Research of the performance indicators of printing impressions on cardboard for packaging production

DOI:

https://doi.org/10.15587/1729-4061.2025.338268Keywords:

offset impressions, low-migration paints, deformation properties, cardboard structure, electron microscopy, packaging strengthAbstract

In modern packaging production, a diverse range of cardboards is used. Therefore, the current problem is the choice of cardboards to ensure the functional purpose of packaging. The object of the study was printing impressions for the production of cardboard packaging.

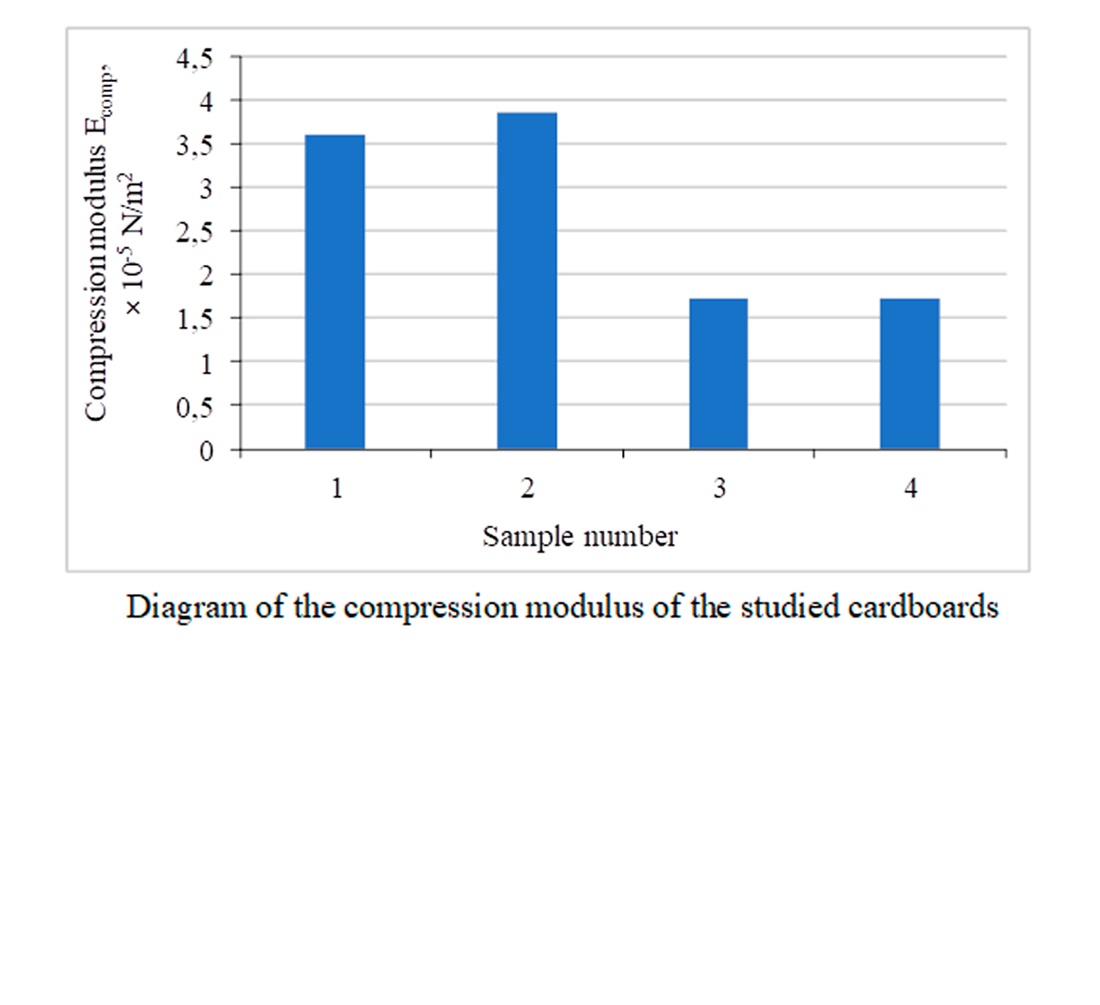

Methods for studying the operational properties of cardboards that arise during the use of packaging are proposed. Based on the conducted electron microscopic studies, the influence of the structural structure of cardboards on the mechanical and physicochemical properties of printing impressions has been confirmed. The presence of waste paper and mechanical pulp in the cardboard structure increases the water absorption rate of the printing impression. The value of the relative tensile deformation of cardboard in the transverse and longitudinal directions has been determined. It has been found that with an increase in the tensile value, the ability of packaging to compensate for mechanical loads without destruction increases. The maximum anisotropy coefficient and compression modulus of cardboard impressions have been calculated. When ensuring the safety of packaged products, problems arise related to the appearance of solvent migration from printed images on packages. Chromatographic studies have confirmed that with an increase in the number of coated layers on the surface of offset impressions, the migration of paint solvents to the contents of the packages decreases. This allows the selection of cardboard for the manufacture of packages taking into account their structural structure. The results obtained make it possible to improve the technological process of manufacturing cardboard packages, ensuring their environmental friendliness and consumer properties according to their functional purpose

