Визначення впливу параметрів барабанного змішувача на зміну концентрації компонентів тіста під час початкової стадії змішування

DOI:

https://doi.org/10.15587/1729-4061.2025.327160Ключові слова:

параметри машини, дозування компонентів, процес змішування, структуроутворення суміші, перша стадіяАнотація

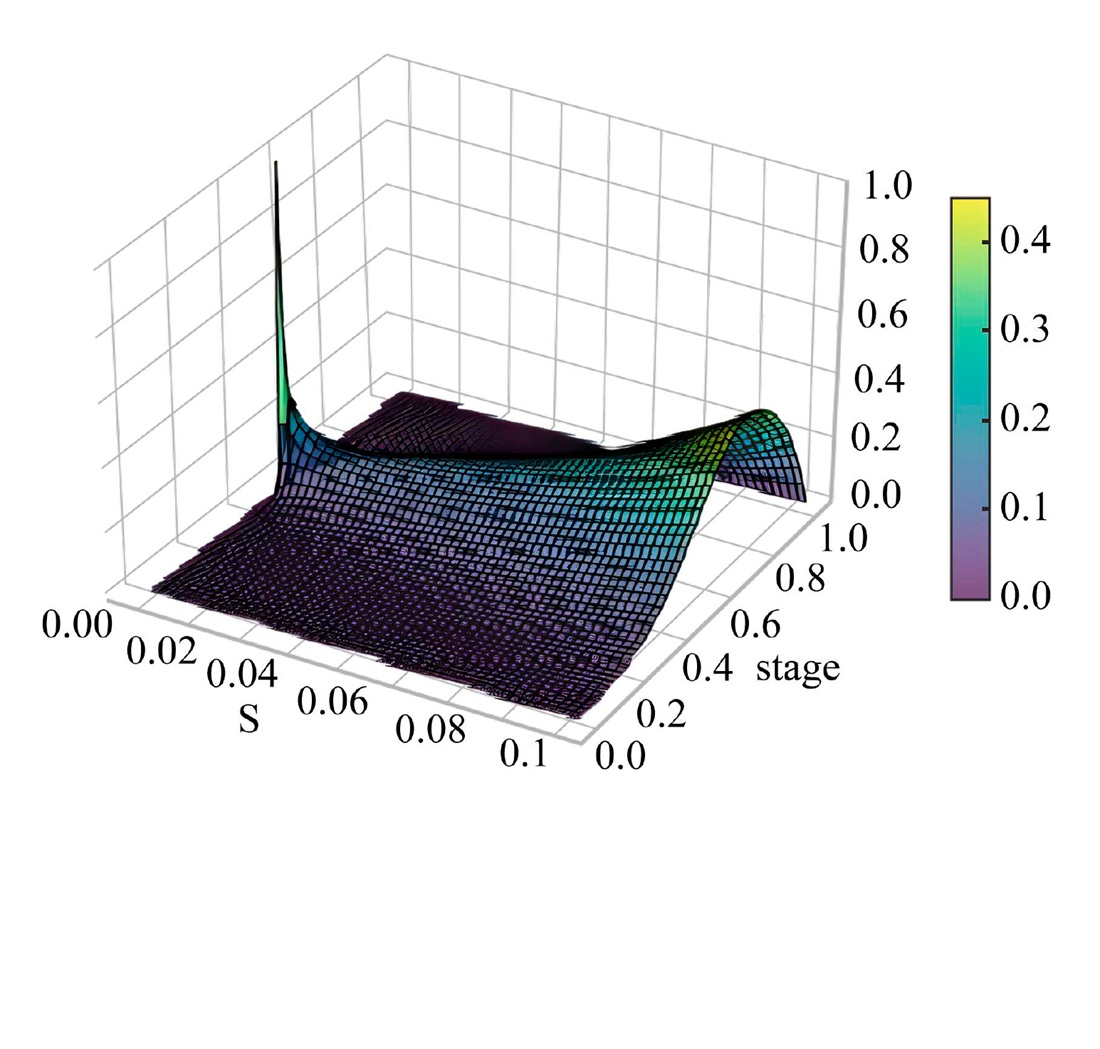

Об’єктом дослідження є процес змішування компонентів борошна та рідкої фази у змішувачі. Проблематика дослідження полягає в аналізі особливостей технологічного процесу змішування тіста та встановленні закономірностей рівномірного розподілу компонентів на основі теоретичних і експериментальних досліджень фізико-механічних, колоїдних та біохімічних процесів. Запропоновано математичні моделі та концептуальні підходи для моделювання переносу компонентів борошна та рідини під час змішування тіста. Розглянуто концептуальне представлення удосконаленої моделі першої стадії замішування тіста з урахуванням впливу конструктивних параметрів барабанного робочого органу та багатогранної робочої камери змішувача і технологічних режимів. При цьому розроблено модифіковане рівняння для чисельного моделювання процесу початкового етапу змішування. Це дозволяє ефективно обчислювати просторові змінні та здійснювати попереднє прогнозування динаміки процесу.

