Комплексна технологія виробництва чорних металів із застосуванням низькотемпературної плазми

DOI:

https://doi.org/10.31498/2225-6733.50.2025.336317Ключові слова:

вуглець, газифікація, низькотемпературна плазма, металізація, плазмохімічний реактор, електродугова піч, електроенергіяАнотація

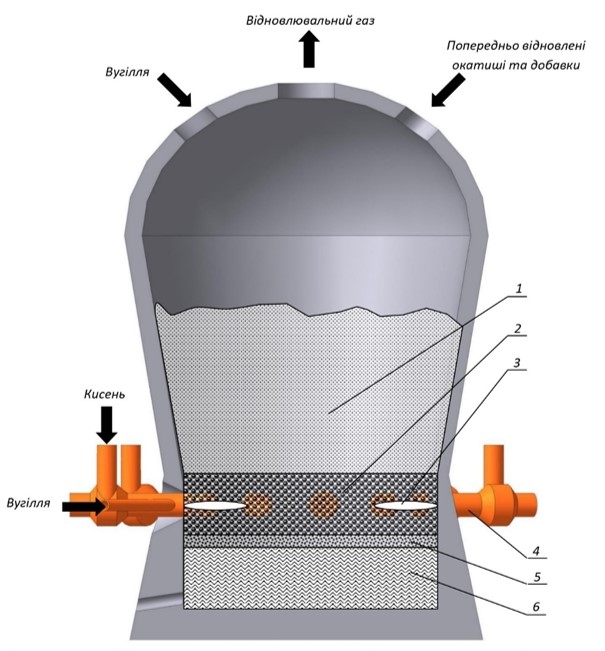

Запропоновано концепцію інноваційного металургійного підприємства, що ґрунтується на низці ключових принципів. Вуглець, що міститься у вугіллі, розглядається переважно як основний відновник для відновлення залізовмісних оксидів. Діоксид вуглецю використовується для газифікації вугілля. Відпрацьовані гази спрямовуються на генерацію електроенергії, яка забезпечує потреби сталеплавильного виробництва, включаючи процеси її розливання та формування. Для підтримання необхідного температурного режиму, що забезпечує ефективне відновлення заліза, застосовується низькотемпературна плазма. Основні технологічні етапи роботи такого інтегрованого заводу – газифікація вугілля, остаточне відновлення залізних оксидів, насичення заліза вуглецем, а також утворення шлаку та чавуну – реалізуються в межах одного пристрою, яким є плазмохімічний плавильний реактор. Продукти газифікації, що утворюються в реакторі, характеризуються високою температурою та сильними відновними властивостями, завдяки чому використовуються для нагріву й металізації окатишів. Виробництво сталі з гарячих металізованих окатишів і чавуну здійснюється в електродуговій печі з використанням електроенергії, отриманої з відпрацьованих після металізації газів, які мають високу температуру та незначний відновлювальний потенціал. Розливання і формування здійснюються за технологією, що виключає проміжне складування заготовок. Кінцевим продуктом такого виробництва є формований метал високої якості, яку неможливо забезпечити при виплавці конвертерним способом. Це приводить до економного споживання енергії та зменшення тривалості робочого циклу. Пропонований інтегрований завод чорної металургії характеризується раціональною схемою використання тепла з мінімізацією його втрат від охолодження агрегатів. Система виділення діоксиду вуглецю та його подальшого використання є найбільш раціональним використанням вуглецю, оскільки, на відміну від традиційних схем, в яких СО2 викидається в атмосферу, в даному випадку він використовується для підвищення вмісту вуглецю в технологічному процесі. Така концепція відповідає сучасним тенденціям світового виробництва сталі

Посилання

Бондаренко Б.И., Шаповалов В.А., Гармаш Н.И. Теория и технология бескоксовой металлургии. К. : Наукова думка, 2003. 535 с.

Бережний М.М., Хіноцька А.А. Паливо та металургійні печі : монографія. Кривий Ріг : Діонат (ФОП Чернявський Д.О.), 2012. 380 с.

Хейфец Р.Г., Куваев Г.Н. Теплоэнергетика металлургических заводов : уч. пособ. Д. : НМетАУ, 2000. 66 с.

4BP Statistical Review of World Energy. June 2014. Energy in 2013: Taking stock. URL: https://www.energypolicy.columbia.edu/sites/default/files/energy/BP-statistical-review-of-world-energy-2014%20(1).pdf (дата звернення: 03.04.2025).

Маркевич К., Омельченко В. Глобальні енергетичні тренди крізь призму національних інтересів України : аналітична доповідь. К. : Заповіт, 2016. 118 с.

Запаси та видобування кам’яного вугілля. URL: https://eiti.gov.ua/resursi-rozvidka-ta-vidobuvannya/kamyane-vugillya_2022/ (дата звернення: 03.04.2025)

Безкоксова металургія заліза : підручник / Іващенко В.П., Величко О.Г., Терещенко В.С., Чеченєв В.А. Дніпропетровськ : РВА «Дніпро-ВАЛ», 2002. 338 с.

Губін Г.В., Півень В О. Сучасні способи безкоксової металургії заліза. Кривий Ріг, 2010. 336 с.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.