, 155, 370–380. https://doi.org/10.5004/dwt.2019.23874

- Safder, U., Ifaei, P., Nam, K., Rashidi, J., Yoo, C. (2018). Availability and reliability analysis of integrated reverse osmosis – forward osmosis desalination network. Desalination and Water Treatment, 109, 1–7. https://doi.org/10.5004/dwt.2018.22147

- Vargas, C., Bórquez, R. (2020). Evaluation of the operation seawater and brackish water desalination system using two-pass nanofiltration. Desalination and Water Treatment, 204, 50–58. https://doi.org/10.5004/dwt.2020.26287

- Bagastyo, A. Y., Sari, P. P. I., Direstiyani, L. C. (2020). Effect of chloride ions on the simultaneous electrodialysis and electrochemical oxidation of mature landfill leachate. Environmental Science and Pollution Research, 28 (45), 63646–63660. https://doi.org/10.1007/s11356-020-11519-z

- Zhu, M., He, F., Feng, L., Chi, Y., Li, Y.-Y., Tian, B. (2024). Comparison of bipolar membrane electrodialysis, electrodialysis metathesis, and bipolar membrane electrodialysis multifunction for the conversion of waste Na2SO4: Process performance and economic analysis. Journal of Environmental Management, 370, 122513. https://doi.org/10.1016/j.jenvman.2024.122513

- Gomelya, M., Kryzhanovska, Y., Makarenko, I., Shabliy, T., Kyrylyuk, O. (2025). Evaluation of the efficiency of the processing of sodium chloride solutions by electrodialysis in a three-chamber electrolyzer using a high-basic anionite. Proceedings of the NTUU “Igor Sikorsky KPI”. Series: Chemical Engineering, Ecology and Resource Saving, 2, 60–69. https://doi.org/10.20535/2617-9741.2.2025.333975

- Gomelya, M., Kryzhanovska, Y., Pliatsuk, Y. (2024). Production of active chlorine and sodium hypochlorite in a closed electrolyser. Proceedings of the NTUU “Igor Sikorsky KPI”. Series: Chemical Engineering, Ecology and Resource Saving, 4, 41–50. https://doi.org/10.20535/2617-9741.4.2024.319015

- Liu, Q., Feng, T., Zhu, S., Lu, G. (2024). Simulation study of the electrothermal field in a chloride electrolysis cell with 16 electrode pairs. The Canadian Journal of Chemical Engineering, 102 (11), 3909–3921. https://doi.org/10.1002/cjce.25281

- Gomelya, M., Kryzhanovska, Y. (2023). Concentration of sodium chloride solutions in the processing of concentrates for reverse osmotic water desalification. Proceedings of the NTUU “Igor Sikorsky KPI”. Series: Chemical Engineering, Ecology and Resource Saving, 3, 85–93. https://doi.org/10.20535/2617-9741.3.2023.288253

- Akhter, M., Habib, G., Qamar, S. U. (2018). Application of Electrodialysis in Waste Water Treatment and Impact of Fouling on Process Performance. Journal of Membrane Science & Technology, 8 (2). https://doi.org/10.4172/2155-9589.1000182

- Martins, V. L., Ogden, M. D., Jones, M. R., Trowsdale, S. A., Hall, P. J., Jensen, H. S. (2020). Opportunities for coupled electrochemical and ion-exchange technologies to remove recalcitrant micropollutants in water. Separation and Purification Technology, 239, 116522. https://doi.org/10.1016/j.seppur.2020.116522

- Li, F., Jia, Y., Wang, M. (2024). Recovery of low-concentration waste acid by electrodialysis: Modeling and validation. Journal of Cleaner Production, 482, 144203. https://doi.org/10.1016/j.jclepro.2024.144203

- Gomelya, M., Kryzhanovska, Y., Shabliy, T., Makarenko, I., Hlushko, O., Vember, V. (2025). Synthesis of oxidized chlorine compounds by electrodialysis using a strongly basic anion exchange resin. Ecological Engineering & Environmental Technology, 26 (6), 98–107. https://doi.org/10.12912/27197050/204068

- Scarazzato, T., Panossian, Z., Tenório, J. A. S., Pérez-Herranz, V., Espinosa, D. C. R. (2017). A review of cleaner production in electroplating industries using electrodialysis. Journal of Cleaner Production, 168, 1590–1602. https://doi.org/10.1016/j.jclepro.2017.03.152

- Wang, D., Chen, X., Luo, J., Shi, P., Zhou, Q., Li, A., Pan, Y. (2024). Comparison of chlorine and chlorine dioxide disinfection in drinking water: Evaluation of disinfection byproduct formation under equal disinfection efficiency. Water Research, 260, 121932. https://doi.org/10.1016/j.watres.2024.121932

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Mykola Gomelya, Yana Kryzhanovska, Tetyana Shabliy, Olena Hlushko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.