Дослідження динамічних властивостей непрямого нагрівника нафти як об’єкта автоматичного керування

DOI:

https://doi.org/10.31498/2225-6733.49.2.2024.321350Ключові слова:

шляховий нагрівник нафти, математична модель, система автоматичного керування, лінеаризація, структурна схемаАнотація

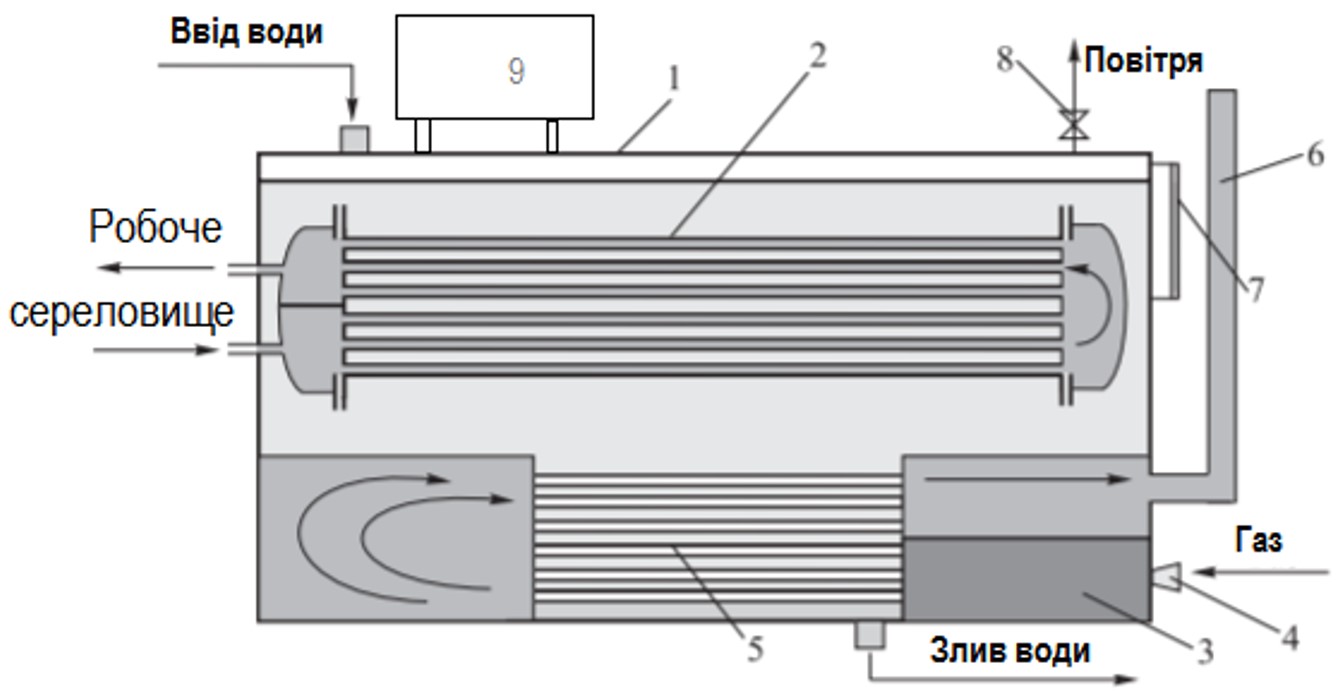

Шляхові нагрівники з проміжним теплоносієм широко використовують для попереднього нагріву нафти та газу з метою зменшення в’язкості нафти при її транспортуванні магістральними трубопроводами або для підігріву газу перед пониженням тиску для запобігання утворення гідратів, які утворюються в результаті ефекту Джоуля-Томпсона. Одним із основних елементів шляхового нагрівника є ванна циліндричної або прямокутної форми, заповнена звичайною водою або з домішками, в якій розміщений змійовик, по якому протікає робоче тіло (нафта). Зазвичай в непрямих нагрівниках використовується звичайна вода. Ванна з водою нагрівається димовими газами, які проходять через жарові труби. Димові гази можуть мати різне походження, такі як спалювання продуктів нафтопереробки, а саме газів після перегонки нафти. Жарові труби конструктивно з’єднані з камерою згорання, де спалюється природний газ. Отже, шляховий нагрівник з проміжним теплоносієм є складною динамічною системою, в якій тепло передається до робочого тіла (нафти) через ряд проміжних ланок. Створена математична модель динаміки шляхового нагрівника з проміжним теплоносієм враховує процеси послідовної передачі тепла від одного елемента до іншого. Кожний елемент в ланцюгу теплопередачі описується нелінійним диференціальним рівнянням, яке отримано на основі закону збереження енергії (тепла). Такий спосіб опису динаміки шляхового нагрівника породжує систему диференціальних рівнянь, в якій крім вхідних і вихідних величин є проміжні змінні, такі як температура проміжного середовища, тобто води, температура стінок змійовика тощо. Після лінеаризації системи диференціальних рівнянь були вилучені проміжні змінні, що дало змогу отримати лінеаризовану математичну модель нагрівника, яка є придатною для синтезу багатоконтурної системи автоматичного керування непрямим нагрівником