Встановлено, що тривалість взаємодії компонентів до утворення рідинно-в’язкої структури становить 60–65 секунд. На цьому етапі стадії важливо забезпечити високу інтенсивність змішування для досягнення швидкого та рівномірного розподілу компонентів, щоб забезпечити необхідну якість суміші.

Особливістю отриманих результатів є визначення часових та просторових параметрів процесу, а також встановлення принципових закономірностей перебігу стадії попереднього змішування. Запропоновані підходи можуть бути використані на етапах конструкторських розрахунків для оцінювання ефективності змішувачів та вибору їх раціональних параметрів, що сприятиме підвищенню продуктивності і якості готової продукції

Посилання

- Stadnyk, I., Vitenko, T., Droździel, P., Derkach, A. (2016). Simulation of components mixing in order to determine working bodies rational parameters. Advances in Science and Technology Research Journal, 10 (31), 130–138. https://doi.org/10.12913/22998624/64068

- Stadnyk, I. Ya. (2013). Naukovo-tekhnichni osnovy protsesiv ta rozrobka obladnannia dlia bezlopatevoho zmishuvannia tista. Kyiv, 40. Available at: https://dspace.nuft.edu.ua/server/api/core/bitstreams/e94e209e-680e-4929-a314-3ccb15ec7f5f/content

- Volkov, M. V. (2014). Metod rascheta processa smeshivaniya sypuchih materialov v novom apparate s otkrytoy rabochey kameroy. Yaroslavl'.

- Shpak, V. (2015). Modeliuvannia zamisu tista ta vyznachennia ratsionalnykh parametriv robochykh orhaniv tistomisylnykh mashyn. Kyiv: NUKhT, 22.

- Gvozdev, V. O. (2008). Substantiation of technological process and design parameters of high-speed screw feed mixer. Glevakha, 193.

- Piddubnyi, V. А., Pankiv, Yu. V., Stadnyk, I. Ya., Petrychenko, Ye. A. (2021). Integrated solutions and instrument design of transitional processes of component mixing in pseudospace. Food Production Equipment and Technologies, 42 (1), 82–90. Available at: https://oblad.donnuet.edu.ua/index.php/tehnolog/article/view/144

- Drahuzia, O., Zubriy, O. (2018). Selection of the mixer type for the production of liquid detergents. International scientific journal "Internauka", 19 (1), 24–27. Available at: https://www.inter-nauka.com/uploads/public/15423566603541.pdf

- Stadnyk, I., Piddubnyi, V., Chahaida, A., Fedoriv, V., Hushtan, T., Kraievska, S. et al. (2023). Energy Saving Thermal Systems on the Mobile Platform of the Mini-Bakery. Strojnícky Časopis - Journal of Mechanical Engineering, 73 (1), 169–186. https://doi.org/10.2478/scjme-2023-0014

- Dolomakin, Y. (2016.) Determination of the main stages of mixing wheat sourdough relative method. Journal of food and packaging science, Technique and Technologies, 9, 49–54. Available at: https://dspace.nuft.edu.ua/server/api/core/bitstreams/9cb5730f-8112-4ac2-b903-d4c75388f4dd/content

- Stadnyk, I., Piddubnyi, V., Khareba, L., Fedoriv, V., Pidhornyi, V. (2021). Suchasni tekhnolohiyi ta enerhetychni potoky pry formuvanni boroshnianykh napivfabrykativ. Ternopil, 372. Available at: https://elartu.tntu.edu.ua/handle/lib/35163

- Derkach, A., Kravcheniuk, R., Stadnyk, I., Radchenko, Y., Piddubnyi, V. (2024). Influence of mixer parameters on the homogeneity of the resulting mixture when mixing components in the bakery industry. Technical Engineering, 1 (93), 52–57. https://doi.org/10.26642/ten-2024-1(93)-52-57

- Vodyanitsky, G., Slyusarenko, I., Tymkiv, V. (2018). Justification of the parameters and modes of operation of the feeder mixer shredder method of modeling. Scientific Horizons, 7 3(12), 57–66. https://doi.org/10.33249/2663-2144-2018-73-12-57-66

