Determining the effect of heat treatment on the indicators of demineralized whey liquid concentrates

DOI:

https://doi.org/10.15587/1729-4061.2025.347224Keywords:

whey, heat treatment, water activity, surface tension, effective viscosity, thixotropy of the system, quality indicators, amino acid compositionAbstract

This study investigates the technology of liquid demineralized whey concentrates. The task addressed is to determine rational modes for the thermal treatment of liquid demineralized whey concentrates in order to improve their functional and technological properties.

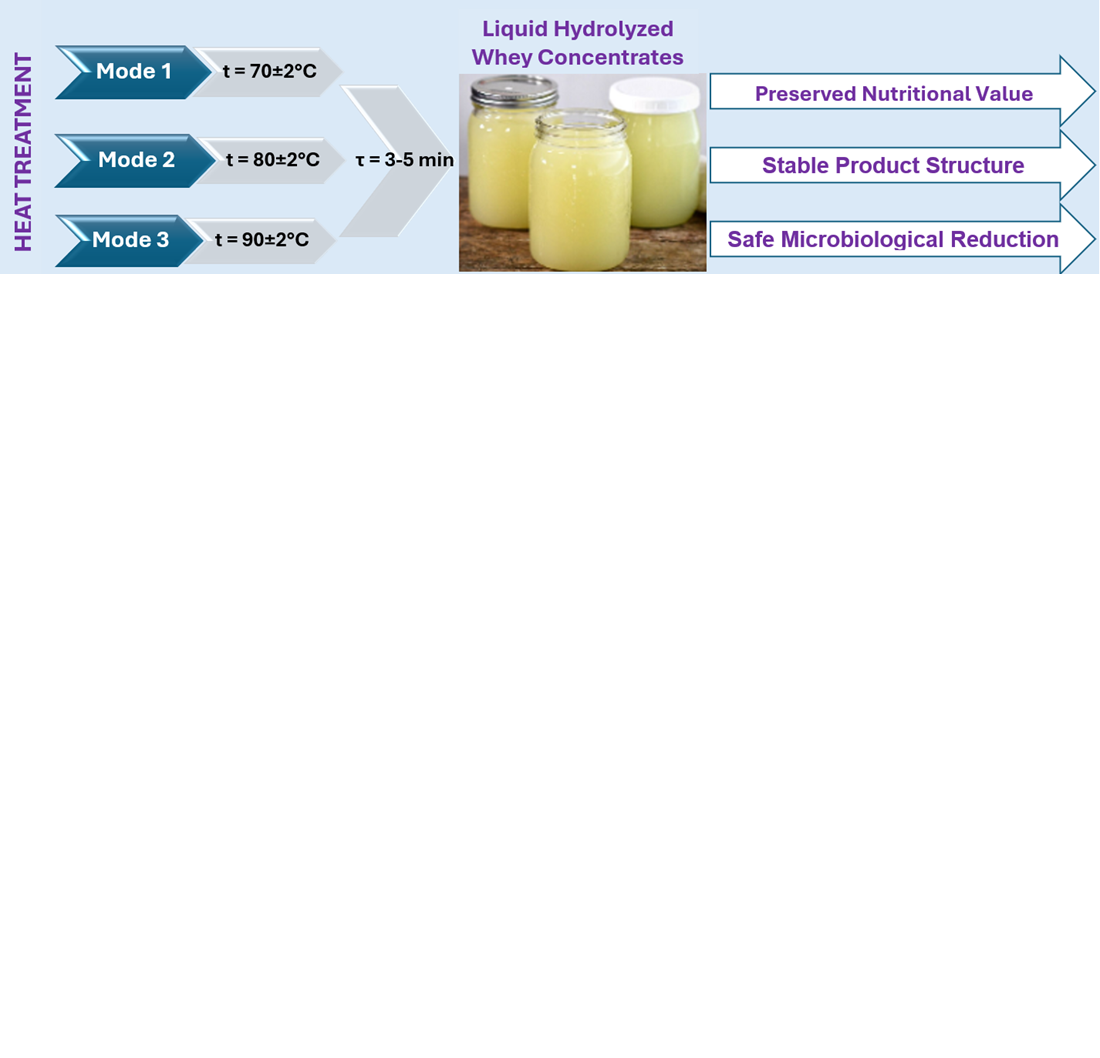

Liquid whey concentrates were pasteurized under the following modes: 1 (temperature – 70 ± 2°C, duration – 3–5 min), 2 (temperature – 80 ± 2°C, duration – 3–5 min), 3 (temperature – 90 ± 2°C, duration – 3–5 min).

