Development of geopolymer concrete formulations based on activated stone processing sludge to reduce natural resource consumption

DOI:

https://doi.org/10.15587/1729-4061.2025.341720Keywords:

stone-processing sludge, geopolymer concrete, waste utilization, mechanical strength, ultrasonic properties, material nano activationAbstract

This study investigates concrete mixtures modified by partial or complete replacement of cement and sand with granite and gabbro sludge from stone-processing plants, activated with a 12M NaOH solution to improve their mechanical properties and microstructure.

The task addressed relates to the excessive accumulation of sludge waste from the stone-processing industry, which pollutes the environment and predetermines the need to reduce the consumption of natural resources (cement and sand) in concrete production. This production is accompanied by high CO2 emissions and significant costs. All these factors necessitate designing environmentally friendly and economically viable construction materials.

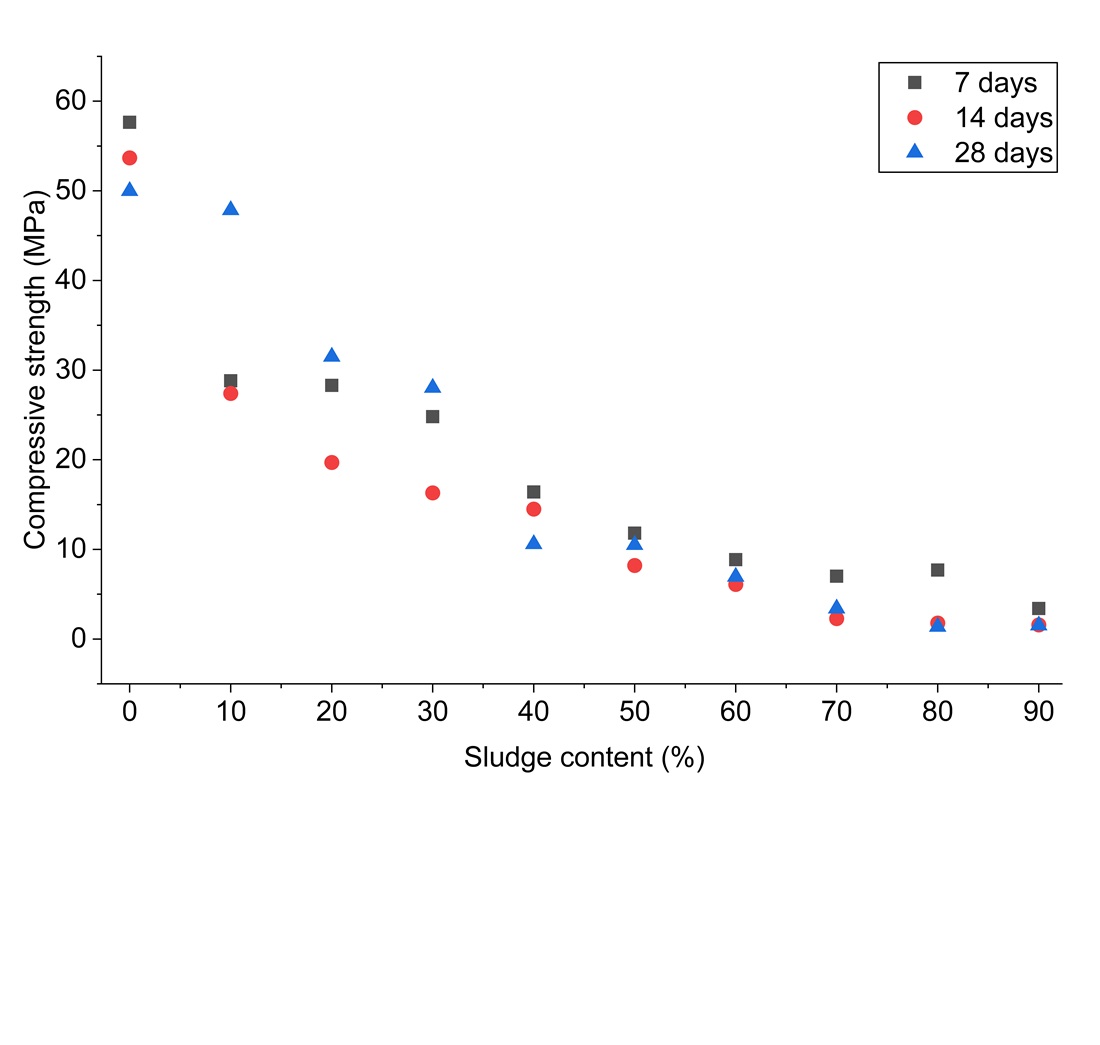

The study investigated the effect of replacing cement (0–100%) and sand (0–100%) with a mixture of granite and gabbro sludge on compressive strength and ultrasonic pulse velocity after 7, 14, and 28 days of curing. Replacing up to 30% of sand provides a compressive strength of 45–50 MPa while replacing up to 20% of cement provides 30–32 MPa on day 28, meeting structural requirements (>10 MPa). The ultrasonic velocity (4200–4300 m/s at 30% sand replacement and 3800–4000 m/s at 20% cement replacement) indicates the preservation of a dense structure.

Distinguishing features of the results are attributed to the combination of granite and gabbro sludge activated with NaOH that produces a microfiller effect and enables pozzolanic activity. This makes it possible to reduce sand consumption by 30% and cement by 20% without a significant loss of strength. Unlike conventional mixtures or solutions using only one type of sludge, strength reduction proceeds more slowly due to fewer microcracks.

The results are suitable for producing environmentally friendly concrete for road and residential construction under moderately aggressive environmental conditions. The optimal replacement (30% sand or 20% cement) is effective under both laboratory and industrial conditions, provided that the sludge has a homogeneous composition and is activated with NaOH

References

- Lozano-Lunar, A., Dubchenko, I., Bashynskyi, S., Rodero, A., Fernández, J. M., Jiménez, J. R. (2020). Performance of self-compacting mortars with granite sludge as aggregate. Construction and Building Materials, 251, 118998. https://doi.org/10.1016/j.conbuildmat.2020.118998

