Designing and determining the physical-chemical properties of lithium aluminosilicate glass-ceramic materials for armor protection

DOI:

https://doi.org/10.15587/1729-4061.2025.346699Keywords:

aluminosilicate glass-ceramic materials, armor element, impact resistance, wave propagation velocity, physical-mechanical propertiesAbstract

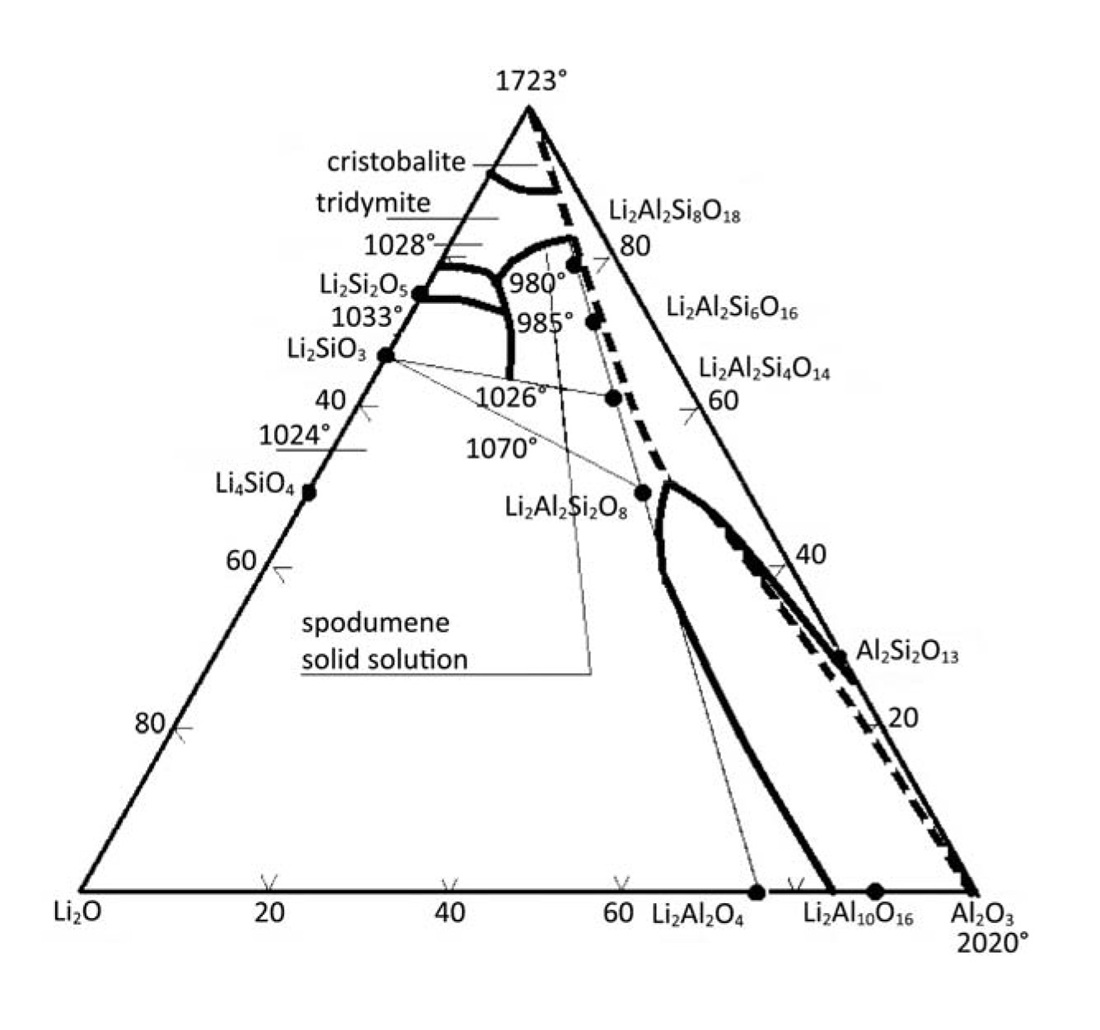

This study investigates spodumene glassy materials in the R2O-RO-RO2-R2O3-Li2O-CaO-P2O5-SiO2 system.

The task addressed is to obtain lightweight glassy materials with high microhardness and resistance to cracking, while maintaining a low apparent density and moderate energy consumption during manufacture. DTA/DSC, XRD, and optical microscopy were used to examine the structure and phase composition of samples obtained by one- and two-stage heat treatment.

Based on the research results, a series of compositions were developed; the structural characteristics of the glass matrix were determined for them. The resulting data show that the low-temperature two-stage heat treatment (nucleation at 530°C, crystallization at 850…900°C) contributes to the formation of a fine-grained structure, in which β-spodumene predominates (80…85 vol.%). Compared to the single-step process, HV and H increased by 9…20%, K1C by 20…31%, and E by 25%. This effect can be explained by metastable micro liquefaction and early nucleation, leading to the formation of highly dense, fine-grained prismatic β-spodumene grains that inhibit crack propagation.

