Identifying mechanisms behind crack formation and destruction of the damper winding of a capsule-type hydrogenerator in the presence of static rotor eccentricity

DOI:

https://doi.org/10.15587/1729-4061.2025.342108Keywords:

capsule hydrogenerator, rotor eccentricity, rods damage, damper winding, thermomechanical stressesAbstract

This study investigates a capsule-type SGK 538/160–70M hydrogenerator with a rated power of 23 MVA. The task addressed relates to crack initiation and failure of the damper winding in the hydrogenerator in the presence of rotor static eccentricity.

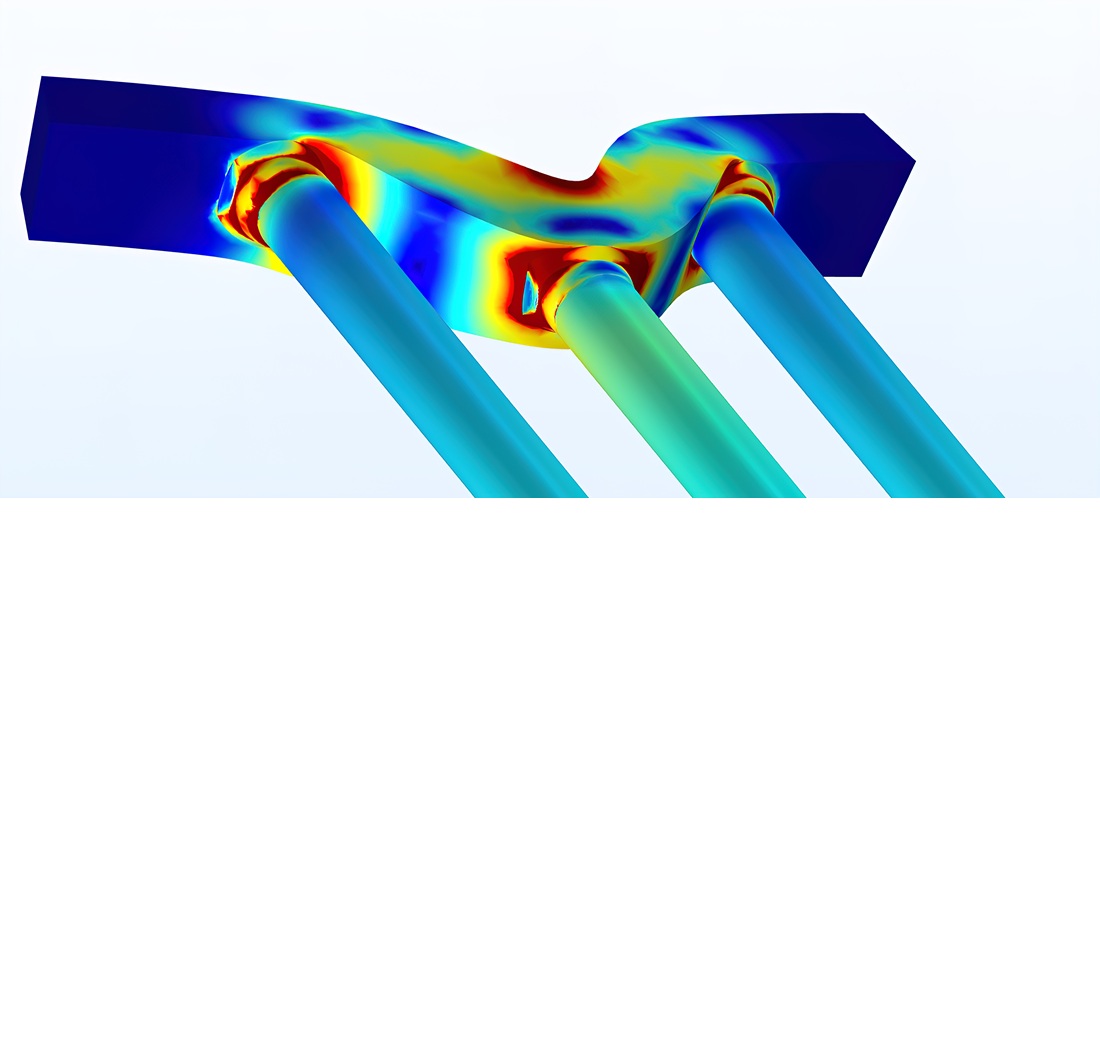

A three-dimensional field-based mathematical model of the electromagnetic-thermal-mechanical interaction has been constructed to evaluate the distributions of currents, temperatures, and thermomechanical stresses in the damper winding segment and in the brazed joints of rods.

