Establishing the thermal changes in the foam layer of a biocomposite coating upon the addition of potassium nitrate

DOI:

https://doi.org/10.15587/1729-4061.2025.341605Keywords:

biocomposite coating, wood processing, coating swelling, foam coke layer, combustion productsAbstract

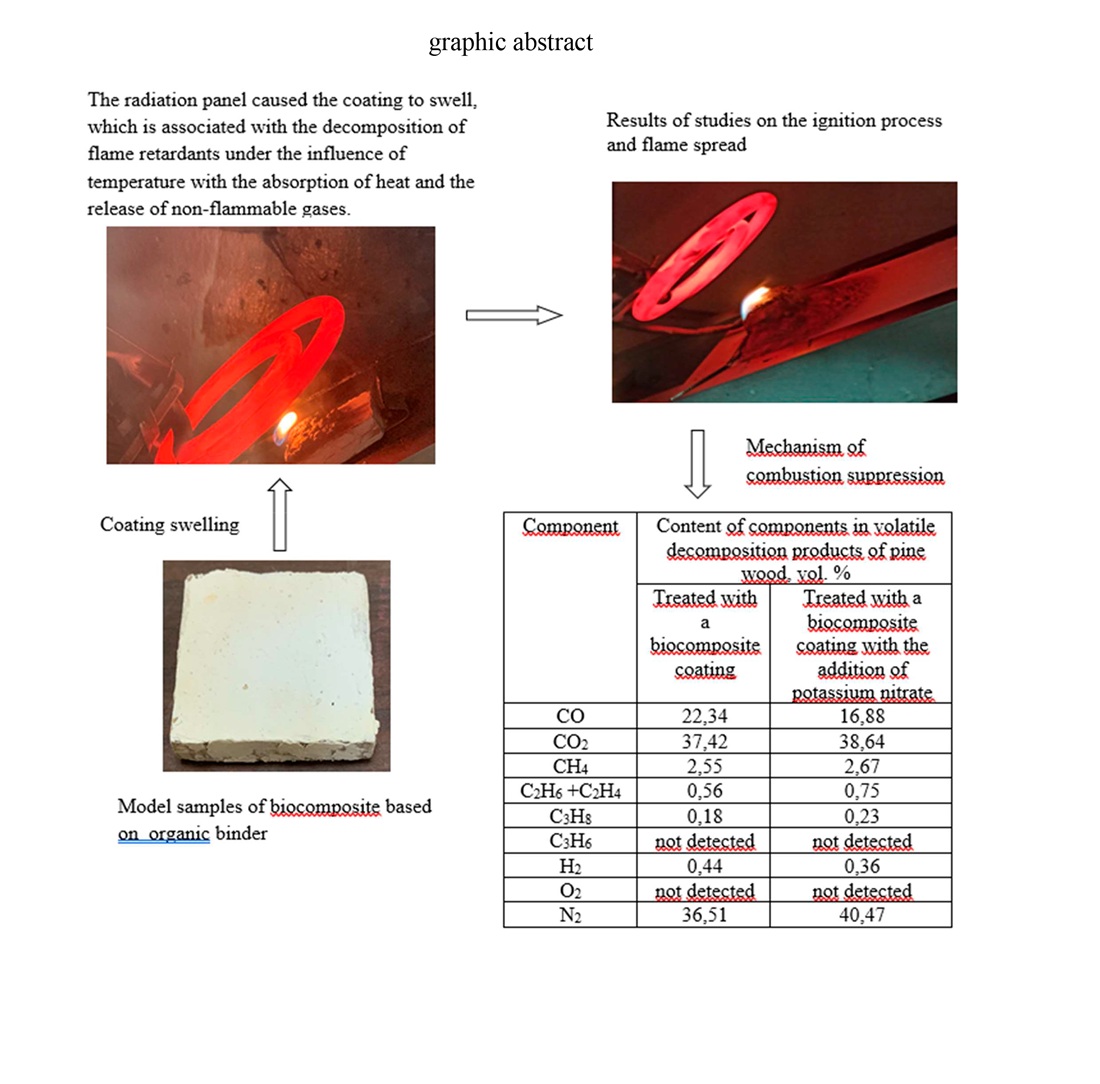

The object of research is the fire-retardant properties of biocomposite coating for wood when potassium nitrate is added during thermal action. The problem of fire resistance of biocomposites, which is aimed at increasing the efficiency of fire protection of wooden structures, consists in the formation of fire-resistant coatings by adding inorganic compounds. Such compounds are characterized by thermal stability, reduced smoke-forming ability and toxicity of combustion products and are mostly used as synergistic additives. Therefore, the work proves that during thermal action on wood treated with biocomposite coating, intensive formation of a foam coke layer began after 62 s to a height of 16 mm, which thermally insulated the wood. Instead, after the radiation panel was exposed to a sample of wood treated with a biocomposite coating with the addition of potassium nitrate, the formation of a foam coke layer began after 48 s of thermal exposure, the height of which was 15 mm, and the temperature of the flue gases did not exceed 100°C. At the same time, chemical reactions of potassium nitrate begin in the coating with the release of carbon monoxide, with the subsequent destruction of ammonium polyphosphate, which interacts with the biopolymer. The latter, in turn, affects the dehydration of pentaerythritol with the formation of coke, and the simultaneous decomposition of melamine causes the coke to foam. The composition of the gaseous products of thermal destruction of the biocomposite coating showed that when potassium nitrate was added, the amount of combustible gases decreased by more than 19%, and the amount of nitrogen increased by more than 10%. The practical significance is that the results obtained were taken into account when developing a fire-retardant coating for construction. Thus, there are grounds to argue about the possibility of effective protection of wood with a coating containing biopolymers