With an increase in the dry matter content from 10 to 40% in the concentrates, the density increased, the water activity and surface tension decreased, and the active acidity stabilized. The choice of mode 2 of heat treatment for a concentrate with a mass fraction of dry matter of 40% turned out to be the most rational since it provided a balance between high pasteurization efficiency and preservation of the qualitative characteristics of the studied sample.

With increasing concentration of dry matter, a significant increase in effective viscosity was observed. For 40% concentrate, mode 2 provides the maximum level of thixotropy – up to 75%, which indicates significant elasticity and technological stability of the product.

Analyzing the amino acid composition of 40% concentrate under different pasteurization modes, a clear trend of decreasing the content of all amino acids with increasing heat treatment temperature was observed.

The results could be used as recommendations for adjusting technological parameters to obtain stable whey concentrates. The pasteurized concentrates obtained are semi-finished products that could be used in the food industry

References

- Mykhalevych, A., Buniowska-Olejnik, M., Polishchuk, G., Puchalski, C., Kamińska-Dwórznicka, A., Berthold-Pluta, A. (2024). The Influence of Whey Protein Isolate on the Quality Indicators of Acidophilic Ice Cream Based on Liquid Concentrates of Demineralized Whey. Foods, 13 (1), 170. https://doi.org/10.3390/foods13010170

- Kheto, A., Adhikary, U., Dhua, S., Sarkar, A., Kumar, Y., Vashishth, R. et al. (2024). A review on advancements in emerging processing of whey protein: Enhancing functional and nutritional properties for functional food applications. Food Safety and Health, 3 (1), 23–45. https://doi.org/10.1002/fsh3.12067

- Saputra, A., Gavahian, M., Purnomo, E. H., Saraswati, S., Hasanah, U., Boing Sitanggang, A. (2025). High-pressure processing as an emerging technology for enhancing dairy product safety and quality: a critical review of latest advances, sustainability impact, limitations, and prospects. Critical Reviews in Food Science and Nutrition, 65 (33), 8341–8365. https://doi.org/10.1080/10408398.2025.2499623

- Rabbani, A., Ayyash, M., D’Costa, C. D. C., Chen, G., Xu, Y., Kamal-Eldin, A. (2025). Effect of Heat Pasteurization and Sterilization on Milk Safety, Composition, Sensory Properties, and Nutritional Quality. Foods, 14 (8), 1342. https://doi.org/10.3390/foods14081342

- Qi, P. X., Ren, D., Xiao, Y., Tomasula, P. M. (2015). Effect of homogenization and pasteurization on the structure and stability of whey protein in milk. Journal of Dairy Science, 98 (5), 2884–2897. https://doi.org/10.3168/jds.2014-8920

- Wada, Y., Lönnerdal, B. (2014). Effects of Different Industrial Heating Processes of Milk on Site-Specific Protein Modifications and Their Relationship to in Vitro and in Vivo Digestibility. Journal of Agricultural and Food Chemistry, 62 (18), 4175–4185. https://doi.org/10.1021/jf501617s

- Freire, P., Zambrano, A., Zamora, A., Castillo, M. (2022). Thermal Denaturation of Milk Whey Proteins: A Comprehensive Review on Rapid Quantification Methods Being Studied, Developed and Implemented. Dairy, 3 (3), 500–512. https://doi.org/10.3390/dairy3030036

- Fitzsimons, S. M., Mulvihill, D. M., Morris, E. R. (2007). Denaturation and aggregation processes in thermal gelation of whey proteins resolved by differential scanning calorimetry. Food Hydrocolloids, 21 (4), 638–644. https://doi.org/10.1016/j.foodhyd.2006.07.007

- Singh, H., Roberts, M. S., Munro, P. A., Teo, C. T. (1996). Acid-Induced Dissociation of Casein Micelles in Milk: Effects of Heat Treatment. Journal of Dairy Science, 79 (8), 1340–1346. https://doi.org/10.3168/jds.s0022-0302(96)76490-1

- Li, H., Zhao, T., Li, H., Yu, J. (2021). Effect of Heat Treatment on the Property, Structure, and Aggregation of Skim Milk Proteins. Frontiers in Nutrition, 8. https://doi.org/10.3389/fnut.2021.714869

