Formation of a destructive layer in special rubbers depending on CO2-laser processing modes

DOI:

https://doi.org/10.15587/1729-4061.2025.341378Keywords:

rubber, laser engraving, destructive layer depth, CO2 laser power, quality improvementAbstract

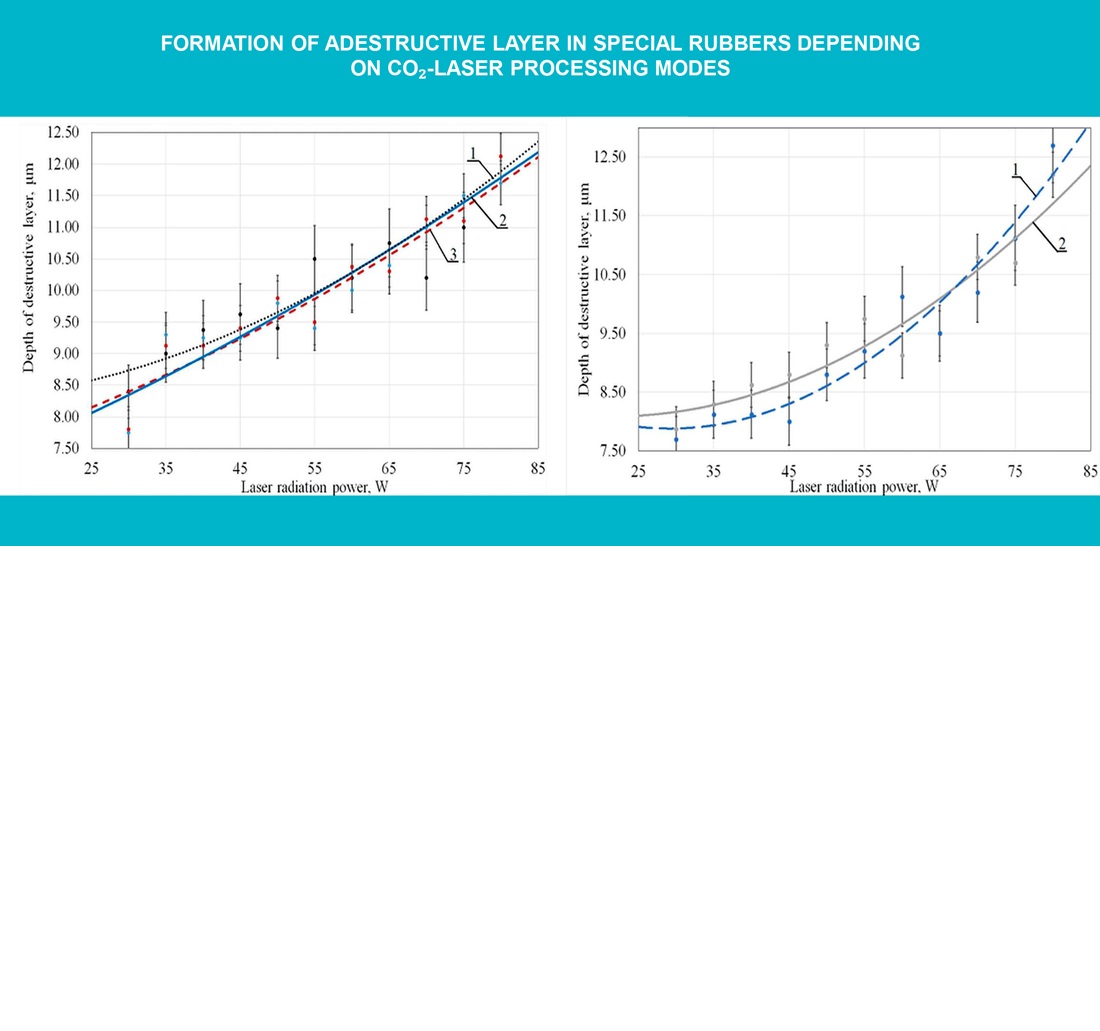

Special rubbers proceeding by laser engraving is the investigation object. Rubber products quality improvement was solving by means of laser engraving, which allows to achieve a high level of details, to get a complex geometry and sustainable quality having a minimum of the tool worn out. Experimental measurements of destructive layer depth inside different samples of rubber in dependence on the modes of CO2-laser processing were conducted. Rubber engraving proceeding by a wavelength of 10.6 μm CO2-laser was considered in the pulse mode series to provide the cutting edge correct geometry keeping fixed conditions of beam movement speed and acceleration.