- Medina, G., Sáez del Bosque, I. F., Frías, M., Sánchez de Rojas, M. I., Medina, C. (2018). Durability of new recycled granite quarry dust-bearing cements. Construction and Building Materials, 187, 414–425. https://doi.org/10.1016/j.conbuildmat.2018.07.134

- Chajec, A. (2023). The use of granite powder waste in cementitious composites. Journal of Materials Research and Technology, 25, 4761–4783. https://doi.org/10.1016/j.jmrt.2023.06.253

- Medina, G., Sáez del Bosque, I. F., Frías, M., Sánchez de Rojas, M. I., Medina, C. (2020). Sulfate Resistance in Cements Bearing Ornamental Granite Industry Sludge. Materials, 13 (18), 4081. https://doi.org/10.3390/ma13184081

- Surra, E., Sousa, J., Correia, M., Carvalheiras, J., Labrincha, J. A., Marques, J. C. et al. (2023). Technical, Environmental, and Cost Assessment of Granite Sludge Valorisation. Applied Sciences, 13(7), 4513. https://doi.org/10.3390/app13074513

- Duan, D., Liao, H., Wang, J., Cheng, F. (2023). Hydration characteristics of tailing mud–42.5 OPC composite cementitious system and its application to dry-mixed mortar. Journal of Building Engineering, 70, 106294. https://doi.org/10.1016/j.jobe.2023.106294

- Leonets, I., Kyrylenko, N., Mykytenko, S., Syroid, Y. (2024). Impact Assessment of Natural Stone Processing Techniques on the Grain Composition of Sludge Admixtures for Press Powder. Geoheritage, 16 (4). https://doi.org/10.1007/s12371-024-01030-z

- Korobiichuk, I., Shamray, V., Korobiichuk, V., Kryvoruchko, A., Iskov, S.; Szewczyk, R., Zieliński, C., Kaliczyńska, M. (Eds.) (2021). Dose Measurement of Flocculants in Water Treatment of Stone Processing Plants. Automation 2021: Recent Achievements in Automation, Robotics and Measurement Techniques. Cham: Springer, 387–394. https://doi.org/10.1007/978-3-030-74893-7_34

- Shamrai, V., Leonets, I., Melnyk-Shamrai, V., Patseva, I., Naumov, Y. (2024). Reuse of stone working enterprise slurry in geopolymer and concrete products. Mining of Mineral Deposits, 18 (4), 10–17. https://doi.org/10.33271/mining18.04.010

- Sadek, D. M., El-Attar, M. M., Ali, H. A. (2016). Reusing of marble and granite powders in self-compacting concrete for sustainable development. Journal of Cleaner Production, 121, 19–32. https://doi.org/10.1016/j.jclepro.2016.02.044

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Shamrai, Valentyn Korobiichuk, Iryna Leonets, Viktoriia Melnyk-Shamrai, Yaroslav Naumov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.