References

- Kwang Yin, J. J., Yew, M. C., Yew, M. K., Saw, L. H. (2019). Preparation of Intumescent Fire Protective Coating for Fire Rated Timber Door. Coatings, 9 (11), 738. https://doi.org/10.3390/coatings9110738

- Tang, G., Shang, C., Qin, Y., Lai, J. (2025). Current Advances in Flame-Retardant Performance of Tunnel Intumescent Fireproof Coatings: A Review. Coatings, 15 (1), 99. https://doi.org/10.3390/coatings15010099

- Nazrun, T., Hassan, M. K., Hasnat, M. R., Hossain, M. D., Ahmed, B., Saha, S. (2025). A Comprehensive Review on Intumescent Coatings: Formulation, Manufacturing Methods, Research Development, and Issues. Fire, 8 (4), 155. https://doi.org/10.3390/fire8040155

- Wang, F., Liu, H., Yan, L. (2021). Comparative Study of Fire Resistance and Char Formation of Intumescent Fire-Retardant Coatings Reinforced with Three Types of Shell Bio-Fillers. Polymers, 13 (24), 4333. https://doi.org/10.3390/polym13244333

- Bi, W., Tao, Z., Li, F., Nahar, Y., Jiang, C. (2025). Development of waterborne transparent intumescent coatings for timber buildings: Influence of phosphoric acid ratio. Construction and Building Materials, 493, 143225. https://doi.org/10.1016/j.conbuildmat.2025.143225

- Faryal, S., Zafar, M., Nazir, M. S., Ali, Z., Hussain, M., Muhammad Imran, S. (2022). The Synergic Effect of Primary and Secondary Flame Retardants on the Improvement in the Flame Retardant and Mechanical Properties of Thermoplastic Polyurethane Nanocomposites. Applied Sciences, 12 (21), 10866. https://doi.org/10.3390/app122110866

- Ai, L., Chen, S., Zeng, J., Yang, L., Liu, P. (2019). Synergistic Flame Retardant Effect of an Intumescent Flame Retardant Containing Boron and Magnesium Hydroxide. ACS Omega, 4 (2), 3314–3321. https://doi.org/10.1021/acsomega.8b03333

- Wang, G., Li, W., Bai, S., Wang, Q. (2019). Synergistic Effects of Flame Retardants on the Flammability and Foamability of PS Foams Prepared by Supercritical Carbon Dioxide Foaming. ACS Omega, 4 (5), 9306–9315. https://doi.org/10.1021/acsomega.9b00321

- Lin, F., Zhang, M., Li, X., Mao, S., Wei, Y. (2022). Synergistic Effects of Diatoms on Intumescent Flame Retardant High Impact Polystyrene System. Polymers, 14 (20), 4453. https://doi.org/10.3390/polym14204453