Concerted experimental results (rubbers AERO Laserrubber, OLIO Laserrubber, TEMPO Laserrubber, CLASSICO Laserrubber and ECO Laserrubber) revealed a sustainable increasing the depth of the destructive layer on average by (1.0 ... 1.2) μm every 5 W along with increasing of CO2-laser power in the range of (30 ... 55) W.

Stabilization or slight fluctuations of the destructive layer depth were stated when power supplied exceeded of 60 W.

Obtained graphs show a high degree coincidence with analytical model and confirm the feasibility of laser engraving appliance exactly within the range of (35 ... 50) W to provide a precise and clean processing of high-quality rubber products

References

- Verhun, O., Oleksiienko, O. (2023). Effect of actual adhesive strength on determination of application conditions for sealing polymer materials. Science and Construction, 35 (1). https://doi.org/10.33644/2313-6679-1-2023-5

- Mitsyk, А. V. (2022). Mathematical simulation of the deformation of the part material surface layer during its finishing and grinding processing with metal balls in the vibration polishing operation. Visnik of the Volodymyr Dahl East Ukrainian National University, 2 (272), 46–51. https://doi.org/10.33216/1998-7927-2022-272-2-46-51

- Dobrotvorskyi, S. S., Khavin, H. L., Basova, Ye. V., Aleksenko, B. O., Prykhodko, V. O. (2024). Shorstkist poverkhni pry lazerniy obrobtsi nerzhaviyuchoi stali. Kharkiv: NTU «KhPI», 167. https://doi.org/10.20998/978-617-05-0513-2

- Mushtaq, R. T., Wang, Y., Rehman, M., Khan, A. M., Mia, M. (2020). State-Of-The-Art and Trends in CO2 Laser Cutting of Polymeric Materials – A Review. Materials, 13 (17), 3839. https://doi.org/10.3390/ma13173839

- Kameyama, N., Yoshida, H., Fukagawa, H., Yamada, K., Fukuda, M. (2021). Thin-Film Processing of Polypropylene and Polystyrene Sheets by a Continuous Wave CO2 Laser with the Cu Cooling Base. Polymers, 13 (9), 1448. https://doi.org/10.3390/polym13091448

- Kameyama, N., Yoshida, H. (2022). Thermal Effect on Thin-Film Formation of the Polymer Sheets by the CO2 Laser with the Copper Base. Polymers, 14 (17), 3508. https://doi.org/10.3390/polym14173508

- Lieber, S. C., Varghese, A. P., Tarantino, R., Tafuni, A. (2023). Additive manufacturing for plastic extrusion die tooling: A numerical investigation. CIRP Journal of Manufacturing Science and Technology, 41, 401–412. https://doi.org/10.1016/j.cirpj.2023.01.003

- Schmidt, B., Rose, M., Zimmermann, M., Kästner, M. (2021). Analysis of process-induced damage in remote laser cut carbon fibre reinforced polymers. Journal of Materials Processing Technology, 295, 117162. https://doi.org/10.1016/j.jmatprotec.2021.117162

- Karamimoghadam, M., Dezaki, M. L., Zolfagharian, A., Bodaghi, M. (2023). Influence of post-processing CO2 laser cutting and FFF 3D printing parameters on the surface morphology of PLAs: Statistical modelling and RSM optimisation. International Journal of Lightweight Materials and Manufacture, 6 (2), 285–295. https://doi.org/10.1016/j.ijlmm.2023.01.004

