Обґрунтування можливостей покращення енергоефективності процесу плавління металу в електродугових печах

DOI:

https://doi.org/10.31498/2225-6733.50.2025.336320Ключові слова:

електродугова піч, енергетичний баланс, ефект Зеєбека, термоелектричний перетворювачАнотація

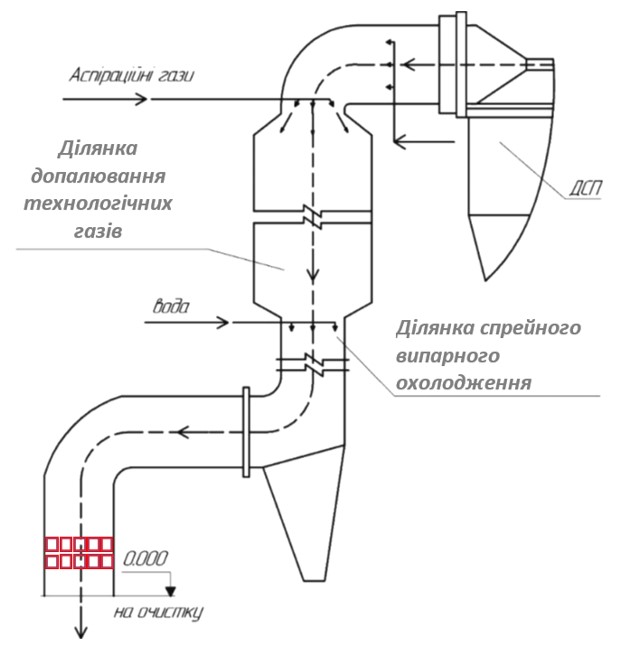

Представлена робота присвячена аналізу можливості повернення частки електричної енергії, що витрачається під час проведення плавки металів в електричних печах, конкретно – в електродугових. Відомо, що при виплавці металу в електропечах (особливо в електродугових) виділяється значна кількість пилу та газів, що мають високу температуру. Вихід газів та їх склад залежить від складу шихти, швидкості плавлення, технологічного та температурного режимів плавки, режиму кисневої продувки та ін. Для електросталеплавильного виробництва є характерним вміст у відхідних від печей газах дрібнодисперсного пилу, який найбільше виділяється під час продувки металу киснем. Інша сторона питання – теплові викиди в навколишнє середовище. Глобальне потепління вимагає швидкого та ефективного вирішення цієї проблеми. Використання тепла, що виноситься з плавильного об’єму електропечей, може, по-перше, дати можливість економити енергоресурси для технологічних цілей «in - situ», а, по-друге, – забезпечувати гарячою водою, парою, електроенергією як зовнішніх промислових, так і побутових споживачів. Одним із перспективних методів утилізації цього тепла є використання термоелектричних явищ, зокрема, ефекту Зеєбека. Обладнання, що працює на цьому ефекті, дозволяє перетворювати теплову енергію в електричну і це може бути використано для підвищення енергоефективності виробництва. У роботі проаналізовані теоретичні засади використання термоелектричних перетворювачів у цілому та при утилізації тепла газів, що відходять від плавильних печей конкретно. На підставі передового досвіду розрахована електрична потужність блока перетворювачів, наведена принципова схема підключення термоелектричних перетворювачів до електромережі та їх монтажна схема

Посилання

Сайт ПрАТ «Дніпроспецсталь». URL: https://www.ua-region/00186536 (дата звернення: 08.02.2025).

Козлов Г.О., Тополов В.Л. Індукційні печі: Навчальний посібник для студентів ВНЗ. Нікополь : НТ НМетАУ, 2008. 32 с.

Enhancing the waste heat utilization of industrial park: A heat pump-centric network integration approach for multiple heat sources and users / W. Wu et al. Energy Conversion and Management. 2024. Vol. 306, Article 118306. DOI: https://doi.org/10.1016/j.enconman.2024.118306.

Литвиненко С.С., Конотопчик І.О. Термоелектричні явища. Ефекти Зеєбека та Пельтьє. Актуальні проблеми фундаментальних і прикладних досліджень: матеріали IIІ Міжнародної інтернет-конференції молодих вчених, м. Луцьк, 12-13 квітня 2021 р. С. 61-62.

d’Angelo M., Galassi C., Lecis N. Thermoelectric Materials and Applications: A Review. Energies. 2023. № 16. Article 6409. DOI: https://doi.org/10.3390/en16176409.

Goldsmid H. Julian. Introduction to Thermoelectricity. Springer Series in Materials Science. 2016. Vol. 121. Berlin, Heidelberg: Springer Berlin Heidelberg. 278 p. DOI: https://doi.org/10.1007/978-3-662-49256-7.

Thermal stability and mechanical response of Bi₂Te₃-based materials for thermoelectric applications / Y. Zheng et al. ACS Applied Energy Materials. 2020. Vol. 3, no. 3. Pp. 2078-2089. DOI: https://doi.org/10.1021/acsaem.9b02093.

Champier D. Thermoelectric generators: A review of applications. Energy Conversion and Management. 2017. Vol. 140. Pp. 167-181. DOI: https://doi.org/10.1016/j.enconman.2017.02.070.

Produkt ERS 200 für Großindustrie und Abwasse-runternehmen. URL: https://www.smarte5.com/ers200/ (дата звернення: 15.12.2024).

Анатичук Л.І. Термоелектрика : в 4 т. Чернівці: Букрек, 2003. Том ІІ : Термоелектричні перетворювачі енергії. 376 c.

Система очищення димових газів електричної печі. URL: http://uk.xiyegroup.com/electric-furnace-dedusting-equipment-product/ (дата звернення: 15.12.2024).

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.