- Li, L., Shao, X., Zhao, Z., Liu, X., Jiang, L., Huang, K., Zhao, S. (2020). Synergistic Fire Hazard Effect of a Multifunctional Flame Retardant in Building Insulation Expandable Polystyrene through a Simple Surface-Coating Method. ACS Omega, 5 (1), 799–807. https://doi.org/10.1021/acsomega.9b03541

- Li, L., Huang, Y., Tang, W., Zhang, Y., Qian, L. (2022). Synergistic Effect between Piperazine Pyrophosphate and Melamine Polyphosphate in Flame Retardant Coatings for Structural Steel. Polymers, 14 (18), 3722. https://doi.org/10.3390/polym14183722

- Hobson, J., Yin, G.-Z., Yu, X., Zhou, X., Prolongo, S. G., Ao, X., Wang, D.-Y. (2022). Synergistic Effect of Cerium Oxide for Improving the Fire-Retardant, Mechanical and Ultraviolet-Blocking Properties of EVA/Magnesium Hydroxide Composites. Materials, 15 (17), 5867. https://doi.org/10.3390/ma15175867

- Tsapko, Y., Tsapko, A., Likhnyovskyi, R., Bielikova, K., Berdnyk, O., Gavryliuk, A. et al. (2025). Establishing regularities of fire protection of wood by a composite coating with a biopolymer. Eastern-European Journal of Enterprise Technologies, 3 (10 (135)), 16–25. https://doi.org/10.15587/1729-4061.2025.332443

- Kryvenko, P., Tsapko, Y., Guzii, S., Kravchenko, A. (2016). Determination of the effect of fillers on the intumescent ability of the organic-inorganic coatings of building constructions. Eastern-European Journal of Enterprise Technologies, 5 (10 (83)), 26–31. https://doi.org/10.15587/1729-4061.2016.79869

- Tsapko, Y., Tsapko, A., Lomaha, V., Illiuchenko, P., Berdnyk, O., Likhnyovskyi, R. et al. (2025). Establishing patterns in the formation of biocomposites for thermal insulation of building structures. Eastern-European Journal of Enterprise Technologies, 4 (10 (136)), 56–64. https://doi.org/10.15587/1729-4061.2025.337401

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of Polymer Science Part A-2: Polymer Physics, 7 (10), 1761–1773. https://doi.org/10.1002/pol.1969.160071012

- Tsapko, Y., Tsapko, А. (2017). Establishment of the mechanism and fireproof efficiency of wood treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 3 (10 (87)), 50–55. https://doi.org/10.15587/1729-4061.2017.102393

- Kolya, H., Kang, C.-W. (2024). Eco-Friendly Polymer Nanocomposite Coatings for Next-Generation Fire Retardants for Building Materials. Polymers, 16 (14), 2045. https://doi.org/10.3390/polym16142045

- Tsapko, Y., Tkachenko, T., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Bereznutska, Y. et al. (2024). Defining patterns in the fire protection of wood with reactive coating. Eastern-European Journal of Enterprise Technologies, 6 (10 (132)), 55–63. https://doi.org/10.15587/1729-4061.2024.317334

- Yan, Y., Dong, S., Jiang, H., Hou, B., Wang, Z., Jin, C. (2022). Efficient and Durable Flame-Retardant Coatings on Wood Fabricated by Chitosan, Graphene Oxide, and Ammonium Polyphosphate Ternary Complexes via a Layer-by-Layer Self-Assembly Approach. ACS Omega, 7 (33), 29369–29379. https://doi.org/10.1021/acsomega.2c03624

- Tsapko, Y., Tsapko, А., Likhnyovskyi, R., Shumbar, K., Slutska, O., Berdnyk, O. et al. (2025). Establishing the rules of formation of fire-resistant biocomposites for building materials. Eastern-European Journal of Enterprise Technologies, 2 (10 (134)), 35–43. https://doi.org/10.15587/1729-4061.2025.326655

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Аleksii Tsapko, Ruslan Likhnyovskyi, Oksana Berdnyk, Maryna Sukhanevych, Oksana Slutska, Anna Borysova, Oleksandr Dotsenko, Anduij Lyn, Oles Lastivka

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.