Establishing patterns in the formation of properties of fire-resistant biocomposites based on a hybrid binder

DOI:

https://doi.org/10.15587/1729-4061.2025.348144Keywords:

fragility of gypsum products, hybrid binder, wood sawdust, coke layer, fire resistanceAbstract

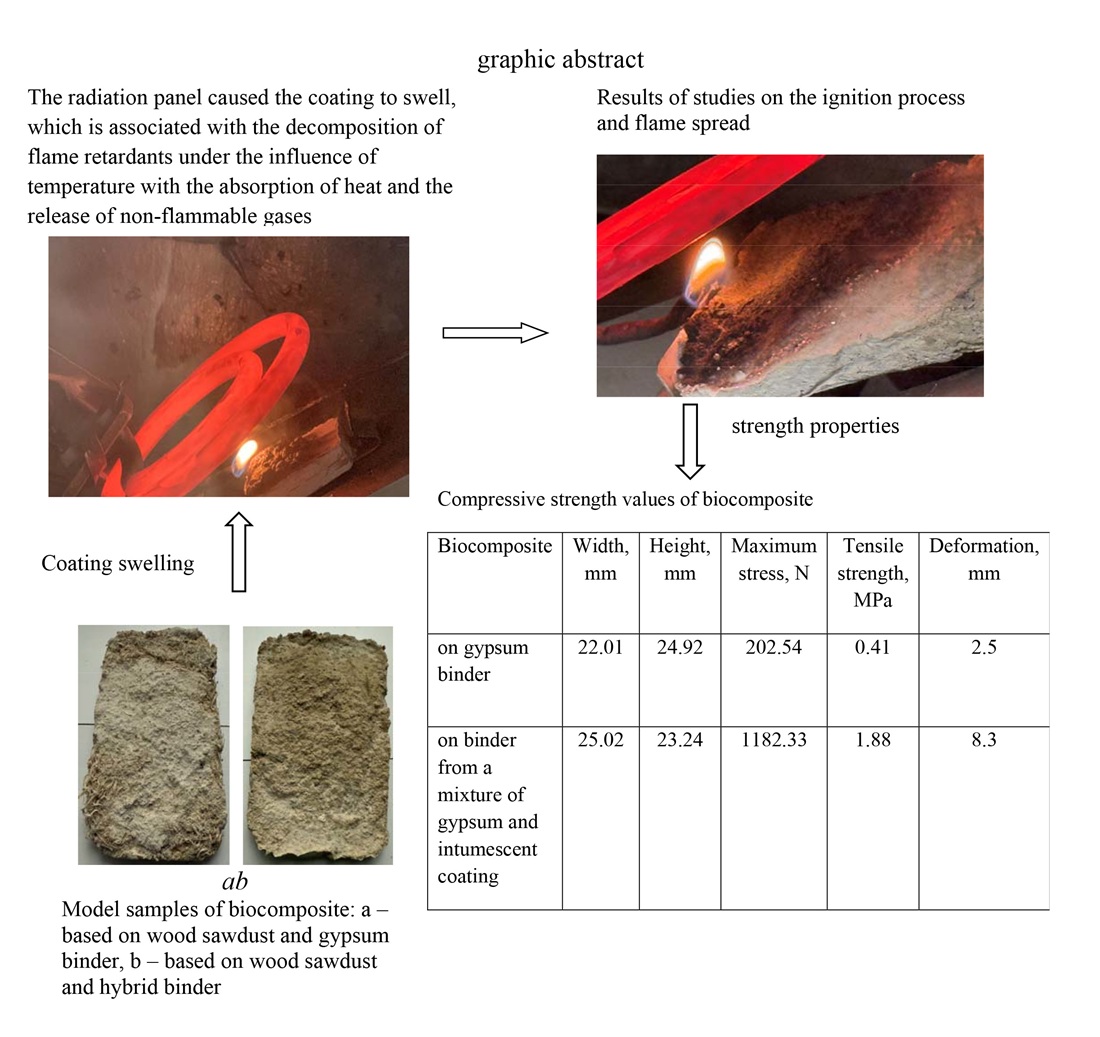

The process that forms the properties of fire-resistant biocomposites based on wood sawdust and a binder from a mixture of gypsum and an intumescent coating based on PVA dispersion has been investigated. The task addressed is to ensure the stability of biocomposites based on a gypsum binder to changes under operating conditions. This is important since the production of biocomposites from renewable sources for construction is relevant.

