Design of a decision support system for making informed decisions about selection of machines for manufacturing leather garments

DOI:

https://doi.org/10.15587/1729-4061.2025.341457Keywords:

machine selection, database, technological operation, sewing production, decision support systemAbstract

This study investigates the process of selecting sewing machines for the manufacturing of products from artificial leather. Despite the active development of technological solutions for automation, the task of choosing optimal equipment remains relevant, requiring additional tools that can provide a connection between scientific approaches and industrial conditions. This paper reports the results of designing an automated decision support system for the selection of sewing equipment, aimed at bridging the gap between theoretical models and production needs.

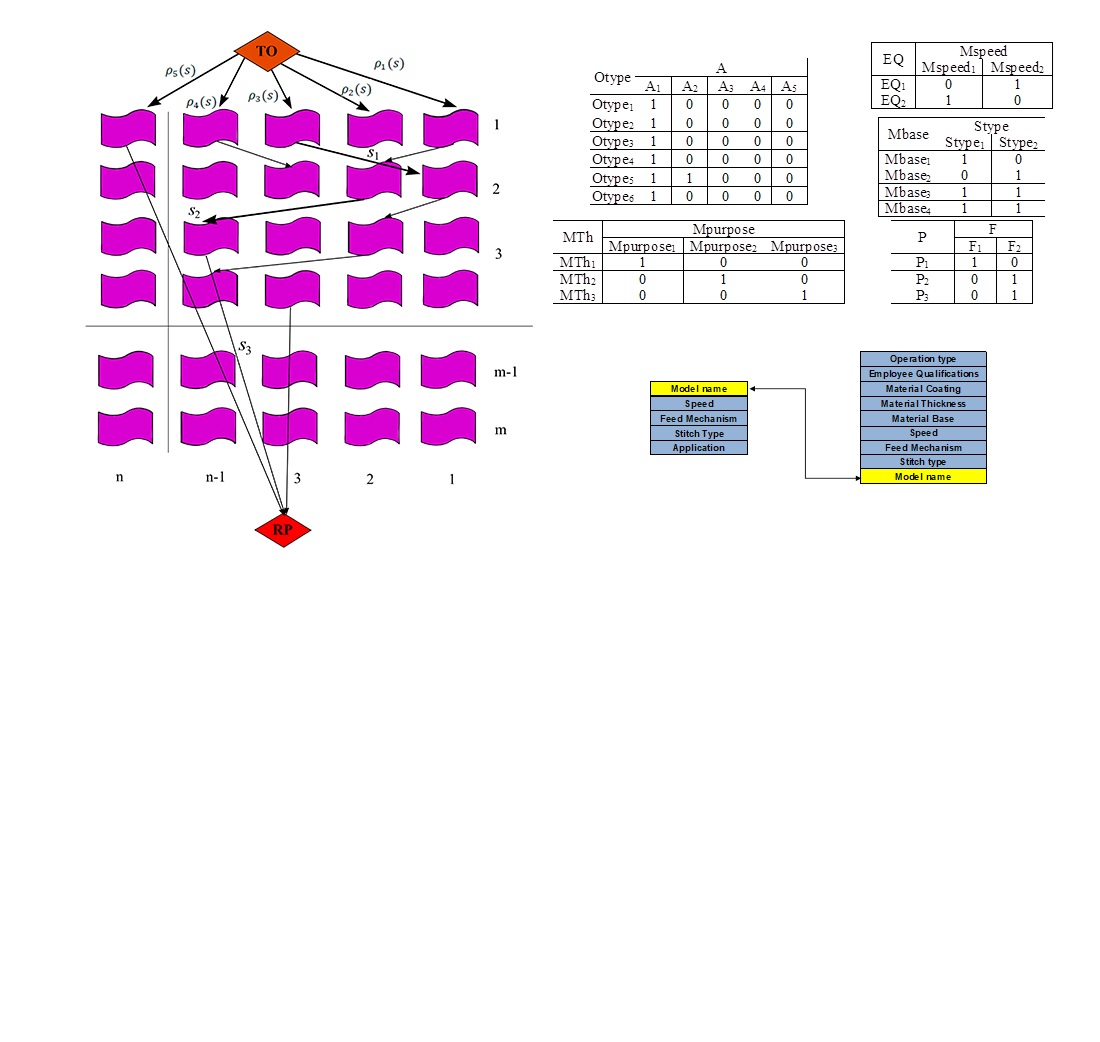

The technological advancement is based on a three-level database structure. At the data storage level, a matrix-based database of equipment parameters was constructed, ensuring the consistency of information regarding technological operations, materials, and machine characteristics. At the logical level, a multifactor analysis algorithm was developed, utilizing the principles of graph theory, a binary matrix, and the linear programming method to select the optimal equipment model. The representation level is an interactive interface based on MS Excel (USA). Input parameters are selected by simply clicking on buttons with corresponding names (seam type, worker qualification, material properties, and thickness). The system automatically analyzes the database and generates a list of recommended equipment in a table format.