The choice of oxides and composition of nucleators (TiO2, ZrO2) is crucial. The introduction of fluorides and small amounts of rare-earth oxides reduces the melt viscosity and nucleation temperature. The addition of P2O5 promotes localized micro liquefaction of the fine-grained morphology of the target phase. These factors reconstruct the glassy phase and contribute to mechanical strengthening, distributing stresses more evenly within the finely dispersed crystalline matrix.

The practical significance of this study is that the obtained spodumene-containing composite materials have both high mechanical properties (HV = 7.9…9.2 GPa; K1C = 1.8…3.4 MPa·m0.5) and a reasonably low apparent density (ρ = 2370…2450 kg/m3) compared to other protective materials. These materials are suitable for the manufacture of lightweight individual bulletproof composite components.

References

- Venkateswaran, C., Sreemoolanadhan, H., Vaish, R. (2021). Lithium aluminosilicate (LAS) glass-ceramics: a review of recent progress. International Materials Reviews, 67 (6), 620–657. https://doi.org/10.1080/09506608.2021.1994108

- LaSalvia, J. C. (2015). Advances in ceramic armor. Wiley.

- Fejdyś, M., Kośla, K., Kucharska-Jastrząbek, A., Łandwijt, M. (2020). Influence of ceramic properties on the ballistic performance of the hybrid ceramic–multi-layered UHMWPE composite armour. Journal of the Australian Ceramic Society, 57 (1), 149–161. https://doi.org/10.1007/s41779-020-00516-7

- Dresch, A. B., Venturini, J., Arcaro, S., Montedo, O. R. K., Bergmann, C. P. (2021). Ballistic ceramics and analysis of their mechanical properties for armour applications: A review. Ceramics International, 47 (7), 8743–8761. https://doi.org/10.1016/j.ceramint.2020.12.095

- Xiang, S., Ma, L., Yang, B., Dieudonne, Y., Pharr, G. M., Lu, J. et al. (2019). Tuning the deformation mechanisms of boron carbide via silicon doping. Science Advances, 5 (10). https://doi.org/10.1126/sciadv.aay0352

- Shen, Z., Hu, D., Yang, G., Han, X. (2019). Ballistic reliability study on SiC/UHMWPE composite armor against armor-piercing bullet. Composite Structures, 213, 209–219. https://doi.org/10.1016/j.compstruct.2019.01.078

- Sajdak, M., Kornaus, K., Zientara, D., Moskała, N., Komarek, S., Momot, K. et al. (2024). Processing, Microstructure and Mechanical Properties of TiB2-MoSi2-C Ceramics. Crystals, 14 (3), 212. https://doi.org/10.3390/cryst14030212

- Chiu, Y.-J., Yen, C.-Y., Chiang, M.-S., Chen, G.-J., Jian, S.-R., Wang, C., Kao, H.-L. (2017). Mechanical Properties and Fracture Toughness of AlN Thin Films Deposited Using Helicon Sputtering. Nanoscience and Nanotechnology Letters, 9 (4), 562–566. https://doi.org/10.1166/nnl.2017.2357

- Gallo, L. S., Villas Boas, M. O. C., Rodrigues, A. C. M., Melo, F. C. L., Zanotto, E. D. (2019). Transparent glass–ceramics for ballistic protection: materials and challenges. Journal of Materials Research and Technology, 8 (3), 3357–3372. https://doi.org/10.1016/j.jmrt.2019.05.006

- Li, M., Xiong, C., Ma, Y., Jiang, H. (2022). Study on Crystallization Process of Li2O–Al2O3–SiO2 Glass-Ceramics Based on In Situ Analysis. Materials, 15 (22), 8006. https://doi.org/10.3390/ma15228006

- Dittmer, M., Ritzberger, C., Höland, W., Rampf, M. (2018). Controlled precipitation of lithium disilicate (Li2Si2O5) and lithium niobate (LiNbO3) or lithium tantalate (LiTaO3) in glass-ceramics. Journal of the European Ceramic Society, 38 (1), 263–269. https://doi.org/10.1016/j.jeurceramsoc.2017.08.032

- Glatz, P., Comte, M., Montagne, L., Doumert, B., Cousin, F., Cormier, L. (2020). Structural evolution at short and medium range distances during crystallization of a P2O5-Li2O-Al2O3-SiO2 glass. Journal of the American Ceramic Society, 103 (9), 4969–4982. https://doi.org/10.1111/jace.17189

- Abdullah, A. A., Dlugogorski, B. Z., Oskierski, H. C., Senanayake, G. (2024). Kinetics of spodumene calcination (α-LiAlSi2O6). Minerals Engineering, 216, 108902. https://doi.org/10.1016/j.mineng.2024.108902