It is shown that the occurrence and evolution of rotor static eccentricity constitute one of the essential causes of catastrophic damages and failures in hydrogenerators of this type. It has been determined that, under rotor static eccentricity of ε = 0.83, the local stresses in the joint of the central rod increase by a factor of ~3.2 (up to ≈ 540 MPa). This value exceeds the tensile strength of copper and explains rod ruptures and avalanche-type failure of the segment. In addition, it was established that the existence and localization of cracks in brazed joints significantly affect the bending (deformation) behavior of the pole damper winding segment.

The results could be applied to estimate the service life and to upgrade large slow-speed synchronous hydrogenerators (including capsule types). Specifically, under the following conditions:

a) existing or expected eccentricities;

b) high thermal gradients in the end/short-circuiting parts of the damper winding;

c) operation with frequent starts/stops or cooling modes close to limiting values.

The effective engineering measures that have been proposed, such as improving the mobility of rods in slots; revising the number and diameters of rods; applying high-strength materials, could be implemented in retrofitting projects and when repairing the rotor

References

- Mostafaei, M., Faiz, J. (2021). An overview of various faults detection methods in synchronous generators. IET Electric Power Applications, 15 (4), 391–404. https://doi.org/10.1049/elp2.12031

- Ehya, H., Nysveen, A., Nilssen, R., Liu, Y. (2021). Static and dynamic eccentricity fault diagnosis of large salient pole synchronous generators by means of external magnetic field. IET Electric Power Applications, 15 (7), 890–902. https://doi.org/10.1049/elp2.12068

- Vaskovsky, Yu. M., Geraskin, O. A. (2021). Influence of regime and operational factors on the damper system of the sali-ent-pole synchronous machine rotor. Tekhnichna Elektrodynamika, 2021 (2), 47–57. https://doi.org/10.15407/techned2021.02.047

- Vaskovskii, Yu. M., Geraskin, O. A. (2020). The effect of rotor eccentricity on damper winding of 23 MVA capsular hydraulic-turbine generator. Hidroenerhetyka Ukrainy, 1-2, 59–64. Available at: https://uhe.gov.ua/sites/default/files/2020-07/15.pdf

- Vaskovskii, Yu. M., Geraskin, O. A., Tatarinov, K. M. (2020). Simulation of thermomechanical stresses of the dampper winding of capsular hydrogenerator when the rotor eccentricity appears. Hidroenerhetyka Ukrainy, 3-4, 64–67. Available at: https://uhe.gov.ua/sites/default/files/2020-12/17.pdf

- Zhou, Z.-T., Yang, Y., Xiao, K., Fan, Z.-N., Bian, Z.-Y., Wen, K. et al. (2020). Analysis and Treatment of an Overheated Ablated Fault on the Pole Shoe Surface of a Large Tubular Hydro-Generator. IEEE Access, 8, 127929–127938. https://doi.org/10.1109/access.2020.3008253

- Zhang, S., Li, W., Li, J., Wang, L., Zhang, X. (2014). Research on Flow Rule and Thermal Dissipation Between the Rotor Poles of a Fully Air-cooled Hydro-generator. IEEE Transactions on Industrial Electronics, 62 (6), 3430–3437. https://doi.org/10.1109/tie.2014.2366723

- Jichao, H., Yufei, L., Jiechen, D., Yutian, S., Baojun, G., Weili, L. (2021). Thermal Modeling and Experimental Validation in the Rotor Region of Hydrogenerator With Different Rotor Structures. IEEE Access, 9, 120001–120009. https://doi.org/10.1109/access.2021.3098319

- Fan, Z., Liao, Y., Han, L., Xie, L. (2013). No-Load Voltage Waveform Optimization and Damper Bars Heat Reduction of Tubular Hydrogenerator by Different Degree of Adjusting Damper Bar Pitch and Skewing Stator Slot. IEEE Transactions on Energy Conversion, 28 (3), 461–469. https://doi.org/10.1109/tec.2013.2259628

- Xu, M., Hu, W., Zhou, Z., Fan, Z. (2024). The influence of electromagnetic field models on the damper winding loss and heat calculation results of tubular hydro‐generator. Electronics Letters, 60 (5). https://doi.org/10.1049/ell2.13144

- Bian, Z., Zhou, Z., Fan, Z. (2021). No‐load voltage and damper winding loss and heat analysis of the pole shoe and damper winding centre line shifted structure of tubular hydro‐generators. Electronics Letters, 57 (18), 691–693. https://doi.org/10.1049/ell2.12227

- Qiu, H., Fan, X., Yi, R., Feng, J., Wu, J., Yang, C., Zhao, H. (2017). Eddy current density asymmetric distribution of damper bars in bulb tubular turbine generator. Archives of Electrical Engineering, 66 (3), 571–581. https://doi.org/10.1515/aee-2017-0043

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olexandr Geraskin, Yurii Haidenko, Vadim Chumack, Vladislav Mihaylenko, Yevhenii Trotsenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.