It has been proven that when thermally exposed to the biocomposite samples, no ignition occurred, the maximum temperature of the flue gases was about 84°C. When using a gypsum binder, a non-combustible structure was formed on the surface of the biocomposite, which prevented the sample from igniting. For a biocomposite based on a binder from a mixture of gypsum and an intumescent coating based on PVA dispersion (hybrid binder), charring of the sample surface is characteristic, which prevents its ignition.

In addition, the results of determining the process of wetting biocomposites with test liquids showed that the obtained solids belong to hydrophilic materials with high water wettability. Analysis of the results of experiments on water absorption of biocomposites reveals that the maximum mass gain of the biocomposite on gypsum binder under the influence of moisture was almost 27% and the main increase in moisture occurred in the first 5 days of exposure. The mass gain of the biocomposite samples on hybrid binder was less than 10% due to the formation of a shell on the surface of sawdust. The value of the compressive strength of biocomposites showed that the sample formed on gypsum binder is significantly fragile. However, for the biocomposite formed on hybrid binder, the ultimate strength is 1.88 MPa, which is provided by the adhesive properties of the intumescent coating.

Thus, there are grounds to argue about the possibility to effectively design operationally stable biocomposites for construction

References

- Ansari, K. H., Routroy, S., Samyal, R., Kaushik, S. (2025). Development and optimization of pearl millet waste biocomposite ceiling tiles: a waste management approach. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-08351-1

- Selvaraj, V. K., Subramanian, J., Dutt, S. S., Annamalai, K., Natarajan, E., Kumaresan, S. (2025). A comparative study on acoustical properties using waste recycled porous materials for environmental sustainability. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-10065-3

- Sanadi, A. R., Guna, V., Hoysal, R. V., Krishna, A., Deepika, S., Mohan, C. B., Reddy, N. (2023). MAPP Compatibilized Recycled Woodchips Reinforced Polypropylene Composites with Exceptionally High Strength and Stability. Waste and Biomass Valorization, 15 (1), 301–312. https://doi.org/10.1007/s12649-023-02150-3

- Betené, A. D. O., Batoum, C. S., Ndoumou Belinga, R. L., Betené Ebanda, F., Tamba, J. G., Atangana, A. et al. (2023). Extraction and characterization of a novel tropical fibre Megaphrynium macrostachyum as a biosourced reinforcement for gypsum-based biocomposites. Journal of Composite Materials, 57 (16), 2543–2562. https://doi.org/10.1177/00219983231174682

- Bumanis, G., Irbe, I., Sinka, M., Bajare, D. (2021). Biodeterioration of Sustainable Hemp Shive Biocomposite Based on Gypsum and Phosphogypsum. Journal of Natural Fibers, 19 (15), 10550–10563. https://doi.org/10.1080/15440478.2021.1997871

- Sinka, M., Zorica, J., Bajare, D., Sahmenko, G., Korjakins, A. (2020). Fast Setting Binders for Application in 3D Printing of Bio-Based Building Materials. Sustainability, 12 (21), 8838. https://doi.org/10.3390/su12218838

- Jha, K., Degala, S. K., Yadav, A. S. (2020). Characterization of Hemp Fibre-Reinforced Gypsum Panels for Building Insulation. Advances in Materials Processing, 91–100. https://doi.org/10.1007/978-981-15-4748-5_9

- Chikhi, M., Agoudjil, B., Boudenne, A., Gherabli, A. (2013). Experimental investigation of new biocomposite with low cost for thermal insulation. Energy and Buildings, 66, 267–273. https://doi.org/10.1016/j.enbuild.2013.07.019