- Savvova, O. V., Babich, O. V., Voronov, G. K., Ryabinin, S. O. (2017). High-Strength Spodumene Glass-Ceramic Materials. Strength of Materials, 49 (3), 479–486. https://doi.org/10.1007/s11223-017-9890-4

- Savvova, O. V., Babich, O. V., Voronov, H. K., Riabinin, S. O. (2017). Vysokomitsni spodumenovi sklokrystalichni materialy. Problemy mitsnosti, 3, 167–175. Available at: https://nasplib.isofts.kiev.ua/items/6a48d4df-eee2-4aeb-9a2a-fab8af8a5c49

- NATO AEP-55 STANAG 4569 Protection levels for Occupants of Logistic and Light Armoured Vehicles. NATO. Available at: https://ballistics.com.au/wp-content/uploads/2020/05/NATO_AEP-55_STANAG_4569_standards.pdf

- Yu, X., Wang, M., Rao, Y., Xu, Y., Xia, M., Zhang, X., Lu, P. (2023). Unveiling the evolution of early phase separation induced by P2O5 for controlling crystallization in lithium disilicate glass system. Journal of the European Ceramic Society, 43 (12), 5381–5389. https://doi.org/10.1016/j.jeurceramsoc.2023.05.006

- Zhou, Z., He, F., Shi, M., Xie, J., Wan, P., Cao, D., Zhang, B. (2022). Influences of Al2O3 content on crystallization and physical properties of LAS glass-ceramics prepared from spodumene. Journal of Non-Crystalline Solids, 576, 121256. https://doi.org/10.1016/j.jnoncrysol.2021.121256

- Lisachuk, G. V., Ryshenko, M. I., Belostockaya, L. A. (2008). Steklokristallicheskie pokrytiya po keramike. Kharkiv: NTU" HPI, 480. Available at: https://library.kpi.kharkov.ua/files/new_postupleniya/stkrpo.pdf

- Trusova, Yu. D. (2004). Empiricheskiy kriteriy kristallizacionnoy sposobnosti mnogokomponentnyh oksidnyh rasplavov. Vestnik NTU «KhPI», 34, 38–44.

- Savvova, О., Voronov, H., Babich, О., Fesenko, O., Riabinin, S., Bieliakov, R. (2020). Solid Solutions Formation Mechanism in Cordierite-Mullite Glass Materials During Ceramization. Chemistry & Chemical Technology, 14 (4), 583–589. https://doi.org/10.23939/chcht14.04.583

- Savvova, O. V., Ryabinin, S. A., Svitlichniy, E. A., Voronov, G. K., Fesenko, A. I. (2019). Selection justification of methods for obtaining glass-ceramic materials. Keramika: Nauka i Zhyttia, 3 (44), 8–15. https://doi.org/10.26909/csl.3.2019.1

- Riabinin, S., Zakharov, A., Maizelis, A., Prytychenko, H. (2024). Determination of prospective directions for the improvement of materials for individual armor protection. Bulletin of the National Technical University “KhPI”. Series: Chemistry, Chemical Technology and Ecology, 2 (10), 53–60. https://doi.org/10.20998/2079-0821.2023.02.09

- ISO 23146:2012. Fine ceramics (advanced ceramics, advanced technical ceramics) — Test methods for fracture toughness of monolithic ceramics — Single-edge V-notch beam (SEVNB) method. ISO. Available at: https://www.iso.org/standard/62093.html

- EN 1288-1:2000. Glass in building - Determination of the bending strength of glass - Part 1: Fundamentals of testing glass. Available at: https://standards.iteh.ai/catalog/standards/cen/5c0c5441-ce5e-44f4-ae8e-b187edd43653/en-1288-1-2000

- ASTM C730-98(2021). Standard Test Method for Knoop Indentation Hardness of Glass. ASTM International. Available at: https://www.astm.org/c0730-98r21.html

- Inage, K., Akatsuka, K., Iwasaki, K., Nakanishi, T., Maeda, K., Yasumori, A. (2020). Effect of crystallinity and microstructure on mechanical properties of CaO-Al2O3-SiO2 glass toughened by precipitation of hexagonal CaAl2Si2O8 crystals. Journal of Non-Crystalline Solids, 534, 119948. https://doi.org/10.1016/j.jnoncrysol.2020.119948

- Fedorenko, O. Yu. et al. (2015). Khimichna tekhnolohiya tuhoplavkykh nemetalevykh i sylikatnykh materialiv u prykladakh i zadachakh. Ch. 2. Fizyko-khimichni systemy, fazovi rivnovahy, termodynamika, resurso- ta enerhozberezhennia v tekhnolohiyi tuhoplavkykh nemetalevykh i sylikatnykh materialiv. Kharkiv, 336. Available at: https://library.kpi.kharkov.ua/uk/chemistry_himtehnol

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Sviatoslav Riabinin, Artem Zakharov, Mykyta Maistat, Stanislav Lihezin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.