Determining the structural features of the chromium and copper alloy material obtained by electron beam welding

DOI:

https://doi.org/10.15587/1729-4061.2025.341821Keywords:

weld, electron beam welding, microstructure, eutectic, phase formations, temperature gradientAbstract

This study considers a welded joint between copper and chromium. The task addressed is to enable the formation of a copper and chromium joint based on the selection of the alloy material's optimal structure.

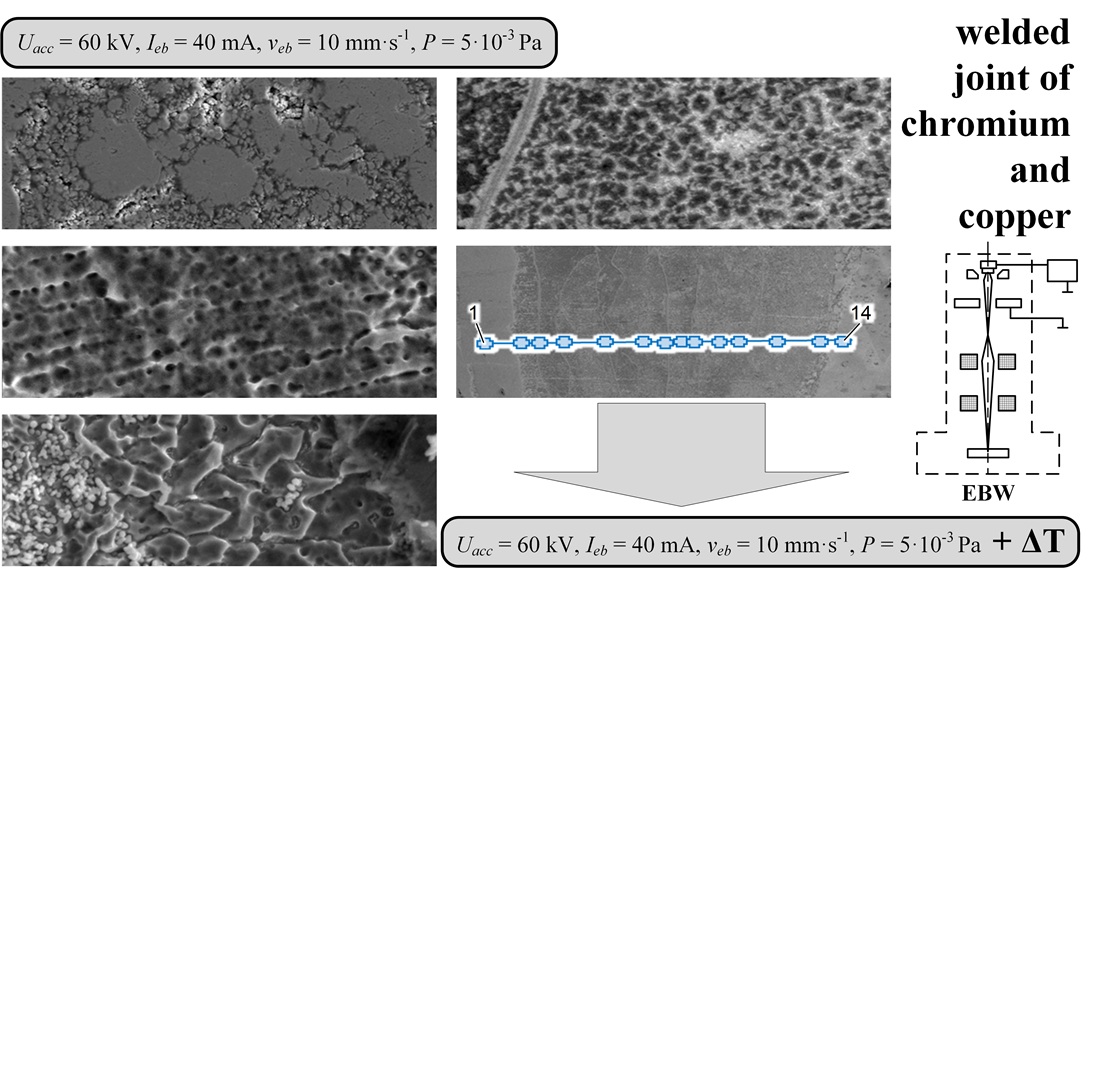

Based on scanning electron microscopy, micro-X-ray spectral analysis, and microhardness measurement, the properties of the welded joint material in a copper and chromium joint were investigated. The joint was obtained by electron beam welding by preheating one of the metals while removing additional heat supply from the other. It was established that a moving electron beam leads to the formation of different types of microstructure in the alloy material with significant concentration heterogeneity: quasi-dendritic; linearly elongated; scaly; cellular; quasi-spherical.