- Bumanis, G., Andzs, M., Sinka, M., Bajare, D. (2023). Fire Resistance of Phosphogypsum- and Hemp-Based Bio-Aggregate Composite with Variable Amount of Binder. Journal of Composites Science, 7 (3), 118. https://doi.org/10.3390/jcs7030118

- Bumanis, G., Vitola, L., Pundiene, I., Sinka, M., Bajare, D. (2020). Gypsum, Geopolymers, and Starch – Alternative Binders for Bio-Based Building Materials: A Review and Life-Cycle Assessment. Sustainability, 12 (14), 5666. https://doi.org/10.3390/su12145666

- Yang, C.-Y., Chiang, C.-L., Kuan, C.-F., Kuan, H.-C., Chang, T.-C. (2025). Sustainable flame retardant design for biodegradable polybutylene succinate using tea residue-derived additives. Polymer, 339, 129105. https://doi.org/10.1016/j.polymer.2025.129105

- Yan, Y., Dong, S., Jiang, H., Hou, B., Wang, Z., Jin, C. (2022). Efficient and Durable Flame-Retardant Coatings on Wood Fabricated by Chitosan, Graphene Oxide, and Ammonium Polyphosphate Ternary Complexes via a Layer-by-Layer Self-Assembly Approach. ACS Omega, 7 (33), 29369–29379. https://doi.org/10.1021/acsomega.2c03624

- Tsapko, Y., Tsapko, А. (2018). Establishment of fire protective effectiveness of reed treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 4 (10 (94)), 62–68. https://doi.org/10.15587/1729-4061.2018.141030

- Song, K., Lee, J., Choi, S.-O., Kim, J. (2019). Interaction of Surface Energy Components between Solid and Liquid on Wettability, and Its Application to Textile Anti-Wetting Finish. Polymers, 11 (3), 498. https://doi.org/10.3390/polym11030498

- Mańkowski, P., Laskowska, A. (2021). Compressive strength parallel to grain of earlywood and latewood of yellow pine. Maderas. Ciencia y Tecnología, 23. https://doi.org/10.4067/s0718-221x2021000100457

- Tsapko, Y., Tsapko, А., Bondarenko, O. (2020). Modeling the process of moisture diffusion by a flame-retardant coating for wood. Eastern-European Journal of Enterprise Technologies, 1 (10 (103)), 14–19. https://doi.org/10.15587/1729-4061.2020.192687

- Tsapko, Y. V., Yu Tsapko, A., Bondarenko, O. P., Sukhanevych, M. V., Kobryn, M. V. (2019). Research of the process of spread of fire on beams of wood of fire-protected intumescent coatings. IOP Conference Series: Materials Science and Engineering, 708 (1), 012112. https://doi.org/10.1088/1757-899x/708/1/012112

- Tsapko, Y., Tsapko, A., Lomaha, V., Illiuchenko, P., Berdnyk, O., Likhnyovskyi, R. et al. (2025). Establishing patterns in the formation of biocomposites for thermal insulation of building structures. Eastern-European Journal of Enterprise Technologies, 4 (10 (136)), 56–64. https://doi.org/10.15587/1729-4061.2025.337401

- Tsapko, Y., Tsapko, A., Likhnyovskyi, R., Berdnyk, O., Sukhanevych, M., Slutska, O., Borysova, A. et al. (2025). Establishing the thermal changes in the foam layer of a biocomposite coating upon the addition of potassium nitrate. Eastern-European Journal of Enterprise Technologies, 5 (10 (137)), 67–76. https://doi.org/10.15587/1729-4061.2025.341605

- Tsapko, Y., Likhnyovskyi, R., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K. et al. (2022). Identifying parameters for wood protection against water absorption. Eastern-European Journal of Enterprise Technologies, 6 (10 (120)), 71–81. https://doi.org/10.15587/1729-4061.2022.268286

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Аleksii Tsapko, Oksana Berdnyk, Ruslan Likhnyovskyi, Vladyslav Halitsa, Maryna Sukhanevych, Ruslan Klymas, Vitally Prisyazhnuk, Pavlo Illiuchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.