References

- Kawecka, A., Cholewa-Wójcik, A. (2017). Jakość opakowania jako determinanta bezpieczeństwa żywności w kontekście wymagań społecznych konsumentów. Zywnosc Nauka Technologia Jakosc/Food Science Technology Quality, 112 (3), 138–148. https://doi.org/10.15193/zntj/2017/112/205

- Analiz rynku pakuvalnoi produktsiyi v Ukraini. Available at: https://inventure.com.ua/uk/analytics/investments/analiz-rinku-pakuvalnoyi-produkciyi-v-ukrayini

- The Future of Global Packaging to 2028. Available at: https://www.smithers.com/services/market-reports/packaging/the-future-of-global-packaging-to-2028

- Banterle, A., Cavaliere, A., Claire Ricci, E. (2012). Food Labelled Information: An Empirical Analysis of Consumer Preferences. International Journal on Food System Dynamics, 3 (2), 156–170. https://doi.org/10.18461/ijfsd.v3i2.325

- Doslidzhennia: molod nadaie perevahu ekolohichniy upakovtsi. Available at: https://logist.fm/news/doslidzhennya-molod-nadaie-perevagu-ekologichniy-upakovci

- Herbes, C., Beuthner, C., Ramme, I. (2018). Consumer attitudes towards biobased packaging – A cross-cultural comparative study. Journal of Cleaner Production, 194, 203–218. https://doi.org/10.1016/j.jclepro.2018.05.106

- Johnson, C., Brown, E. (2019). Analysis of Cardboard Packaging Processing Techniques for Food Products. Food Packaging Technology, 5 (3), 210–225.

- Barber, N. (2010). “Green” wine packaging: targeting environmental consumers. International Journal of Wine Business Research, 22 (4), 423–444. https://doi.org/10.1108/17511061011092447

- Park, J., Park, M., Choi, D. S., Jung, H. M., Hwang, S. W. (2020). Finite Element-Based Simulation for Edgewise Compression Behavior of Corrugated Paperboard for Packaging of Agricultural Products. Applied Sciences, 10 (19), 6716. https://doi.org/10.3390/app10196716

- Hanssen, O. J., Vold, M., Schakenda, V., Tufte, P.-A., Møller, H., Olsen, N. V., Skaret, J. (2017). Environmental profile, packaging intensity and food waste generation for three types of dinner meals. Journal of Cleaner Production, 142, 395–402. https://doi.org/10.1016/j.jclepro.2015.12.012

- Valdec, D., Miljković, P., Auguštin, B. (2017). The influence of printing substrate properties on color characterization in flexography according to the ISO specifications. Tehnički glasnik, 11 (3), 73–77. Available at: https://hrcak.srce.hr/file/275270

- Low Migration Inks Market by Process (Gravure, Flexography, Off-Set, Digital), End-Use Industry (Food & Beverages, Pharmaceutical, Cosmetics), and Region (North America, Asia Pacific, Europe, Rest of the World) - Global Forecast to 2022. Available at: https://www.marketsandmarkets.com/Market-Reports/low-migration-ink-market-63935492.html

- Havenko, S. F., Ohirko, M. O. (2018). Vplyv struktury pakuvalnykh kartoniv na protses vzaiemodiyi z drukarskoiu farboiu ta mozhlyvu mihratsiyu yii skladovykh do upakovanykh produktiv. Suchasne reprodukuvannia: inzhynirynh, modeliuvannia, multy- ta krosmediini tekhnolohiyi: materialy naukovo-praktychnoho seminaru. Kyiv: KPI im. Ihoria Sikorskoho, 34–37. Available at: https://ela.kpi.ua/items/b56e07fe-966d-4115-a8f0-da0b6a35dd83

- Havenko, S. F., Holovatska, N. V. (2010). Pat. No. 58827 UA. Zatysknyi mekhanizm dlia vyznachennia oporu prodavliuvannia kartonu i hofrokartonu. declareted: 07.10. 2010; published: 26.04.2011.

- Lenyuk, G. K. (2017). The determination of linear correlation of board crushing resistance and its tear resistance in cross machine direction. Ukrainian Metrological Journal, 4, 65–68. https://doi.org/10.24027/2306-7039.4.2017.125520

- Alaska Plus. Available at: https://www.icsfirpo.it/wp-content/uploads/2017/02/4-scheda-tecnica-alaska-plus.pdf

- Alaska Strong. Available at: https://schramm-co.com/wp-content/uploads/2023/10/Alaska-Strong.pdf

- Multicolor Spezial. Available at: https://www.gepkagit.com.tr/img/pdfs/karton/mm/MCS-Multicolor-Spezial.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Svitlana Havenko, Ivanna Koniukhova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.