- Qian, F., Sun, J., Cao, D., Tuo, Y., Jiang, S., Mu, G. (2017). Experimental and Modelling Study of the Denaturation of Milk Protein by Heat Treatment. Korean Journal for Food Science of Animal Resources, 37 (1), 44–51. https://doi.org/10.5851/kosfa.2017.37.1.44

- Čurlej, J., Zajác, P., Čapla, J., Golian, J., Benešová, L., Partika, A. et al. (2022). The Effect of Heat Treatment on Cow’s Milk Protein Profiles. Foods, 11(7), 1023. https://doi.org/10.3390/foods11071023

- Haas, J., Kim, B. J., Atamer, Z., Wu, C., Dallas, D. C. (2025). Effects of high-temperature, short-time pasteurization on milk and whey during commercial whey protein concentrate production. Journal of Dairy Science, 108 (1), 257–271. https://doi.org/10.3168/jds.2024-25493

- Bogahawaththa, D., Vasiljevic, T. (2020). Denaturation of selected bioactive whey proteins during pasteurization and their ability to modulate milk immunogenicity. Journal of Dairy Research, 87 (4), 484–487. https://doi.org/10.1017/s0022029920000989

- Mykhalevych, A., Polishchuk, G., Bandura, U., Osmak, T., Bass, O. (2024). Determining the influence of plant-based proteins on the characteristics of dairy ice cream. Eastern-European Journal of Enterprise Technologies, 4 (11 (130)), 6–15. https://doi.org/10.15587/1729-4061.2024.308635

- Polishchuk, G., Sharakhmatova, T., Shevchenko, I., Manduk, O., Mykhalevych, A., Pukhlyak, A. (2023). Scientific substantiation of cream heating duration in the technology of sour cream, enriched with protein. Food Science and Technology, 17 (3). https://doi.org/10.15673/fst.v17i3.2657

- Mykhalevych, A., Moiseyeva, L., Polishchuk, G., Bandura, U. (2024). Determining patterns of lactose hydrolysis in liquid concentrates of demineralized whey. Eastern-European Journal of Enterprise Technologies, 6 (11 (132)), 24–32. https://doi.org/10.15587/1729-4061.2024.318337

- Bobel, I., Adamczyk, G., Falendysh, N. (2022). Nutritional and biological value of mushroom snacks. Food and Environment Safety Journal, 21 (2). https://doi.org/10.4316/fens.2022.018

- Tunick, M. H., Thomas-Gahring, A., Van Hekken, D. L., Iandola, S. K., Singh, M., Qi, P. X. et al. (2016). Physical and chemical changes in whey protein concentrate stored at elevated temperature and humidity. Journal of Dairy Science, 99 (3), 2372–2383. https://doi.org/10.3168/jds.2015-10256

- Ayyash, M., Ali, A. H., Al-Nabulsi, A., Osaili, T., Bamigbade, G., Subash, A. et al. (2025). Effect of acid whey protein concentrate on the rheological properties, antioxidant capacities, and biological activities of bioaccessible fractions in fermented camel milk. Journal of Dairy Science, 108 (2), 1242–1260. https://doi.org/10.3168/jds.2024-25479

- Kusio, K., Szafrańska, J. O., Radzki, W., Sołowiej, B. G. (2020). Effect of Whey Protein Concentrate on Physicochemical, Sensory and Antioxidative Properties of High-Protein Fat-Free Dairy Desserts. Applied Sciences, 10 (20), 7064. https://doi.org/10.3390/app10207064

- Shafiur Rahman, M. (Ed.) (1999). Handbook of Food Preservation. CRC Press.

- Fellows, P. (2000). Food Processing Technology. CRC Press. https://doi.org/10.1201/noe0849308871

- Macdonald, L. E., Brett, J., Kelton, D., Majowicz, S. E., Snedeker, K., Sargeant, J. M. (2011). A Systematic Review and Meta-Analysis of the Effects of Pasteurization on Milk Vitamins, and Evidence for Raw Milk Consumption and Other Health-Related Outcomes. Journal of Food Protection, 74 (11), 1814–1832. https://doi.org/10.4315/0362-028x.jfp-10-269

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Artur Mykhalevych, Galyna Polishchuk, Uliana Bandura, Roman Svyatnenko, Oksana Bass

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.