Посилання

Rahmati A. R., Reiszadeh M. An experimental study on the effects of the use of multi-walled carbon nanotubes in ethylene glycol/water-based fluid with indirect heaters in gas pressure reducing stations. Applied Thermal Engineering. 2018. Vol. 134. Pp. 107-117. DOI: https://doi.org/10.1016/j.applthermaleng.2018.01.111.

An active approach to heat transfer enhancement in indirect heaters of city gate stations: An experimental modeling / A. Amiri Delouei et al. Applied Thermal Engineering. 2024. Vol. 237. Article 121795. DOI: https://doi.org/10.1016/j.applthermaleng.2023.121795.

Rashidmardani А., Hamzei M. Effect of Various Parameters on Indirect Fired Water Bath Heaters’ Efficiency to Reduce Energy Losses. Science and Engineering Investigations. 2013. Vol. 2. Iss. 12. Pp. 17-24.

Mostafavi S.A., Shirazi M. Thermal modeling of indirect water heater in city gate station of natural gas to evaluate efficiency and fuel consumption. Energy. 2020. № 212. Article 118390. DOI: https://doi.org/10.1016/j.energy.2020.118390.

Khanmohammadi S., Shahsavar A. Thermodynamic assessment and proposal of new configurations of an indirect water bath heater for a City Gate Station (a case study). Energy Equipment and Systems. 2020. Vol. 8. No. 4. Pp. 349-365. DOI: https://doi.org/10.22059/ees.2020.241292.

Performance enhancement of water bath heater at natural gas city gate station using twisted tubes / Soleimani P., Khoshvaght-Aliabadi M., Rashidi H., Bahmanpour H. Chinese Journal of Chemical Engineering. 2020. Vol. 28(1). Pp. 165-179. DOI: https://doi.org/10.1016/j.cjche.2019.03.018.

Failure analysis of carbon steel components in a water bath heater and the influence of ethylene glycol concentration / Shabanian S., Ashrafizadeh F., Saeidi N., Ashrafi A. Engineering Failure Analysis. 2016. Vol. 66. Pp. 533-543. DOI: https://doi.org/10.1016/j.engfailanal.2016.05.015.

Improving thermal performance of water bath heaters in natural gas pressure drop stations / Khosravi M., Arabkoohsar A., Alsagri A.S., Sheikholeslami M. Applied Thermal Engineering. 2019. Vol. 159. Article 113829. DOI: https://doi.org/10.1016/j.applthermaleng.2019.113829.

Design of a simple temperature transmitter circuit of an electric heater operated water bath / Chakraborty S., Bera S. K., Bera S. C., Mandal N. IEEE Sensors Journal. 2018. Vol. 18(8). Pp. 3140-3151. DOI: https://doi.org/10.1109/JSEN.2018.2809465.

Induction heating of petroleum products as an efficient technological process / A. I. Nikitin et al. IOP Conference Series: Materials Science and Engineering. 2020. Vol. 950. Article 012030.

Горбійчук М. І., Когутяк М. І., Гарасимів В. М. Математична модель підігрівника з проміжним теплоносієм. Методи та прилади контролю якості. 2021. № 2(47). С. 83-95. DOI: https://doi.org/10.31471/1993-9981-2021-2(47)-83-95.

Energetic, exergetic, environmental and economic assessment of a novel control system for indirect heaters in natural gas city gate stations / Ebrahimi Moghadam A., Deymi Dashtebayaz M., Jafari H., Niazmand A. Journal of Thermal Analysis and Calorimetry. 2020. Vol. 141. Pp. 2573-2588. DOI: https://doi.org/10.1007/s10973-020-09413-4.

Горбійчук М. І., Василенчук М. З., Когутяк М. І. Синтез лінеаризованих математичних моделей нагрівника з проміжним теплоносієм. Вимірювальна та обчислювальна техніка в технологічних процесах. 2023. Вип. 3. С. 144-153. DOI: https://doi.org/10.31891/2219-9365-2023-75-17.

Горбійчук М. І., Василенчук М. З. Синтез структурної схеми нагрівника нафти як об’єкта автоматичного керування. Вісник Херсонського національного технічного університету. 2023. № 4(87). С. 44-52. DOI: https://doi.org/10.35546/kntu2078-4481.2023.4.5.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.