Дослідження ерозії вогнетривів ковшу при вдуванні газу вглиб ванни крізь обертову фурму

DOI:

https://doi.org/10.31498/2225-6733.49.1.2024.321268Ключові слова:

вогнетрив, газ, гідродинаміка, ерозія, ківш, руйнування, стійкість, футеруванняАнотація

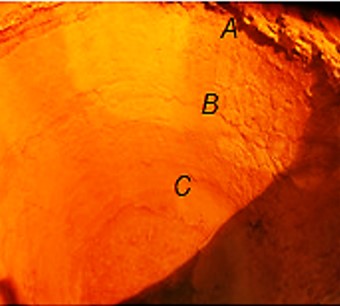

Із застосуванням ізотермічного моделювання отримані нові дані стосовно впливу переміщення газових струменів із сопел наконечника заглибної обертової фурми на гідродинаміку та інтенсивність масообмінних процесів у ковшовій ванні. Досліджені особливості ерозійного зношування робочого шару футерівки великовантажного чавунозаливального ковшу під час десульфурації вдуванням порошкоподібних реагентів крізь сопла Т-подібних наконечників заглибних фурм. На основі результатів порівняльного аналізу профілю зношення робочого шару вогнетривів ковшу при використанні нерухомої та обертової конструкції фурм та чисельного моделювання динаміки зношування визначені раціональні витрати газу-носію та швидкість обертання фурми для мінімізації інтенсивності ерозії футерівки

Посилання

Сульфідна ємність та властивості модифікованих ковшових шлаків / Сігарьов Є.М., Єсь-ков Д.В., Крячко Г.Ю., Матина І.М. Збірник наукових праць Дніпровського державного тех-нічного університету (технічні науки). 2024. До 95 річчя кафедри металургії ім. професора В.І. Логінова Дніпровського державного технічного університету. С. 76-88. DOI: https://doi.org/10.31319/2519-2884.tm.2024.7.

Смирнов А. Н., Жемеров С. Г., Штепан Е. В. Исследование стойкости огнеупорного слоя при продувке металла в сталеразливочном ковше инертным газом. Наукові праці Донецького національного технічного університету. 2011. Вип. 12(177). С. 130-136.

Bennett J. P., Smith J. D. Fundamentals of Refractory Technology. The American Ceramic Society, 2001. 316 p.

Schacht C. A. Refractories Handbook. CRC Press, Taylor & Francis Group, Boca Raton, FL, USA. 2004. 516 p.

Lee W. E., Zhang S. Melt Corrosion of Oxide and Oxide-Carbon refractories. International Materials Reviews. 1999. Vol. 44. Iss. 3. Pр. 77-104. DOI: https://doi.org/10.1179/095066099101528234.

Lee W. E. Theory, Experiment and Practice of Slag Attack on Refractories. Tehran International Conference on Refractories, 4-6 May 2004. Рр. 13-27.

Buhr A. Refractories for Secondary Steelmaking Metallurgy. CN-Refractories. 1999. No. 6(3). Pр. 19-30.

Умови служби футеровки сталерозливних ковшів і вимоги, пропоновані до вогнетривких матеріалів / Плохіх П. А., Вожол М. А., Хавалиць Ю. В., Плохіх A. П. Метал та лиття України. 2021. Том 29. № 3(326). С. 21-25. DOI: https://doi.org/10.15407/steelcast2019.10.064.

Corrosion Mechanism of a Density-Reduced Steel Ladle Lining Containing Porous Spinel-Calcium Aluminate Aggregates / Ch. Wohrmeyer et al. Ceramics. 2020. No. 3. Pp. 155-170. doi: https://doi.org/10.3390/ceramics3010015.

Molchanov L. S., Lantukh O. S., Synehin Y. V. Physical Modeling of Erosion Destruction of Teeming Ladle Lining in the Process of Its Exploitation. Bulletin of Vinnitsa Polytechnic Institute. 2019. No. 1. Рр. 65-71. DOI: https://doi.org/10.31649/1997-9266-2019-142-1-65-71.

Krasnikov K., Lyzhov M., Fatykhova T. Computer Analysis of Influence of Melt Blowing Modes on Ladle Lining Mechanical Erosion. Математичне моделювання. 2023. № 1(48). С. 132-137. DOI: https://doi.org/10.31319/2519-8106.1(48)2023.280789.

Zushu L., Kusuhiro M., Zainan T. Reactions Between MgO-C Refractory, Molten Slag and Metal. ISIJ International. 2000. Vol. 40. Iss. Suppl. Рp. 101-105. DOI: https://doi.org/10.2355/isijinternational.40.Suppl_S101.

Застосування вогнетривких матеріалів для сталерозливного ковша / Стоянов О. М., Нізяєв К. Г., Малій Х. В., Кухар В. В. Вісник Приазовського державного технічного університету. Серія: Технічні науки. 2023. Вип. 46. С. 69-78. DOI: https://doi.org/10.31498/2225-6733.46.2023.288166.

Milan C. Application of Refractory Materials in the BOF Steel Plant in TŘINECKÉ ŽELEZÁRNY. The 7th European Oxygen Steelmaking Conference, Trinec, Czech Republic, September 9-11, 2014.

Охотский В. Б., Зражевский А. Д. Закономерности износа ковшевой футеровки. Результаты исследований. Металлургическая и горнорудная промышленность. 2014. № 3. С. 24-28.

Computational Evaluation of Flow-Induced Abrasion of Blade and Ladle in Kanbara Reactors for Hot Metal Desulfurization / Li Q et al. The Journal of The Minerals, Metals & Materials Society. 2022. Vol. 74. Рp. 1588-1600. DOI: https://doi.org/10.1007/s11837-021-05120-z.

Desulfurization of hot metal by the injection of disperse magnesium through a submerged rotating tuyere / Sigarev E. N., Chernyatevich A. G., Chubin K. I., Zarandiya S. A. Steel in Translation. 2011. Vol. 41(6). Рр. 487-497. DOI: https://doi.org/10.3103/S0967091211060155.

Єськов Д. В., Сігарьов Є. М. Параметри вдування реагентів та закупорювання Т-подібних наконечників фурм. Збірник наукових праць Дніпровського державного технічного університету (технічні науки). 2024. Вип. 1(44). С. 16-26. DOI: https://doi.org/10.31319/2519-2884.44.2024.2.

Розподіл металевих крапель між газовою та шлакової фазами при продуванні ковшової ванни / Сігарьов Є. М., Єськов Д. В., Похвалітий А. А., Манукян Т. А. Збірник наукових праць Дніпровського державного технічного університету (технічні науки). 2022. Вип. 2(41). С. 9-18. DOI: https://doi.org/10.31319/2519-2884.41.2022.1.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.