- Munoz, A., Schmidt, J., Suffet, I. H. M., Tsai, C. S.-J. (2023). Characterization of Emissions from Carbon Dioxide Laser Cutting Acrylic Plastics. ACS Chemical Health & Safety, 30 (4), 182–192. https://doi.org/10.1021/acs.chas.3c00013

- Ham, S. S., Lee, H. (2020). Surface Characteristics of Polymers with Different Absorbance after UV Picosecond Pulsed Laser Processing Using Various Repetition Rates. Polymers, 12 (9), 2018. https://doi.org/10.3390/polym12092018

- Riveiro, A., Maçon, A. L. B., del Val, J., Comesaña, R., Pou, J. (2018). Laser Surface Texturing of Polymers for Biomedical Applications. Frontiers in Physics, 6. https://doi.org/10.3389/fphy.2018.00016

- Ruan, X., Wang, R., Luo, J., Yao, Y., Liu, T. (2018). Experimental and modeling study of CO2 laser writing induced polyimide carbonization process. Materials & Design, 160, 1168–1177. https://doi.org/10.1016/j.matdes.2018.10.050

- Anjum, A., Azharuddin Ali, M., Shaikh, A. A., Akhtar, S. S. (2024). A numerical and experimental analysis of CO2 laser micro-milling on PMMA sheet considering a multipass approach for microfluidic devices. Optics & Laser Technology, 176, 110860. https://doi.org/10.1016/j.optlastec.2024.110860

- Volova, T. G., Golubev, A. I., Nemtsev, I. V., Lukyanenko, A. V., Dudaev, A. E., Shishatskaya, E. I. (2021). Laser Processing of Polymer Films Fabricated from PHAs Differing in Their Monomer Composition. Polymers, 13 (10), 1553. https://doi.org/10.3390/polym13101553

- Ahmad Sobri, S., Chow, T. P., Tatt, T. K., Nordin, M. H., Hermawan, A., Mohamad Amini, M. H. et al. (2025). Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs). Polymers, 17 (16), 2216. https://doi.org/10.3390/polym17162216

- Kashihara, K., Uto, Y., Nakajima, T. (2018). Rapid in situ synthesis of polymer-metal nanocomposite films in several seconds using a CO2 laser. Scientific Reports, 8 (1). https://doi.org/10.1038/s41598-018-33006-9

- Chen, X., Hu, Z. (2018). Study aspect ratio of microchannel on different polymer substrates with CO2 laser and hot bonding for microfluidic chip. AIP Advances, 8 (1). https://doi.org/10.1063/1.5012772

- Ravi-Kumar, S., Lies, B., Lyu, H., Qin, H. (2019). Laser Ablation of Polymers: A Review. Procedia Manufacturing, 34, 316–327. https://doi.org/10.1016/j.promfg.2019.06.155

- LaserBot-900. Available at: https://bot-ua.com/shop/co2/laserbot-900/?v=d41d8cd98f00

- LightBurn. Available at: https://lightburnsoftware.com/

- RUIDA RDWorks Software. Available at: https://www.ruidacontroller.com/ruida-rdworks-software/

- MT Pro Single/Multi-Channel Integrated Interferometer. Available at: https://en.dimension-tech.com/productdetail/6.html

- Classico. Laser rubber for text plate production, 60 Shore-A. Available at: https://www.trodat.net/int/en/shop/product/Products-International/Production-Materials/Laser-Rubber/Classico

- Pukhalska, H. V., Porvin, I. E. (2020). Lazerne markuvannia. TYZhDEN NAUKY-2020. Zaporizhzhia, 21–22. Available at: https://zp.edu.ua/uploads/dept_s&r/2020/conf/4.1/TN_2020-MF.pdf

- Munirathinam, B., Lerch, L., Hüne, D., Lentz, L., Lenk, T., Görke, M. et al. (2022). Enhanced Performance of Laser‐Structured Copper Electrodes Towards Electrocatalytic Hydrogenation of Furfural. ChemElectroChem, 9 (22). https://doi.org/10.1002/celc.202200885

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dmitro Sidorov, Denys Kozik, Iryna Kazak, Tetiana Shylovych, Yurii Pribyliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.