Verification was carried out through a survey involving 30 participants (86.7% were representatives of the academic community). The results show that 93.3% of respondents noted the high speed of the simulator while 90.0% rated its practicality and 86.7% its convenience. At the same time, certain shortcomings were identified, outlining areas for further research: 23.3% of those surveyed highlighted the need to expand the database, and 16.7% emphasized the necessity of implementing a Ukrainian-language version.

It was established that the designed system is a universal tool that combines educational and practical-production dimensions. Its implementation in the educational process will contribute to achieving a number of program learning outcomes

References

- Meyer, M., Dietrich, S., Schulz, H., Mondschein, A. (2021). Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives. Coatings, 11 (2), 226. https://doi.org/10.3390/coatings11020226

- Tokuda, F., Murakami, R., Seino, A., Kobayashi, A., Hayashibe, M., Kosuge, K. (2025). Fixture-Free 2D Sewing Using a Dual-Arm Manipulator System. IEEE Transactions on Automation Science and Engineering, 22, 7927–7940. https://doi.org/10.1109/tase.2024.3474914

- Kong, R. W. M. (2025). Innovative Automated Stretch Elastic Waistband Sewing Machine for Garment Manufacturing. International Research Journal of Modernization in Engineering Technology and Science. https://doi.org/10.56726/irjmets70275

- Jindal, H., Kaur, S. (2021). Robotics and Automation in Textile Industry. International Journal of Scientific Research in Science, Engineering and Technology, 8 (3), 40–45. https://doi.org/10.32628/ijsrset21839

- Forlini, M., Ciccarelli, M., Carbonari, L., Papetti, A., Palmieri, G. (2024). Smart automation in luxury leather shoe polishing: a human centric robotic approach. International Journal of Computer Integrated Manufacturing, 38 (9), 1329–1343. https://doi.org/10.1080/0951192x.2024.2421313

- Huan, Y., Ren, G., Sun, J., Jin, G., Ding, X., Du, W. (2024). Efficient leather spreading operations by dual-arm robotic systems. Scientific Reports, 14 (1). https://doi.org/10.1038/s41598-024-66904-2

- Seino, A., Terayama, J., Tokuda, F., Kobayashi, A., Kosuge, K. (2022). Robot End-effector for Fabric Folding. https://doi.org/10.36227/techrxiv.21283725.v1

- Boz, S., Birkocak, D. T., Necef, Ö. K., Kiliç, A., Öndoğan, Z. (2022). Investigation of sewing parameters caused fabric damages. W: AUTEX 2022 : 21st World Textile Conference AUTEX 2022 - AUTEX Conference Proceedings. Lodz, 40–44. https://doi.org/10.34658/9788366741751.9

- Tang, K., Tokuda, F., Seino, A., Kobayashi, A., Tien, N. C., Kosuge, K. (2024). Time-Scaling Modeling and Control of Robotic Sewing System. IEEE/ASME Transactions on Mechatronics, 29 (4), 3166–3174. https://doi.org/10.1109/tmech.2024.3398713

- Martínez-Peral, F. J., Migallón, H., Borrell-Méndez, J., Martínez-Rach, M., Pérez-Vidal, C. (2024). Manipulation order optimization in industrial pick-and-place operations: application to textile and leather industry. The International Journal of Advanced Manufacturing Technology, 133 (1-2), 987–1010. https://doi.org/10.1007/s00170-024-13436-8

- Zakharkevich, O., Zhylenko, T., Koshevko, J., Shvets, G. (2023). Development of an algorithm for the reasoned selection of machines for leather garments manufacturing. Eastern-European Journal of Enterprise Technologies, 5 (3 (125)), 86–94. https://doi.org/10.15587/1729-4061.2023.287482

- Shahriar, M. M., Parvez, M. S., Talapatra, S. (2022). Hierarchizing the Product Characteristics of Industrial Plain Sewing Machine for Making Best Purchase Decision. Mathematical Problems in Engineering, 2022, 1–17. https://doi.org/10.1155/2022/2578875

- Kalwar, M. A., Khan, M. A., Wassan, A. N., Phul, Z., Shaikh, S. A., Marri, H. B. (2023). Automation of Post-Order Costing Analysis By Using Visual Basic For Applications In Microsoft Excel: A Case Study. WPOM-Working Papers on Operations Management, 14 (2), 101–136. https://doi.org/10.4995/wpom.18697

- Swaminathan, V., Saffiudeen, M. F., Gupta, S., Alamri, Y. A. (2024). Review of semiconductor laser diode technologies for sustainable energy in leather machining. Clean Technologies and Environmental Policy, 27 (2), 577–606. https://doi.org/10.1007/s10098-024-02976-y

- Werheid, J., Melnychuk, O., Zhou, H., Huber, M., Rippe, C., Joosten, D. et al. (2024). Designing an LLM-Based Copilot for Manufacturing Equipment Selection. arXiv. https://doi.org/10.48550/arXiv.2412.13774

- Kefale, G. Y., Bizuneh, B., Getachew, L., Karthikeyan, R. (2025). Innovative Pathways in Leather Industry: A Comprehensive Review of Sustainable Technologies and Strategies. Journal of Scientific & Industrial Research, 84 (6). https://doi.org/10.56042/jsir.v84i6.10781

