Вивчення комплексного впливу зовнішніх факторів на ефективність ремонтів полімерними композитними матеріалами

DOI:

https://doi.org/10.31498/2225-6733.49.1.2024.321231Ключові слова:

полімер, відновлення, композит, адгезія, обладнання, мультиметалАнотація

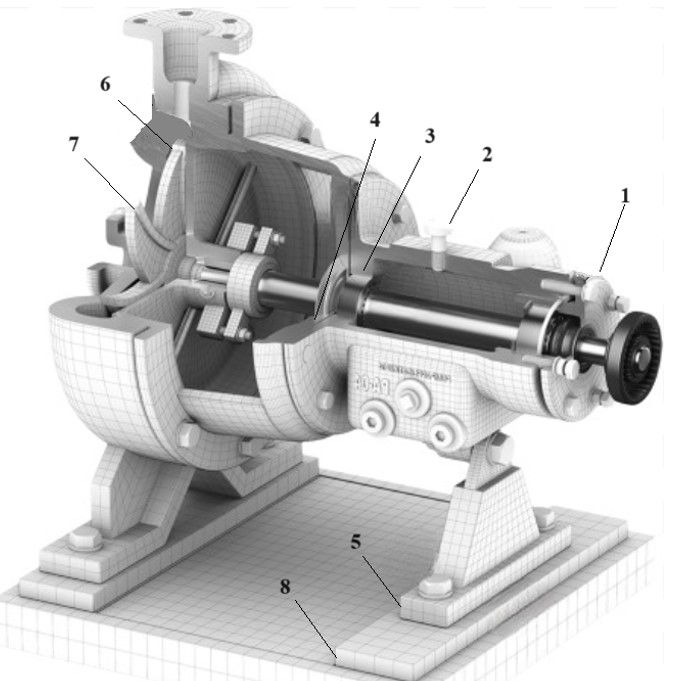

У статті розглядається вплив зовнішніх факторів на ефективність ремонтів полімерними композитними матеріалами. У сучасній важкій промисловості та машинобудуванні застосування композитів набуває дедалі більшої популярності завдяки їхнім численним перевагам, таким як швидке відновлення працездатності обладнання та можливість проведення ремонтних робіт безпосередньо на місці експлуатації. Проте виконання ремонтів у складних умовах, наприклад, при низьких температурах і високій вологості, ставить перед інженерами нові виклики. У статті аналізуються останні дослідження, які показують, що для забезпечення надійності металополімерного з'єднання необхідно дотримуватися певних умов відносної вологості та температури. Встановлено, що найкращі результати адгезійної міцності досягаються після обробки зразків шліфувальним кругом та знежирення поверхні спеціальними очисниками. Дослідження проводилися на зразках композитного матеріалу «мультиметал-сталь 1018», виготовленого фірмою Diamant Metal Plastics GmbH (Germany). Випробування виконувалися на розривній машині РМ20 в лабораторії кафедри МОЗЧМ ДВНЗ «ПДТУ». Основні результати показали, що довговічність обладнання, відремонтованого за допомогою композитів, значною мірою залежить від умов нанесення матеріалу на металеву поверхню. При високій вологості та низькій температурі на поверхневих шарах металу конденсується волога, що призводить до корозійних процесів і зниження адгезійної міцності з'єднання «метал-композит». Для підвищення адгезійної міцності рекомендується використовувати рідкотекучий мультиметал як перший адгезійний шар або підігрівати пастоподібний мультиметал. Додатково розглянуто можливість знежирення поверхонь ацетоном, що є більш доступним, хоча фірмові очисники демонструють кращі результати в умовах тривалого використання. Висновки статті підтверджують необхідність врахування зовнішніх факторів під час проведення ремонтних робіт з використанням полімерних композитів. Подальші дослідження повинні бути спрямовані на вивчення впливу інших зовнішніх факторів, таких як механічні навантаження та хімічна агресія, на властивості композитних матеріалів

Посилання

Madrid M., Turunen J., Seitz W. General industrial adhesive applications: Qualification, specification, quality control, and risk mitigation. Advances in Structural Adhesive Bonding. 2-nd ed. Woodhead Publishing, 2023. Pp. 849-876. DOI: https://doi.org/10.1016/B978-0-323-91214-3.00023-5.

Weir Minerals. Launches New Zero VOC Adhesive Range for Rubber Lining. URL: https://www.global.weir/newsroom/news-articles/weir-minerals-launches-new-zero-voc-adhesive-range-for-rubber-lining/ (дата звернення: 15.05.2024).

Спосіб відновлення опорної поверхні важконавантажених машин: пат. 41759 Україна: МПК B05D3/12. №2001031777; А. О. Іщенко, О. В. Іщенко; заявл. 16.03.01; опубл. 15.02.05, Бюл. № 2. 4 с.

Спосіб відновлення опорної поверхні важконавантажених металургійних машин: пат. 4804 Україна: МКИ ВО5Д3/12. №20040402991; А. О. Іщенко, В. П. Гришко, І. А. Калініченко, І. К. Єфимов; заявл. 22.04.04; опубл. 15.02.05, Бюл. № 2. 4 с.

Визначення можливості використання компаундів фірми «Діамант-адгезив» під час ремонту суднових технічних засобів. Звіт ПІВДЕНДІМФ. Одеса, 1997. 97 с.

Tao R., Alfano M., Lubineau G. Laser-based surface patterning of composite plates for improved secondary adhesive bonding. Composites Part A: Applied Science and Manufacturing. 2018. Vol. 109. Pp. 84-94. DOI: https://doi.org/10.1016/j.compositesa.2018.02.041.

Czarnecki J. V., Wetzel M., Dolderer D., Eisenschink C. The Use of Peel Ply as a Method to Create Reproduceable But Contaminated Surfaces for Structural Adhesive Bonding of Carbon Fiber Reinforced Plastics / J. Holtmannspötter et al. The Journal of Adhesion. 2013. Vol. 89(2). Pp. 96-110. DOI: https://doi.org/10.1080/00218464.2012.731828.

Katnam K. B., Da Silva L. F. M., Young T. M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Progress in Aerospace Sciences. 2013. Vol. 61. Pp. 26-42. DOI: https://doi.org/10.1016/j.paerosci.2013.03.003.

Штекель Л. И. Полимерная «холодная» сварка. Современные методы ремонта судового оборудования с использованием полимерных материалов. Одесса: Студия «Негоциант», 2003. 132 с.

Визначення механічних характеристик ремонтних полімерних матеріалів / Іщенко А. О., Гришко В. П., Єфімов І. К., Молнар Л. Захист металургійних машин від поломок. 2005. Вип. 8. С. 93-98.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.