Welding with a stationary, linearly deployed along the joint, electron beam with preheating of one of the metals and providing additional heat removal from the other enables the formation of a concentrically uniform weld with a quasi-spherical microstructure of copper-chromium eutectic.

The directional nature of the copper-based grains, which are elongated in the direction across the welded joint, which corresponds to the direction of additional heat removal from one of the welded metals, was revealed. The material obtained by a stationary, linearly deployed along the joint, electron beam under the mode Uacc = 60 kV, Ieb = 40 mA, P = 5·10-3 Pa for a duration of 7 seconds with preheating of chromium to 900°C and providing additional heat removal from copper was determined as the alloy material of the welded joint between copper and chromium with an optimal structure.

The results could be used while making copper-chromium joints by fusion welding in a vacuum with regulation of the speed of movement and focusing of the source of thermal energy supply

References

- Kharchenko, G. K., Fal'chenko, Yu. V., Novomlinets, O. A., Gorban', V. F. (2002). Diffuzionnaya svarka v vakuume khroma s med'yu. Avtomaticheskaya svarka, 7 (592), 41–42. Available at: http://dspace.nbuv.gov.ua/handle/123456789/89012

- Paul, H., Chulist, R., Lityńska-Dobrzyńska, L., Prażmowski, M., Faryna, M., Mania, I. et al. (2021). Interfacial reactions and microstructure related properties of explosively welded tantalum and steel sheets with copper interlayer. Materials & Design, 208, 109873. https://doi.org/10.1016/j.matdes.2021.109873

- Kharchenko, G. K., Fal'chenko, Yu. V., Arsenyuk, V. V., Polovetskiy, E. V. (2002). Udarnaya svarka v vakuume alyuminiya s med'yu. Avtomaticheskaya svarka, 9 (594), 50–51. Available at: http://dspace.nbuv.gov.ua/handle/123456789/89045

- Singh, R., Singh, S., Kanigalpula, P. K. C., Saini, J. S. (2020). Electron beam welding of precipitation hardened CuCrZr alloy: Modeling and experimentation. Transactions of Nonferrous Metals Society of China, 30 (8), 2156–2169. https://doi.org/10.1016/s1003-6326(20)65368-7

- Ansara, I., Ivanchenko, V., Dreval, L. (2016). Cr-Cu Binary Phase Diagram Evaluation. MSI Eureka, 68, 20.19588.2.8. https://doi.org/10.7121/msi-eureka-20.19588.2.8

- Zhou, Z., Zhou, T., Chai, L., Tu, J., Wang, Y., Huang, W. et al. (2015). Microstructure and Liquid Phase Separation of CuCr Alloys Treated by High Current Pulsed Electron Beam. Materials Research, 18 (suppl 1), 34–39. https://doi.org/10.1590/1516-1439.323714

- Shan, L., Yang, L., Wang, Y. (2022). Improving the high temperature mechanical performance of Cu–Cr alloy induced by residual nano-sized Cr precipitates. Materials Science and Engineering: A, 845, 143250. https://doi.org/10.1016/j.msea.2022.143250

- ISO 10387:1994(en). Metal chrome – Specification and conditions of delivery. Available at: https://www.iso.org/ru/standard/18451.html

- DSTU HOST 859:2003. Mid. Marky (HOST 859-2001, IDT). Available at: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=93267

- Yarmolenko, M. V. (2018). Analytically Solvable Differential Diffusion Equations Describing the Intermediate Phase Growth. Metallofizika I Noveishie Tekhnologii, 40 (9), 1201–1207. https://doi.org/10.15407/mfint.40.09.1201

- Korzhyk, V. M., Khaskin, V. Yu., Kvasnytskyi, V. V., Ganushchak, O. V., Hos, I. D., Peleshenko, S. I. et al. (2023). Preparing Permanent Joints of Titanium Alloys with Steel (A Review). Materials Science, 59 (2), 129–137. https://doi.org/10.1007/s11003-024-00753-2

- Liu, L., Sun, D., Huang, T., Zhang, Y., Li, Y., Zhang, J., Fu, H. (2018) Directional Solidification Under High Thermal Gradient and Its Application in Superalloys Processing. Acta Metallurgica Sinica, 54 (5), 615–626. https://doi.org/10.11900/0412.1961.2018.00075

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Eduard Vrzhyzhevskyi, Valery Kostin, Tatjana Taranova, Anastasiia Zvorykina, Volodymyr Zvorykin, Leonid Zvorykin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.