- Kim, M., Ahn, J., Kang, J., Kim, S. (2020). A Systematic Review on Smart Manufacturing in the Garment Industry. Fashion & Textile Research Journal, 22 (5), 660–675. https://doi.org/10.5805/sfti.2020.22.5.660

- Zakharkevich, O., Poluchovich, I., Kuleshova, S., Koshevko, J., Shvets, G., Shvets, A. (2021). “CloStyler” – mobile application to calculate the parameters of clothing blocks. IOP Conference Series: Materials Science and Engineering, 1031 (1), 012031. https://doi.org/10.1088/1757-899x/1031/1/012031

- Zakharkevich, O., Koshevko, J., Shvets, G., Kuleshova, S., Bazyliuk, E., Paraska, O., Kazlacheva, Z. (2022). Development of the Mobile Application to Calculate Parameters of Underwear Patterns. Terotechnology XII, 24, 309–315. https://doi.org/10.21741/9781644902059-45

- Karakiş, E. (2021). Machine Selection for a Textile Company with CRITIC and MAUT Methods. European Journal of Science and Technology. https://doi.org/10.31590/ejosat.994697

- Ulutaş, A. (2020). New Grey Integrated Model to Solve Machine Selection Problem for a Textile Company. Fibres and Textiles in Eastern Europe, 28 (1 (139)), 20–25. https://doi.org/10.5604/01.3001.0013.5853

- Tama Birkocak, D. (2022). Effects of Needle Size and Sewing Thread on Seam Quality of Traditional Fabrics. Tekstil ve Konfeksiyon, 32 (3), 277–287. https://doi.org/10.32710/tekstilvekonfeksiyon.1088043

- Syabani, Muh. W., Devi, C., Hermiyati, I., Angkasa, A. D. (2020). The effect of PVC’s resin K-value on the mechanical properties of the artificial leather. Majalah Kulit, Karet, Dan Plastik, 35 (2), 75. https://doi.org/10.20543/mkkp.v35i2.5639

- Watanabe, S., Tominaga, S., Horiuchi, T. (2020). The Difference in Impression between Genuine and Artificial Leather: Quantifying the Feeling of Authenticity. Journal of Perceptual Imaging, 3 (2), 020501-1-020501–020511. https://doi.org/10.2352/j.percept.imaging.2020.3.2.020501

- Ersöz, T., Tenbeli, R., Ersöz, F. (2021). Visual analysis of turkey's textile sector with Gephi complex network. Proceding of 11th International Symposium on Intelligent Manufacturing and Service System. Sakarya, 519–529. https://doi.org/10.5281/zenodo.16411310

- Angeli. Available at: https://angeli.net.ua/uk/juki

- Amtex. Available at: https://amtex.com.ua/brands/shvejnoe_oborydovanie_juki/

- Lapka.com.ua. Available at: https://www.lapka.com.ua/ua/brand-juki.aspx

- Sewtech. Available at: https://sewtech.com.ua/uk/promislovi-shvejni-mashini/brand-juki/

- What is an Industrial Sewing Machine? Juki. Available at: https://www.juki.co.jp/en/products/industrial/

- How to Analyze Data in Excel? Quick and Easy Steps. Available at: https://techbii.com/how-to-analyze-data-in-excel-quick-and-easy-steps/

- Zakharkevich, O., Paraska, O., Koshevko, J., Shvets, G., Shvets, A., Zhylenko, T. (2023). Development of a Mobile Application to Study Sewing Techniques for Manufacturing Fur and Leather Clothes. Fibres & Textiles in Eastern Europe, 31 (2), 1–10. https://doi.org/10.2478/ftee-2023-0011

- TechLab. Available at: https://play.google.com/store/apps/details?id=appinventor.ai_zbirvukladach.TL1&hl=uk&gl=US

- ISO 4916:1991 (1991). Textiles – Seam types – Classification and terminology. Printed in Switzerland/lmprime en Suisse, 64.

- Osvitnia prohrama «Tekhnolohiyi lehkoi promyslovosti» (riven mahistr) (2025). Available at: https://khmnu.edu.ua/wp-content/op/m/g15-ktshv-2025.pdf

- Poluda, S. N., Koval, T. V., Boksha, N. I. (2016). Tekhnolohiya shveinoho vyrobnytstva ta osnastka. Mukachevo: MDU, 93.

- Tran, K. P. (2022). Machine Learning and Probabilistic Graphical Models for Decision Support Systems. CRC Press. https://doi.org/10.1201/9781003189886

- He, Z., Tran, K.-P., Thomassey, S., Zeng, X., Xu, J., Yi, C. (2021). A deep reinforcement learning based multi-criteria decision support system for optimizing textile chemical process. Computers in Industry, 125, 103373. https://doi.org/10.1016/j.compind.2020.103373

- Di Domenico, A. (2023). Entanglement, CPT, and Neutral Kaons. CPT and Lorentz Symmetry, 74–78. https://doi.org/10.1142/9789811275388_0016

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oksana Zakharkevich, Julia Koshevko, Tetyana Zhylenko, Galina Shvets, Svitlana Kuleshova, Volodymyr Onofriichuk, Alona Diakova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.