- Volontyr, L. O., Zelinska, O. V., Potapova, N. A., Chikov, I. A. (2020). Chyselni metody. Vinnytsia: VNAU, 322. Available at: http://repository.vsau.org/card.php?lang=uk&id=27703

- Dereza, O., Dereza, S. (2014). Analysis of methods of design of process of mixing of forage. Naukovyi visnyk Tavriyskoho derzhavnoho ahrotekhnolohichnoho universytetu, 1 (4), 95–100. Available at: http://elar.tsatu.edu.ua/handle/123456789/1787

- Stadnyk, I., Pankiv, Y., Vasyliv, V., Kos, T. (2020). Dynamics of inter-phase interaction of components during mixing. Food Resources, 8 (15), 174–184. https://doi.org/10.31073/foodresources2020-15-19

- Drobot, V. I. (2019). Dovidnyk z tekhnolohiyi khlibopekarskoho vyrobnytstva. Kyiv, 580.

- Stadnyk, P. D., Dobrotvor, I. G., Szwedziak, K. (2016). Determination of Power Output and Impact on the Rheological Parameters of Raw Materials during Rolling. Agricultural Engineering, 20 (2), 5–12. https://doi.org/10.1515/agriceng-2016-0035

- Stefan, E. V., Miznik, L. M. (2005). Mathematical modeling of coextrusion processes in the manufacture of tubular products with fillings. Science NUHT News, 6 (44), 82–85.

- Stadnyk, I., Piddubnyi, V., Mykhailyshyn, R., Petrychenko, I., Fedoriv, V., Kaspruk, V. (2022). The Influence of Rheology and Design of Modeling Rolls On the Flow and Specific Gravity During Dough Rolling and Injection. Journal of Advanced Manufacturing Systems, 22 (02), 403–421. https://doi.org/10.1142/s0219686723500208

- Liaposhchenko, O. O., Ivanov, V. O., Pavlenko, I. V., Demianenko, М. М., Starynskyi, О. Ye., Kovtun, V. V. (2018). Optimizing phase separation equipment packaging with using of modular separation devices. Scientific Works. https://doi.org/10.15673/swonaft.v82i1.1018

- Dolomakin, Yu. Yu., Babanov, I. V., Zhitnetskyi, I. G. (2016). The duration of the main stages of preparation of liquid foam, determined by the indirect method. Collection of scientific works of KhDUHT, 1 (23), 201–211.

- Pavlenko, I. V., Yukhymenko, M. P., Lytvynenko, A. V., Bocko, J. (2019). Solving the Nonstationary Problem of the Disperse Phase Concentration during the Pneumoclassification Process of Mechanical Mixtures. Journal of Engineering Sciences, 6 (1), f1–f5. https://doi.org/10.21272/jes.2019.6(1).f1

- Lebovka, N., Petryk, M., Vorobiev, E. (2022). Monte Carlo simulation of dead-end diafiltration of bidispersed particle suspensions. Physical Review E, 106 (6). https://doi.org/10.1103/physreve.106.064610

- Suvolapov, V., Novitskiy, A., Khmelevski, V., Bustruy, O. (2020). Investigation of the Heat Transfer Process in Internal Combustion Engine Cylinders. Central Ukrainian Scientific Bulletin. Technical Sciences, 3 (34), 266–274. https://doi.org/10.32515/2664-262x.2020.3(34).266-274

- Michalak, M., Ochowiak, M., Pavlenko, I., Włodarczak, S., Krupińska, A. (2019). Bubble-vortex spraying of liquid with static mixing. Poznań, 87–98.

- Lebovka, N., Cieśla, M., Petryk, M., Vygornitskii, N. (2024). Cooperative sequential adsorption of monomers on a square lattice in the presence of repulsive interactions between near neighbors. Physical Review E, 110 (6). https://doi.org/10.1103/physreve.110.064801

- Derkach, A., Stadnyk, I., Piddubnyi, V., Chahaida, A., Radchenko, I. (2024). Achievements and problems in studying the mechanism of thermal potential transfer regulation between liquids. Machinery & Energetics, 15 (1), 104–117. https://doi.org/10.31548/machinery/1.2024.104

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Igor Stadnyk, Volodymyr Piddubnyi, Olena Kolomiiets, Andrii Chahaida, Oleh Kravets, Viktor Fedoriv, Olena Ieremeieva, Vitalii Mihailik, Rostyslav Kravcheniuk, Iurii Radchenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.